Metal material cutting and trimming device for lithium battery and manufacturing process of metal material cutting and trimming device

A metal material and lithium battery technology, applied in other manufacturing equipment/tools, manufacturing tools, battery electrodes, etc., can solve problems such as difficult control, human injury, adsorption on the top of the battery metal sheet, etc., to improve efficiency and ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following:

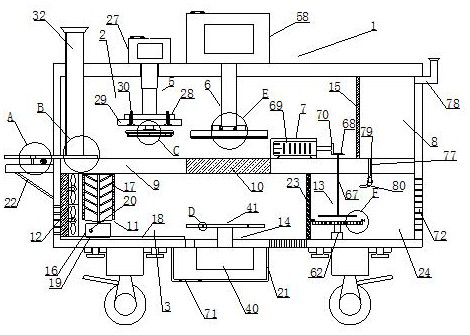

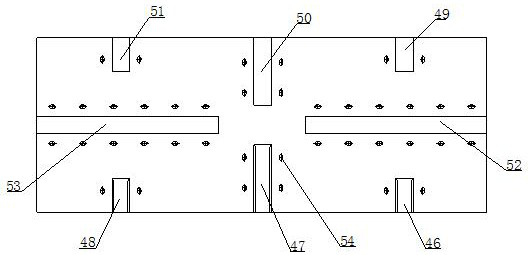

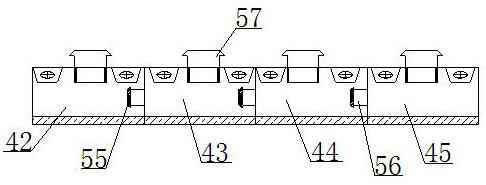

[0044] like Figures 1~10 As shown, a metal material cutting and trimming device for lithium batteries includes a processing box 1, an upper cavity 2 and a lower cavity 3 are arranged inside the processing box 1, and the bottom of the processing box 1 is provided with an upper cavity 2 and a lower cavity 3. The detachable universal wheel ensures the convenient transfer of the processing box 1. The upper cavity 2 is provided with a pushing device 4, a cutting device 5, a pressing device 6, a motor box 7 and a cleaning device 8. The mutual cooperation between the device 4 and the cutting device 5 ensures that the battery metal sheet can be pushed out at the same time as the battery metal sheet is pushed to the right under the cutting device 5, and a separator is provided between the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com