Closed self-circulation heat transfer device and application thereof

A self-circulating and closed technology, applied in the direction of heat exchange materials, cooling/ventilation/heating transformation, chemical instruments and methods, etc., can solve problems such as equipment failure, heat generation increase, base station operating temperature rise, etc. Thermal efficiency and heat transfer effect, moderate saturated vapor pressure, good heat dissipation and uniform temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This implementation examines the deformation of the closed self-circulating heat transfer device after being filled with the working fluid.

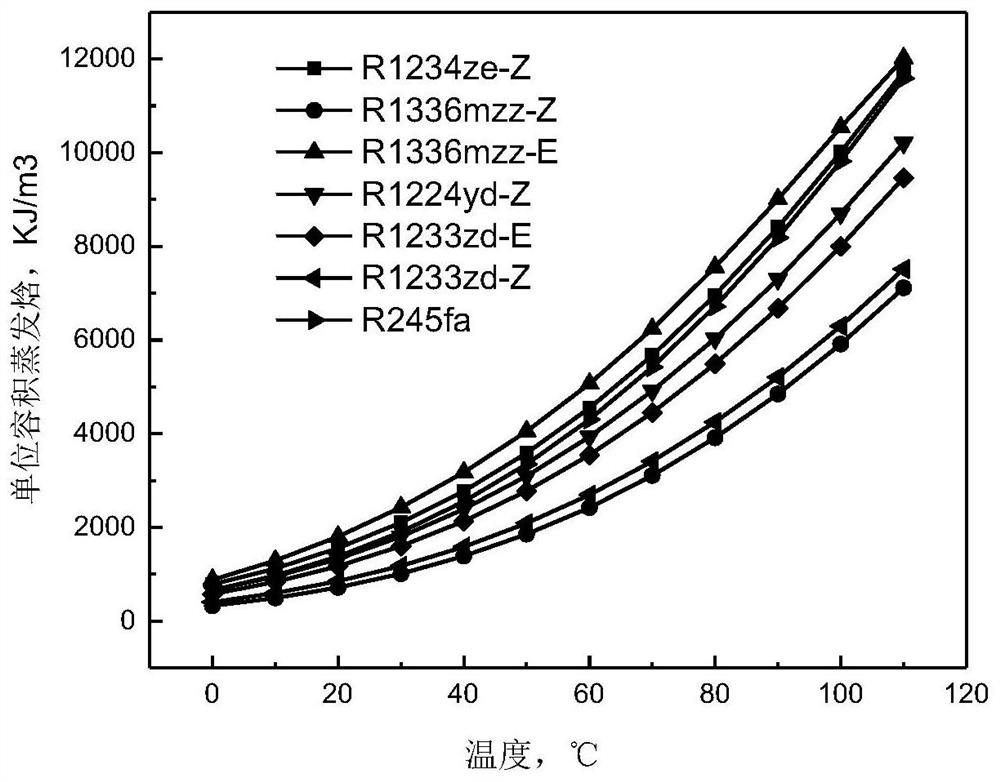

[0054] In the temperature range of 0 to 110 °C, the working fluid is filled in the closed self-circulating heat transfer device, and the deformation of the heat transfer device is shown in Table 2 below:

[0055] Table 2 Deformation of heat transfer device

[0056]

[0057]

[0058] It can be seen from Table 2 that when the temperature is not higher than 110 °C, the closed self-circulating heat transfer device is not deformed after filling with each working fluid, which ensures the stable operation of the heat transfer device under various working conditions. Among the working fluids, HFO-1234ze(Z) has the smallest filling amount, which can reduce the use cost.

Embodiment 2

[0060] In this implementation, the heat dissipation and temperature resistance performance and the anti-aging performance of the closed self-circulating heat transfer device were investigated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com