Production method of porous copper micron hollow sphere current collector

A production method and technology of hollow spheres, applied in the direction of electrode carrier/collector, structural parts, transportation and packaging, etc., can solve the problem of affecting the life, safety and energy density of lithium batteries, hindering the mass specific capacity and volume specific capacity of batteries, and battery Energy has no contribution and other issues, to achieve the effect of preventing short circuit, reducing mass, and simplifying production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

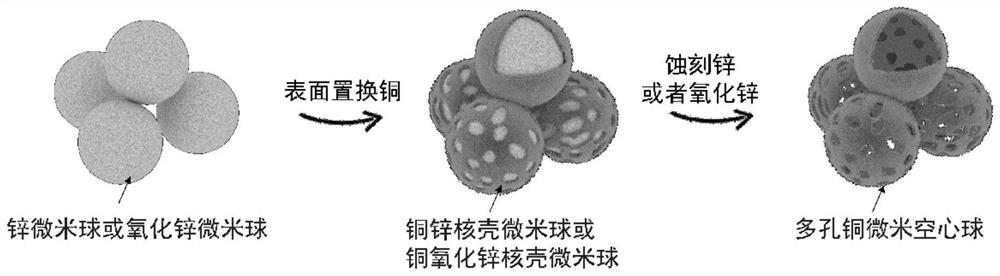

[0039] One kilogram of commercial 5-micron zinc powder, 0.5 kilograms of copper acetylacetonate, and 9.5 kilograms of ethylene glycol are taken, copper acetylacetonate is dissolved in ethylene glycol, and zinc powder is added to obtain a mixed solution. The solution was reacted at 160 °C for 4 h by means of an oil bath, annealed at 250 °C after the replacement reaction, and then etched in a 5% volume fraction of dilute hydrochloric acid solution for 30 min to obtain porous copper micro hollow sphere powder with regular shape.

[0040] 1 kg of porous copper micron hollow sphere powder was washed three times with ultrapure water, ethanol and acetone respectively to remove impurities such as grease on the surface, and the product obtained after cleaning was vacuum dried for 6 hours to obtain the treated hollow copper particles.

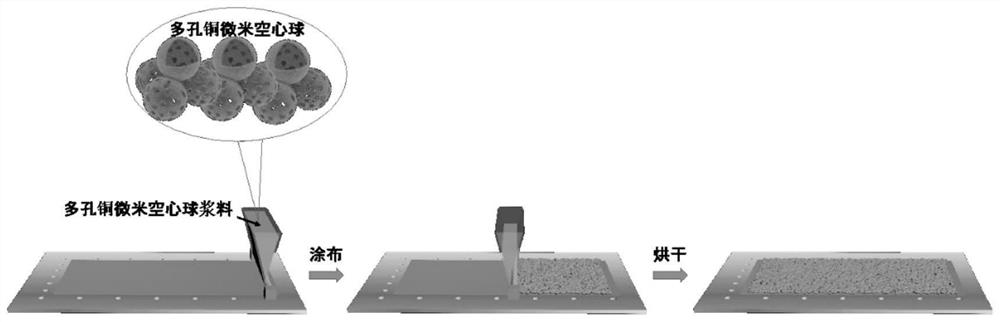

[0041] Take 1 kg of porous copper micron hollow sphere powder after treatment and put it into a glass container, then add 100 grams of PVDF as a binder a...

Embodiment 2

[0045] One kilogram of commercial 5-micron zinc oxide powder, 0.5 kilograms of copper acetylacetonate, and 9.5 kilograms of ethylene glycol are taken, copper acetylacetonate is dissolved in ethylene glycol, and zinc oxide powder is added to obtain a mixed solution. The solution was reacted at 160 °C for 4 h by means of an oil bath, annealed at 250 °C after the replacement reaction, and then etched in a 5% volume fraction of dilute hydrochloric acid solution for 30 min to obtain porous copper micro hollow sphere powder with regular shape.

[0046] Take 1 kg of porous copper micron hollow sphere powder and wash it three times with ultrapure water, ethanol and acetone respectively to remove impurities such as grease on the surface.

[0047] Take 1 kg of porous copper micron hollow sphere powder after treatment and put it into a glass container, then add 100 grams of PVDF as a binder and 0.5 kg of NMP as a solvent, and stir evenly to obtain a porous copper micron hollow sphere powd...

Embodiment 3

[0051] One kilogram of commercial 5-micron zinc powder, 0.5 kilograms of tetraamine copper sulfate, and 9.5 kilograms of ethylene glycol are taken, tetraamine copper sulfate is dissolved in ethylene glycol, and zinc powder is added to obtain a mixed solution. The solution was reacted at 160 °C for 4 h by means of an oil bath, annealed at 250 °C after the replacement reaction, and then etched in a 5% volume fraction of dilute hydrochloric acid solution for 30 min to obtain porous copper micro hollow sphere powder with regular shape.

[0052] 1 kg of porous copper micron hollow sphere powder was washed three times with ultrapure water, ethanol and acetone respectively to remove impurities such as grease on the surface, and the product obtained after cleaning was vacuum dried for 6 hours to obtain the treated hollow copper particles.

[0053] Take 1 kg of porous copper micron hollow sphere powder after treatment and put it into a glass container, then add 100 grams of PVDF as a bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com