Special-shaped workpiece machining equipment and machining process thereof

A technology for special-shaped workpieces and processing equipment, which is applied in the direction of improving process efficiency, can solve problems such as low workpiece quality, and achieve the effects of difficult machining accuracy, improved machining quality, and high machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present application will be further described in detail below with reference to the accompanying drawings.

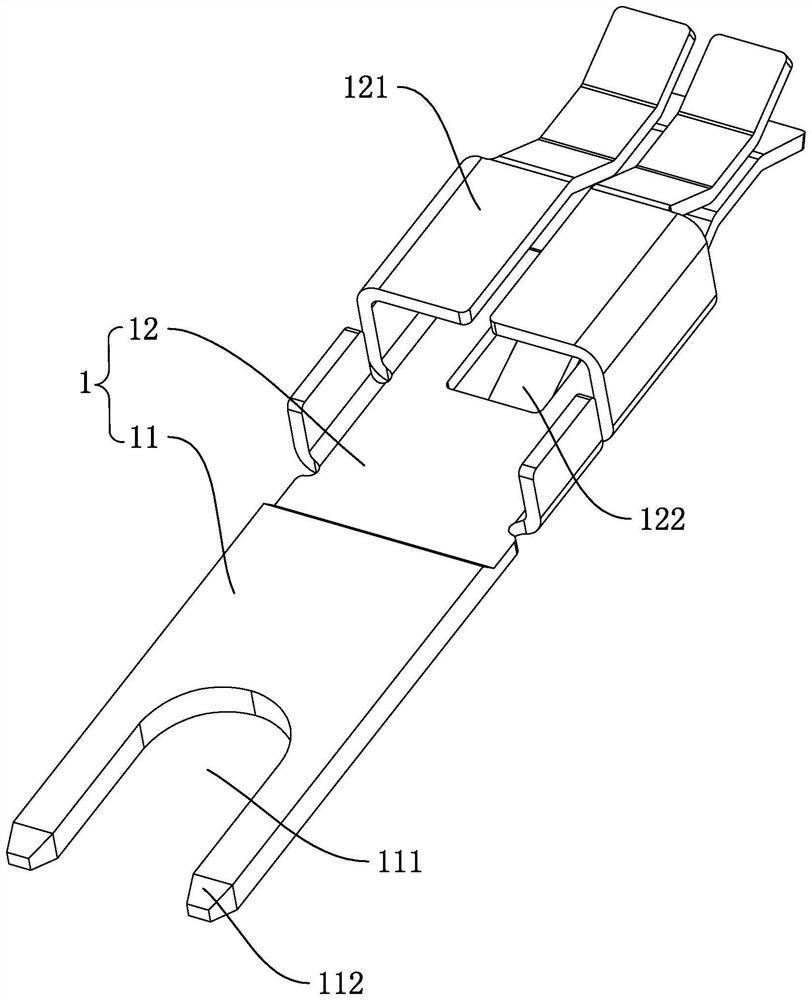

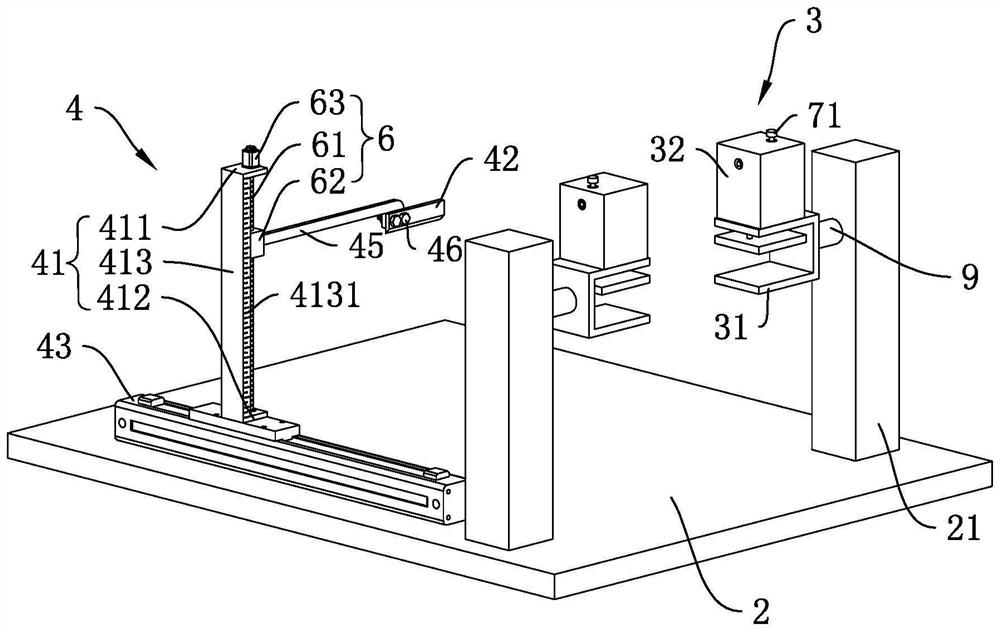

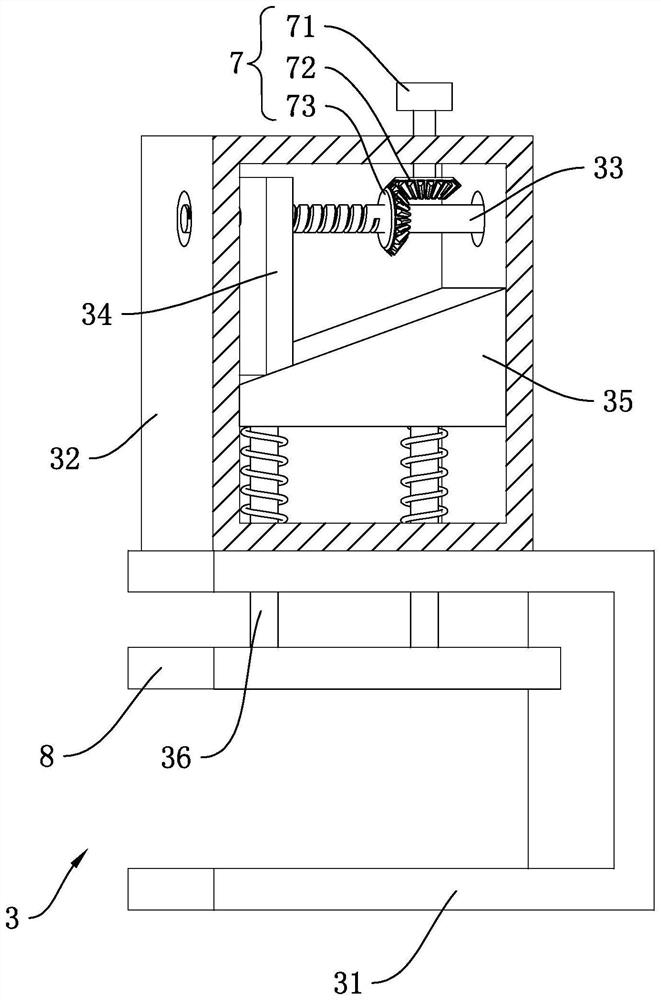

[0032] The embodiment of the present application discloses a processing equipment for a special-shaped workpiece, and the processing equipment for a special-shaped workpiece is used for processing such as figure 1 The shown special-shaped workpiece 1 is used to scrape the material plate. This equipment is set before the equipment for punching the material plate. By taking the lead in scraping the material plate, the subsequent material plate can be freed from the double-layer part. Go to the step of bending the two sides of the sheet inwards 180 degrees. The special-shaped workpiece 1 includes a single-layer portion 12 and a double-layer portion 11 , and the end portion of the single-layer portion 12 is fixedly connected with the end portion of the double-layer portion 11 . One end of the double layer portion 11 away from the single layer portion 12 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com