Multi-directional repeated extrusion deformation processing device and procesisng method for magnesium alloy profile

A technology of repeated extrusion and processing methods, applied in the direction of metal extrusion dies, etc., to achieve the effect of convenient operation, avoiding stress concentration, uniform and fine grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

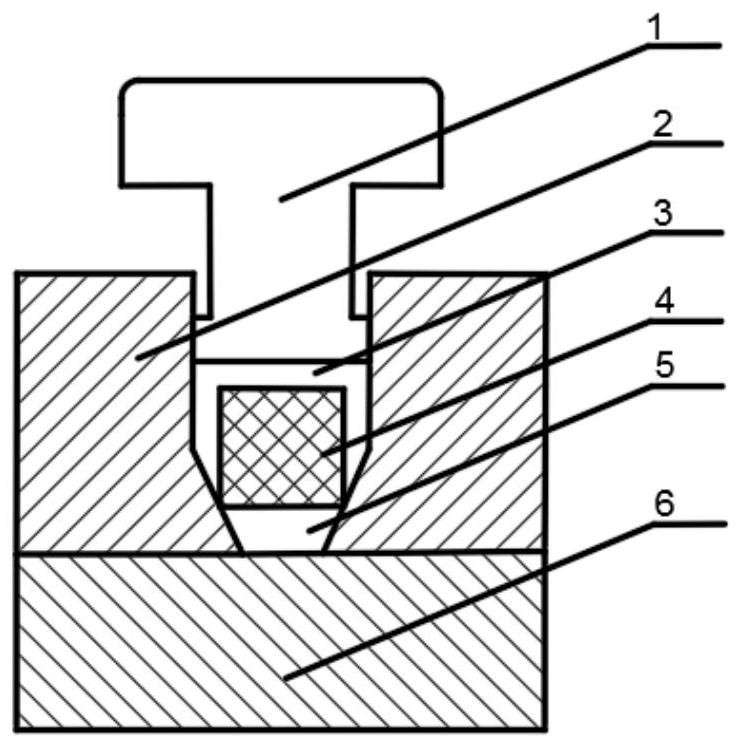

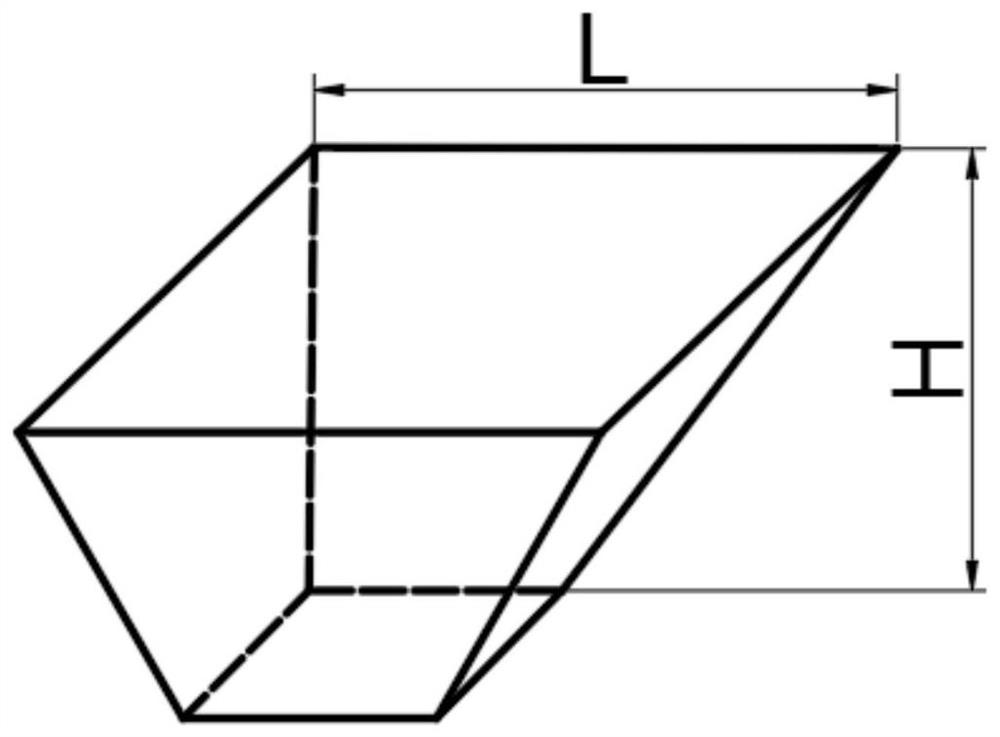

[0033]A multi-directional repeated extrusion and deformation processing device for magnesium alloy profiles includes a convex mold 1, an upper concave mold 2 and a lower concave mold 6. The upper concave mold 2 is provided with a mold cavity, and the mold cavity is formed by a convex mold. The channel 3 and the extrusion channel 5 are composed of the male die channel 3 in the shape of a rectangular parallelepiped, the extrusion channel 5 is in the shape of an inverted regular quadrangular pyramid, and the upper die 2 and the lower die 6 are connected and combined by screws and pins. The convex mold 1 is set in the convex mold channel 3 and cooperates with the convex mold channel 3; preferably, the length L of the bottom edge of the mold cavity quadrangular table is greater than or equal to the mold The height H of the quadrangular prism of the cavity, the four rims of the quadrangular prism are all set up obliquely, and have a 1mm round corner.

