Wear-resistant asphalt-based waterproof coating and preparation method thereof

A waterproof coating, bitumen-based technology, used in bitumen coatings, fire-retardant coatings, coatings, etc., can solve problems such as asphalt aging, construction difficulties, and carcinogen benzopyridine volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

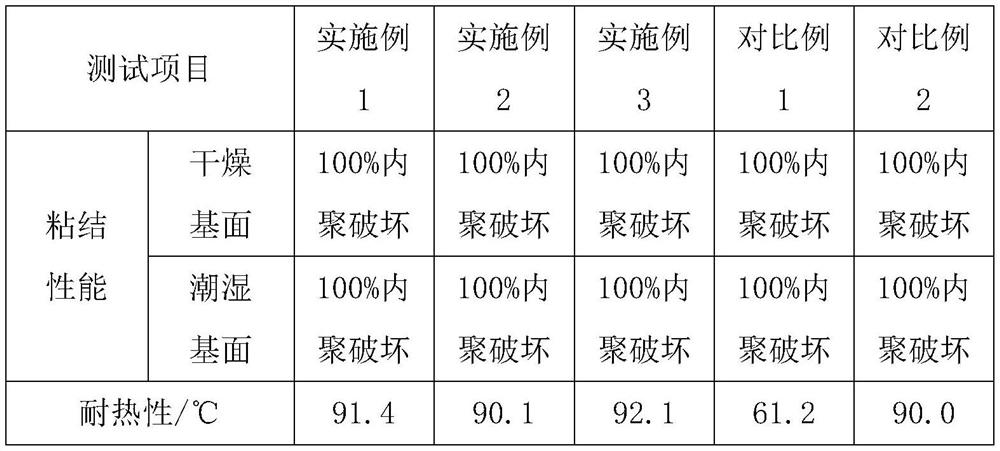

Embodiment 1

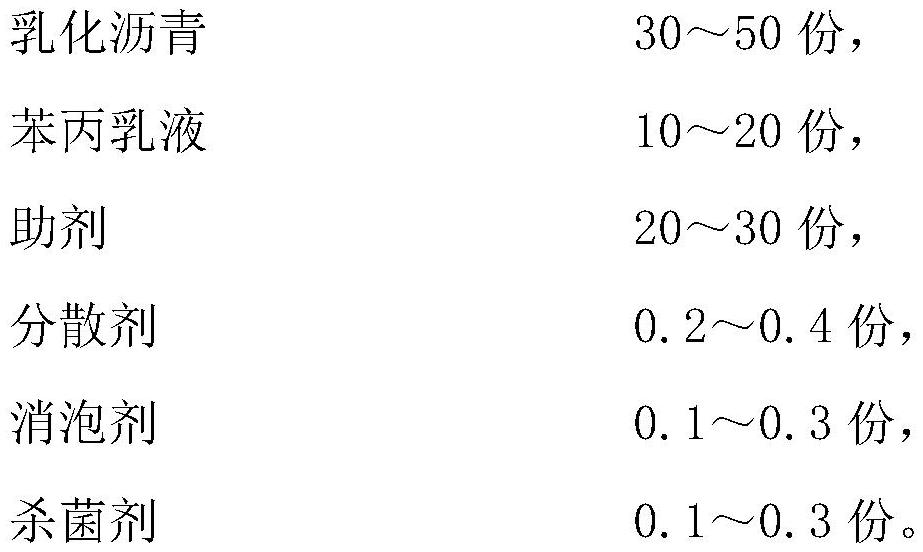

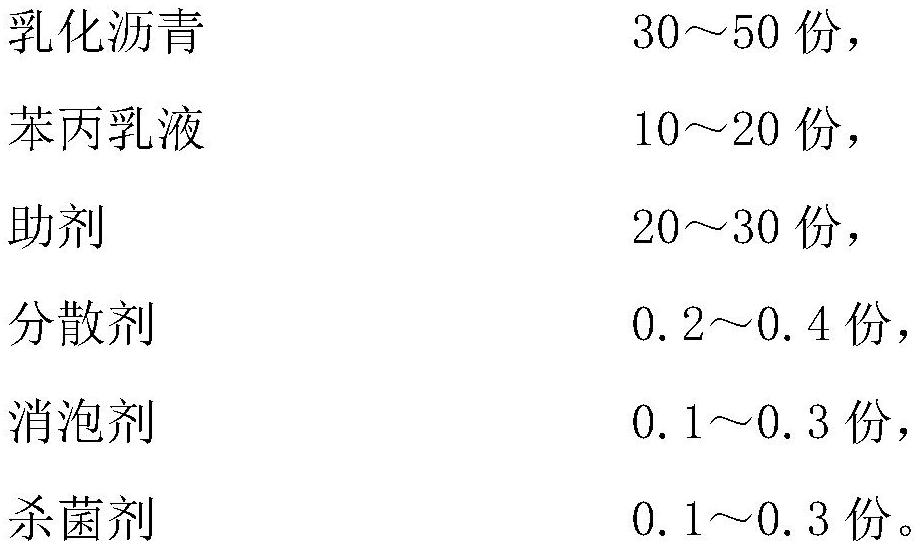

[0015] A wear-resistant asphalt-based waterproof coating, in parts by weight, its raw material composition includes: 30 parts of emulsified asphalt, 10 parts of styrene-acrylic emulsion, 20 parts of auxiliary agents, 0.2 parts of dispersant, 0.1 part of defoamer, and 0.1 part of bactericide. 1 part of silica fume, 1 part of magnesium aluminum silicate; the additives include tire powder and silicon carbide micropowder, and the weight ratio of the tire powder and silicon carbide micropowder is 1:1; the emulsified asphalt is cationic emulsified asphalt .

[0016] A method for preparing a wear-resistant asphalt-based waterproof coating, comprising the steps of:

[0017] S1, put emulsified asphalt and styrene-acrylic emulsion into the reaction kettle and stir to obtain mixed emulsion;

[0018] S2, add the auxiliary agent into the mixed emulsion and stir evenly;

[0019] S3, adding the remaining components to the product obtained in step S2 and stirring evenly to obtain the waterp...

Embodiment 2

[0021] A wear-resistant asphalt-based waterproof coating, in parts by weight, its raw material composition includes: 50 parts of emulsified asphalt, 20 parts of styrene-acrylic emulsion, 30 parts of auxiliary agents, 0.4 parts of dispersant, 0.3 parts of defoamer, and 0.3 parts of bactericide. 