Special filler for marble glue and preparation method thereof

A technology of marble glue and wollastonite powder, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of poor toughness, large temperature difference, and easy brittleness of marble glue, and achieve improvement Effects of hardness, reduction of oil absorption value, and improvement of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

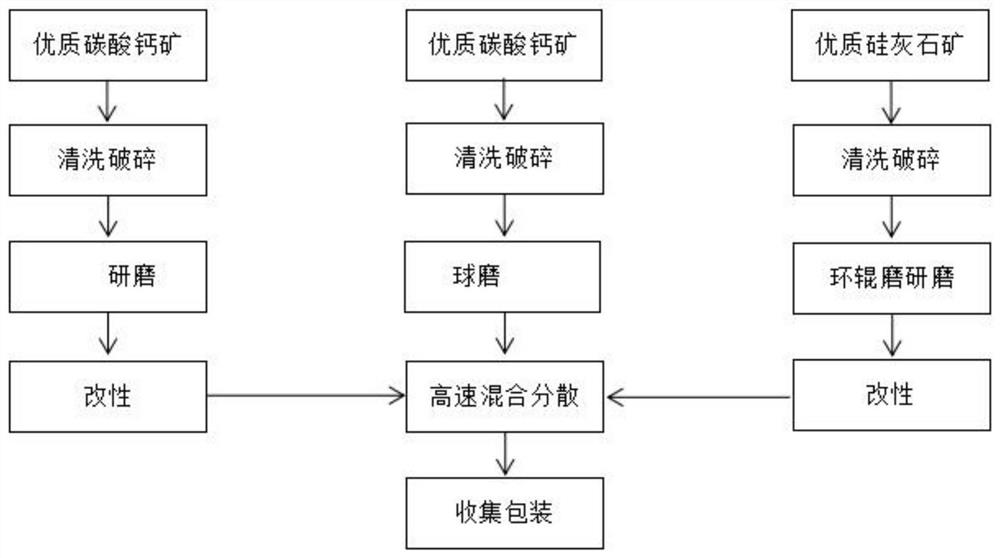

[0027] The invention provides a preparation method of a special filler for marble glue, comprising the following steps:

[0028] The calcium carbonate ore is mixed with sodium acrylate and then ground to obtain a first powder; the particle size of the first powder is 4-6 μm;

[0029] The calcium carbonate ore is mixed with sodium acrylate and then ball-milled to obtain a second powder; the particle size of the second powder is 1.2-2.5 μm;

[0030] The wollastonite is pulverized to obtain wollastonite powder;

[0031] Mixing the first powder, titanate and stearic acid for first modification to obtain a first modified powder;

[0032] Mixing the wollastonite powder and titanate for a second modification to obtain a second modified powder;

[0033] The second powder, the first modified powder and the second modified powder are mixed to obtain the special filler for marble glue.

[0034] In the present invention, unless otherwise specified, the raw materials used are all commer...

Embodiment 1

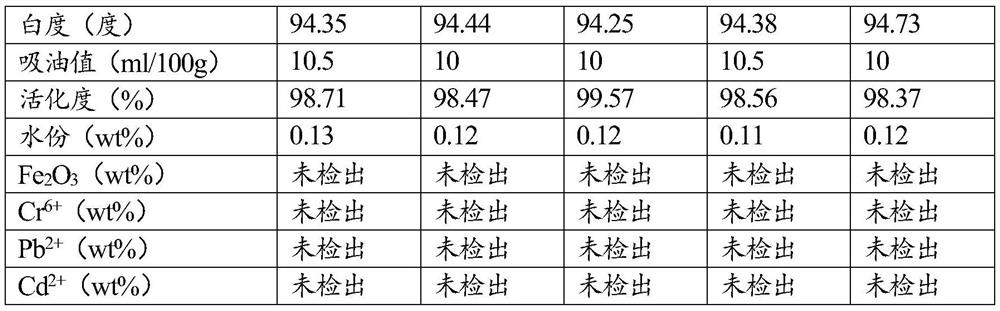

[0071] The calcium carbonate ore is washed and crushed in multiple stages to obtain calcium carbonate particles with a size of 5-10 mm. The obtained particles are ground by grinding or ball mill, adding 2wt‰ sodium acrylate as a grinding aid, and by controlling the rotating speed and classifying the classifier, the obtained Calcium carbonate powders with an average particle size of 5μm and 2μm were modified by a high-speed disperser by adding 3wt‰ titanate and 8wt‰ stearic acid to calcium carbonate with an average particle size of 5μm. The high-quality wollastonite ore is cleaned and multi-stage crushed to obtain wollastonite particles with a size of 5-10 mm. The wollastonite particles are ground by a ring roller mill, and acicular silicon with a crystal length of 20 μm is obtained by controlling the rotation speed and classification. The obtained acicular wollastonite was added to 5wt‰ titanate and modified by a high-speed disperser. The modified 5μm calcium carbonate, 2μm ca...

Embodiment 2

[0077] The calcium carbonate ore is washed and crushed in multiple stages to obtain calcium carbonate particles with a size of 5-10 mm. The obtained particles are passed through a ball mill, and 2wt‰ sodium acrylate is added as a grinding aid for grinding, and the average particle size is obtained by controlling the rotating speed and classifying the classifier Calcium carbonate powders with diameters of 5μm and 2μm were prepared by adding 3wt‰ titanate and 8wt‰ stearic acid to calcium carbonate with an average particle size of 5μm and modified by a high-speed disperser. The high-quality wollastonite ore is washed and crushed in multiple stages to obtain wollastonite particles with a size of 5-10mm. The wollastonite particles are ground by a ring roller mill, and acicular silicon with a crystal length of 20μm is obtained by controlling the rotation speed and classification. The obtained acicular wollastonite was added to 5‰ titanate and modified by a high-speed disperser. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com