A magnetorheological polishing device for metal surface treatment and using method thereof

A technology of metal surface treatment and magnetorheological polishing, applied in surface polishing machine tools, grinding/polishing safety devices, machine tools suitable for grinding workpiece edges, etc. Achieve the effect of reducing cracks, improving mirror polishing effect, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

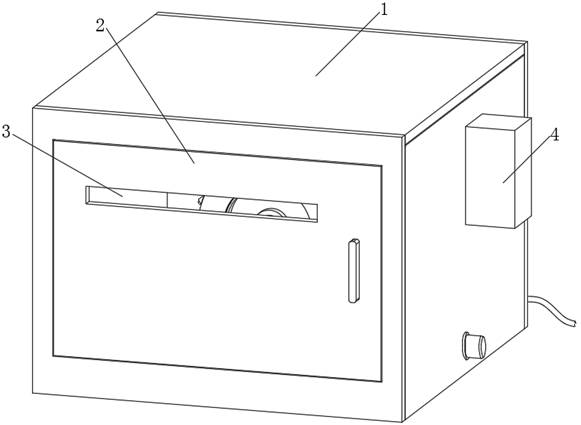

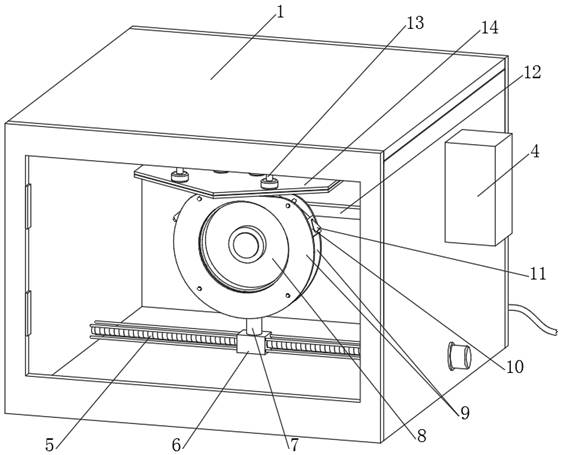

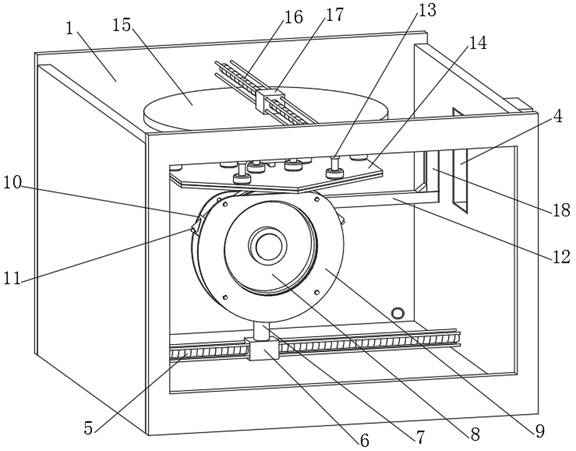

[0051] like figure 1 , figure 2 , image 3 , Figure 4 , Image 6 and Figure 7 As shown, a magnetorheological polishing device for metal surface treatment disclosed in the present invention includes an equipment body 1, and a first telescopic cylinder 7 is vertically arranged in the equipment body 1. The lower part of the first telescopic cylinder 7 is along the An X-axis adjustment assembly is provided in the X-axis direction. The first telescopic cylinder 7 is driven and adjusted in position by the X-axis adjustment assembly. A rotatable grinding wheel 8 is vertically connected to the top of the first telescopic cylinder 7 through a first connecting assembly.

[0052] Located above the grinding wheel 8, a Y-axis adjustment component is installed in the equipment body 1 along the Y-axis direction, and the bottom end of the Y-axis adjustment component is provided with a mirror surface connection component. The mirror surface to be polished is fixed at the bottom end of t...

Embodiment 2

[0080] like figure 1 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown in the figure, a magnetorheological polishing device for metal surface treatment includes an equipment body 1, and a first telescopic cylinder 7 is vertically arranged in the equipment body 1, and a lower part of the first telescopic cylinder 7 is provided along the X-axis direction. X-axis adjustment assembly, the first telescopic cylinder 7 is driven and adjusted by the X-axis adjustment assembly, and the top of the first telescopic cylinder 7 is vertically connected with a rotatable grinding wheel 8 through a first connection assembly.

[0081] Located above the grinding wheel 8, a Y-axis adjustment component is installed in the equipment body 1 along the Y-axis direction, and the bottom end of the Y-axis adjustment component is provided with a mirror surface connection component. The mirror surface to be polished is fixed at the bottom end of the mirror surface connection component, and above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com