5 parts of silica fume, 5 parts of magnesium aluminum silicate; the auxiliary agents include tire powder and silicon carbide micropowder, and the weight ratio of the tire powder and the silicon carbide micropowder is 1:1; the emulsified asphalt is a cationic emulsified asphalt .

[0022] A method for preparing a wear-resistant asphalt-based waterproof coating, comprising the steps of:

[0023] S1, put emulsified asphalt and styrene-acrylic emulsion into the reaction kettle and stir to obtain mixed emulsion;

[0024] S2, add the auxiliary agent into the mixed emulsion and stir evenly;

[0025] S3, adding the remaining components to the product obtained in step S2 and stirring evenly to ...

Embodiment 3

[0027] A wear-resistant asphalt-based waterproof coating, in parts by weight, its raw material composition includes: 35 parts of emulsified asphalt, 15 parts of styrene-acrylic emulsion, 25 parts of auxiliary agents, 0.3 parts of dispersant, 0.2 parts of defoamer, and 0.2 parts of bactericide parts, 3 parts of silica fume, and 2 parts of magnesium aluminum silicate; the additives include tire powder and silicon carbide micropowder, and the weight ratio of the tire powder and silicon carbide micropowder is 1:1; the emulsified asphalt is cationic emulsified asphalt .

[0028] A method for preparing a wear-resistant asphalt-based waterproof coating, comprising the steps of:

[0029] S1, put emulsified asphalt and styrene-acrylic emulsion into the reaction kettle and stir to obtain mixed emulsion;

[0030] S2, add the auxiliary agent into the mixed emulsion and stir evenly;

[0031] S3, adding the remaining components to the product obtained in step S2 and stirring evenly to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com