Hyperbranched polysiloxane modified lignin compatilizer as well as preparation method and application thereof

A technology of polysiloxane and lignin, which is applied in the field of hyperbranched polysiloxane modified lignin compatibilizer and its preparation, and can solve problems such as easy agglomeration, insufficient performance of original lignin, and poor interfacial compatibilization effect , to achieve the effect of high chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

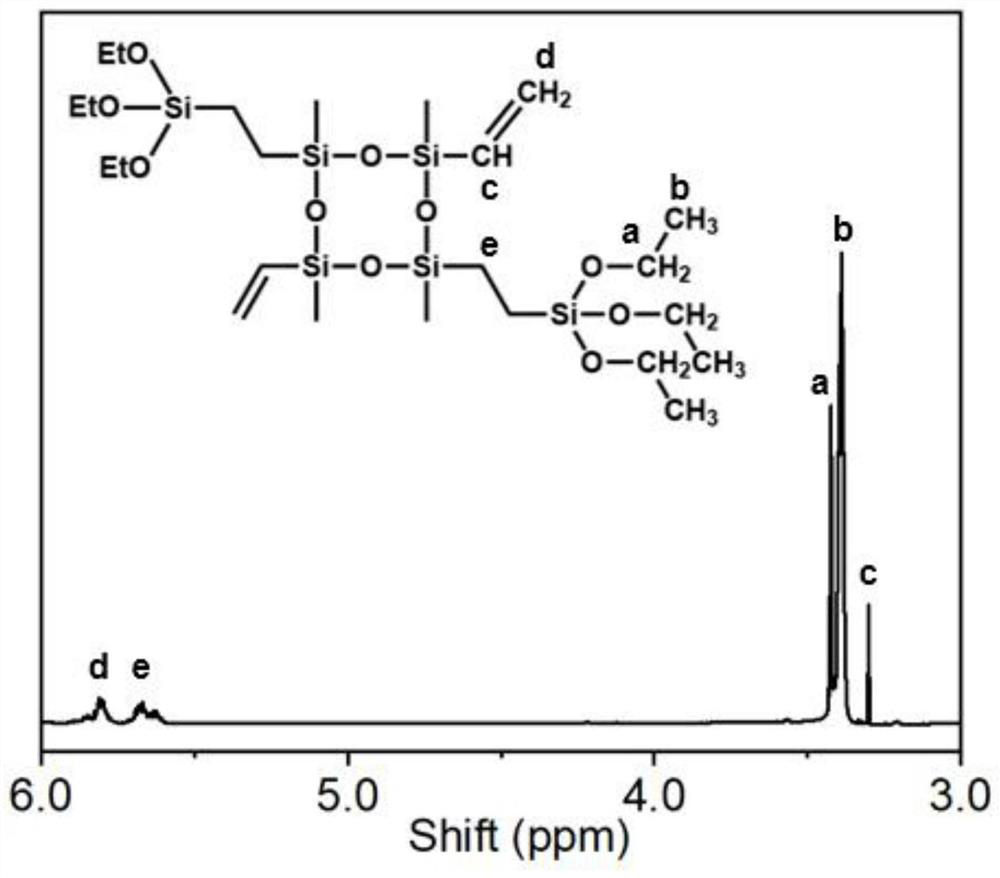

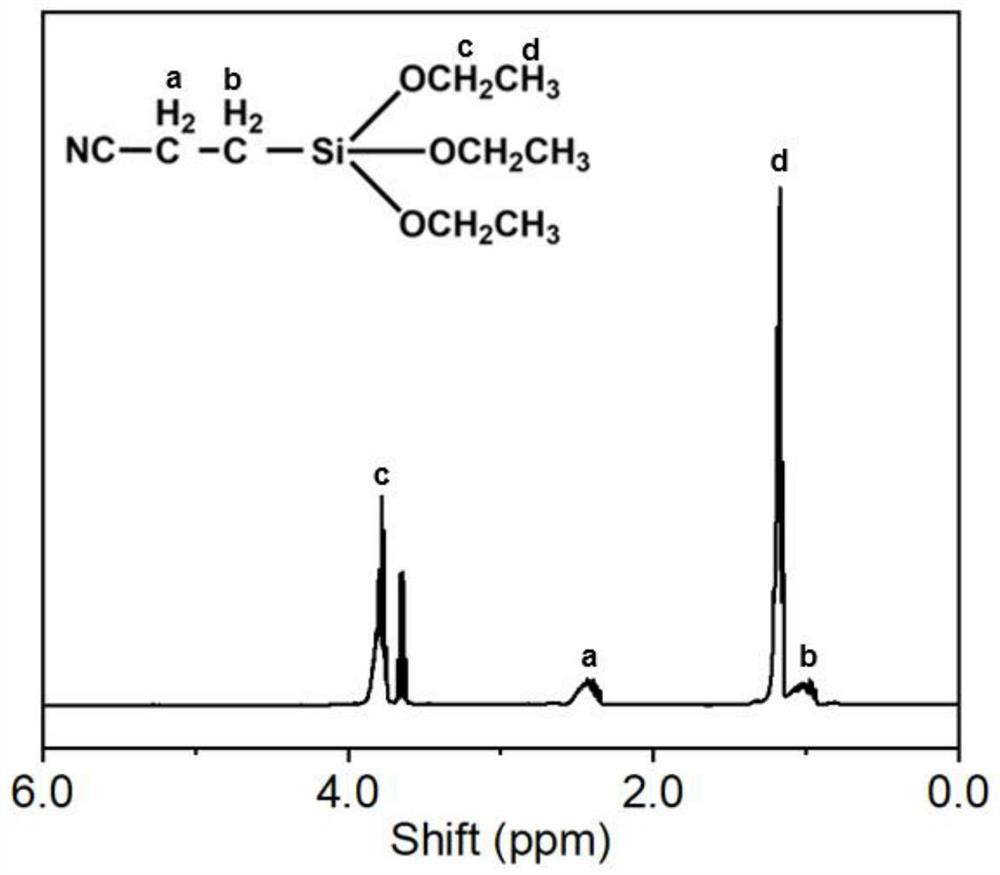

[0094] Preparation of HBPSi with different end groups

[0095] Preparation of ethoxy hyperbranched polysiloxane

[0096] (1) 40g 1,3,5,7-tetraethylene-1,3,5,7-tetramethylcyclotetrasiloxane and 0.1g Karstedt catalyst were dispersed in 15mL methanol to give a mixed solution;

