High-solid-content three-coating and one-baking finish paint for automobile based on waterborne acrylic polyurethane

A technology of acrylic polyurethane and water-based polyurethane, applied in the field of coatings, can solve the problems of unsatisfactory coating level, visual fullness, appearance data indicators, low standards, and high paint consumption per vehicle, and achieve excellent construction application The effect of performance, low VOC content, and excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The particle size of the dispersion particle of the aqueous acrylic polyurethane emulsion A is 60-150 nm, the solid acid value is 10-20 mgKOH / g, and the hydroxyl value is 20-50 mgKOH / g (exemplarily, the hydroxyl value includes but is not limited to 25 ~50mgKOH / g, 25~45mgKOH / g, 25~40mgKOH / g, 25~35mgKOH / g, 30~50mgKOH / g, 35~50mgKOH / g, 40~50mgKOH / g, etc.). The preparation method of this water-based acrylic polyurethane emulsion A comprises the following steps:

[0033] In a preferred example, the preparation of the water-based acrylic polyurethane emulsion A includes the following steps:

[0034] Under nitrogen protection, mix water-based polyurethane A, emulsifier and water, stir and heat up to 70-90°C to obtain the first mixture;

[0035] Add the acrylic monomers to the water in which the emulsifier is dissolved in turn, and stir to make the acrylic monomers fully pre-emulsified to obtain the monomer pre-emulsion;

[0036] At a temperature of 70-90 °C, part of the monom...

Embodiment 1

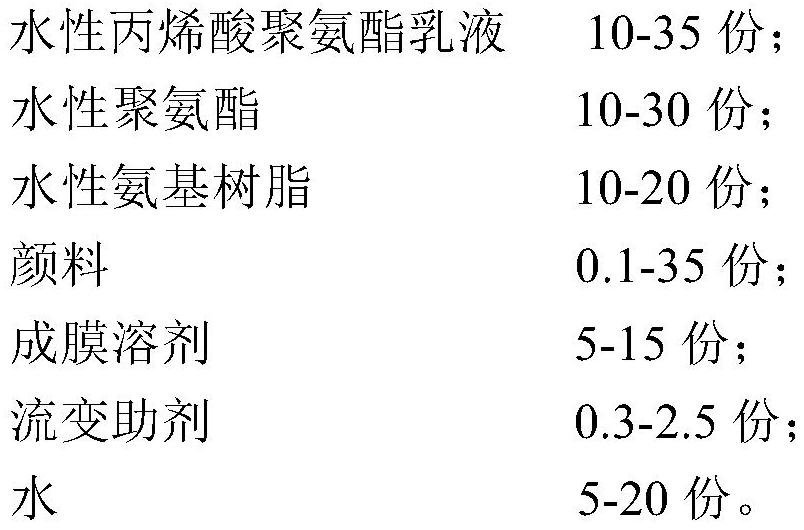

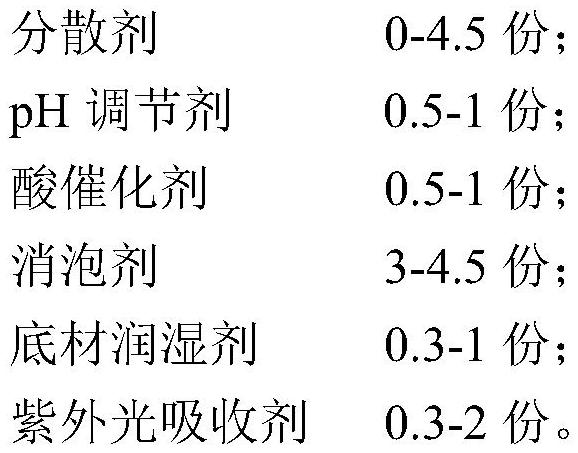

[0090] A high-solid three-coat-one-bake intermediate coating for automobiles based on water-based acrylic polyurethane consists of the following components in corresponding parts by mass:

[0091]

[0092] Wherein, the hydroxyl value (based on solid content) of the water-based acrylic emulsion is 5-20 mgKOH / g, the pH value is 6.5-7.8, the particle size is 90-150 nm, and the solid acid value is 10-20 mgKOH / g.

[0093] The water-based polyurethane resin is gradually polycondensed and polymerized by polyester prepolymer and polyisocyanate monomer to obtain a polymer with uniform particle size distribution, its hydroxyl value (based on solid content) is 100-150 mgKOH / g, and the pH value is between 100 and 150 mgKOH / g. 6.5 to 7.8, the resin particle size is 30 to 60 nm, and the solid acid value is 10 to 20 mgKOH / g.

[0094] The water-based amino resin is commercially available Cymel 303 resin.

[0095] The pigment is titanium dioxide CR-97 resin-free color paste, which does not...

Embodiment 2

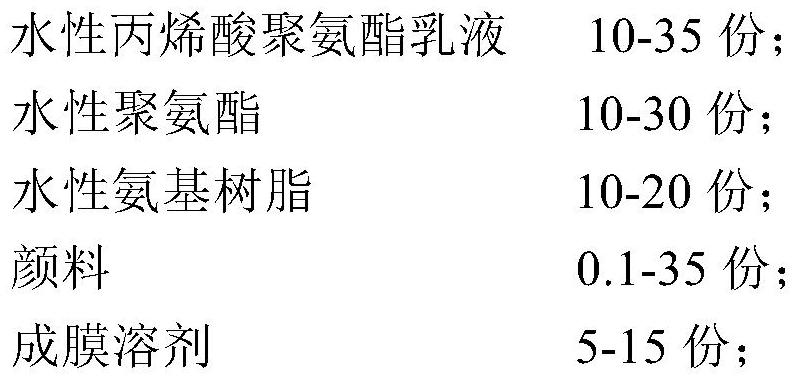

[0108] A high-solid three-coat-one-bake topcoat for automobiles based on waterborne acrylic polyurethane, consisting of the following components according to the corresponding mass percentages:

[0109]

[0110] The resin in the water-based acrylic polyurethane emulsion is water-based acrylic polyurethane emulsion A and allnex China's DAOTAN VTW 6462 / 36WA, and the mass ratio of the two is 2 / 1. Wherein, the hydroxyl value (based on solid content) of the aqueous acrylic polyurethane emulsion A is 20-50 mgKOH / g, and the pH value is 6.5-9.0. This resin is co-polymerized by acrylic polymer and urethane polymer to form an interpenetrating network structure of acrylic and urethane. The particle diameter of the dispersion particles is 60-150 nm, and the acid value of the solid content is 10-20 mgKOH / g.

[0111] Described waterborne polyurethane resin is waterborne polyurethane A and The mixture of U XP 2755 resin, the mass ratio of the two is 8:7. Among them, the hydroxyl value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com