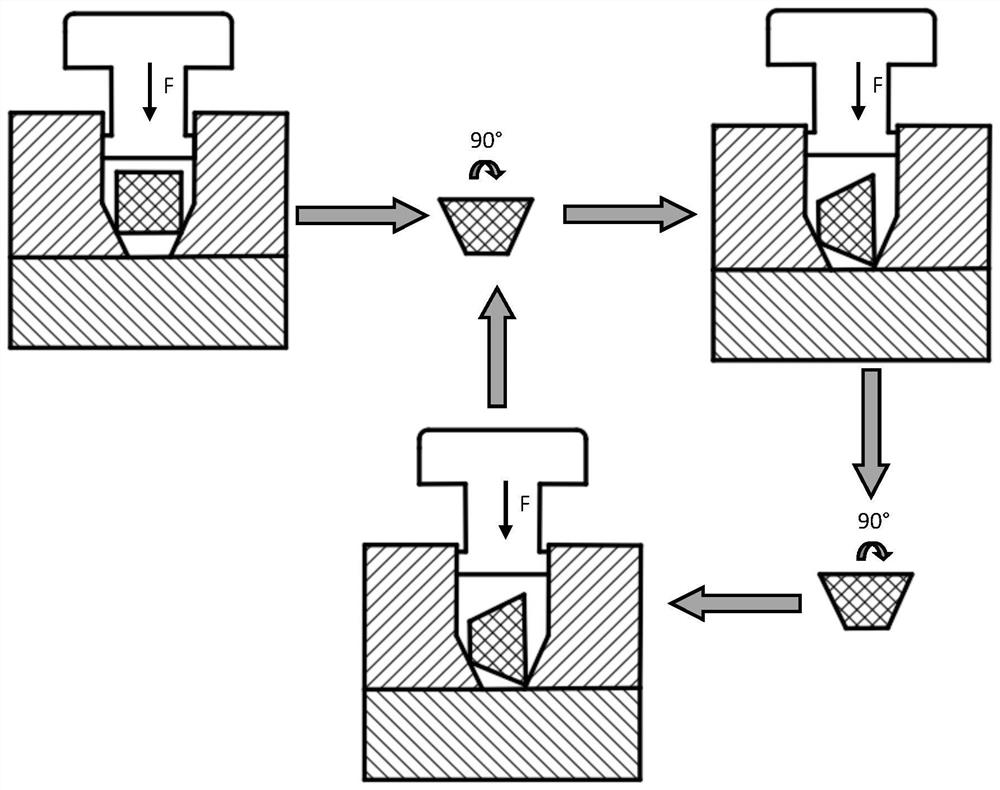

[0034]The method for multi-directional ...

Embodiment 2

[0047]A multi-directional repeated extrusion and deformation processing device for magnesium alloy profiles includes a convex mold 1, an upper concave mold 2 and a lower concave mold 6. The upper concave mold 2 is provided with a mold cavity, and the mold cavity is formed by a convex mold. The channel 3 and the extrusion channel 5 are composed of the male die channel 3 in the shape of a rectangular parallelepiped, the extrusion channel 5 is in the shape of an inverted regular quadrangular pyramid, and the upper die 2 and the lower die 6 are connected and combined by screws and pins. The convex mold 1 is set in the convex mold channel 3 and cooperates with the convex mold channel 3; preferably, the length L of the bottom edge of the mold cavity quadrangular table is greater than or equal to the mold The height H of the four-sided pedestal of the cavity, the four edges of the four-sided pedestal are set up obliquely, and have a rounded corner of 1.5mm.

[0048]The method for multi-direct...

Embodiment 3

[0061]A multi-directional repeated extrusion and deformation processing device for magnesium alloy profiles includes a convex mold 1, an upper concave mold 2 and a lower concave mold 6. The upper concave mold 2 is provided with a mold cavity, and the mold cavity is formed by a convex mold. The channel 3 and the extrusion channel 5 are composed of the male die channel 3 in the shape of a rectangular parallelepiped, the extrusion channel 5 is in the shape of an inverted regular quadrangular pyramid, and the upper die 2 and the lower die 6 are connected and combined by screws and pins. The convex mold 1 is set in the convex mold channel 3 and cooperates with the convex mold channel 3; preferably, the length L of the bottom edge of the mold cavity quadrangular table is greater than or equal to the mold The height H of the quadrangular prism of the cavity, the four rims of the quadrangular prism are all set up obliquely, and have a 2mm rounded corner.

[0062]The method for multi-directiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com