[0097] (2) The mixed solution of step (1) is stirred in an argon atmosphere at 60 °C for reflux; Then slowly add 15mL of methanol solution containing 25g of triethoxysilane, stir for 12h, and obtain a transparent silane oligomer by filtering and rotating evaporation;

[0098] (3) The silane oligomers in step (2) were mixed uniformly with maleic anhydride and Karstedt catalysts in the desired proportion (the molar ratio of maleic anhydride to silane oligomers was 1.5:1, and the molar ratio of Karstedt catalyst to silane oligomers was 0.15%:1), and the mixture was obtained;

[0099] (4) The mixture of step (3) is loaded into a four-well bottle filled with argon gas for conversion and kept at 60 °C for 12 h for t...

Embodiment 1

[0108] (1) Weigh the synthesized 3g EtO-HBPSi and 86g of o-xylene and mix evenly to obtain EtO-HBPSi / o-xylene mixture;

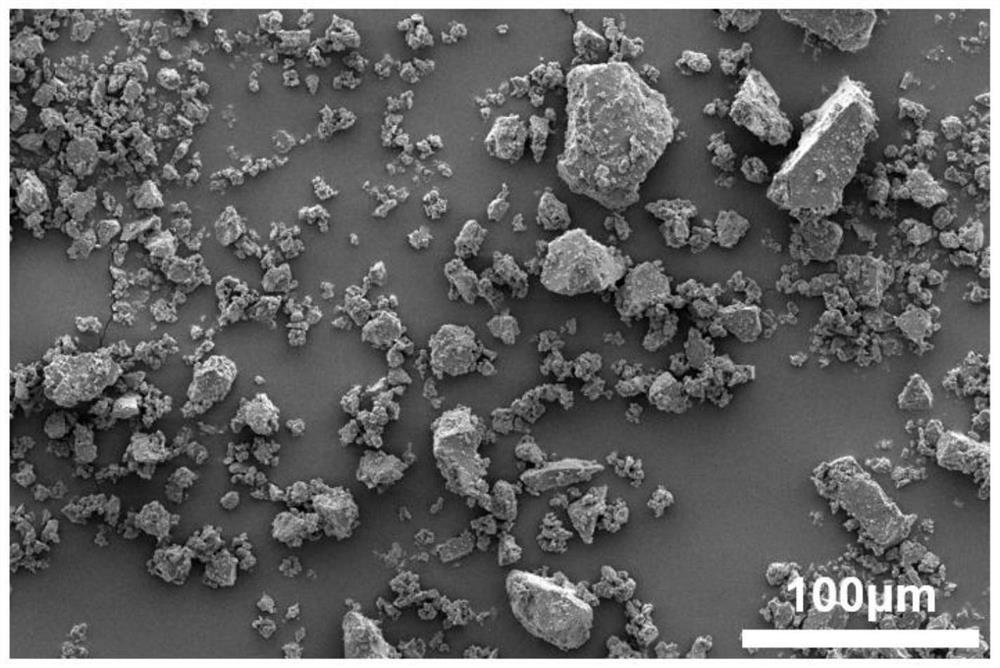

[0109] (2) Add 40g of organic lignin to the EtO-HBPSi / o-xylene mixture in step (1) and after ultrasonic dispersion for 15 min, an EtO-HBPSi / o-xylene / lignin mixture was obtained;

[0110] (3) The EtO-HBPSi / o-xylene / lignin mixture of step (2) was placed in an oil bath pot at 85 °C for condensation and reflux for 5h;

[0111] (4) At the end of condensation reflux, the lignin- (EtO-HBPSi) is filtered out using a suction filter device, and the filtration is washed and filtered 5 times with deionized water, and then freeze-dried under a vacuum environment of -70 °C for 48h to obtain lignin- (EtO-HBPSi), that is, a degradable ethoxy hyperbranched polysiloxane modified lignin compatilin compatient.

Embodiment 2

[0113] (1) Weigh the synthesized 3g EtO-HBPSi and 86g of o-xylene and mix evenly to obtain EtO-HBPSi / o-xylene mixture;

[0114](2) Add 90g of organic lignin to the EtO-HBPSi / o-xylene mixture in step (1) and after ultrasonic dispersion for 15 min, the EtO-HBPSi / o-xylene / lignin mixture was obtained;

[0115] (3) The EtO-HBPSi / o-xylene / lignin mixture of step (2) was placed in an oil bath pot at 85 °C for condensation and reflux for 5h;

[0116] (4) At the end of condensation reflux, the lignin- (EtO-HBPSi) is filtered out by means of a suction filter device, and the filtration is washed and filtered 5 times with deionized water, and then freeze-dried under a vacuum environment of -70 °C for 48h to obtain lignin- (EtO-HBPSi), that is, a degradable ethoxy hyperbranched polysiloxane modified lignin compatibilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com