Robot equipment

A robot and equipment technology, applied in the direction of boring bars, etc., can solve the problems of easy tremor, difficult to control the vertical size and lateral positioning size of the inner wall of the pipe hole, poor roughness of the inner wall of the pipe hole, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

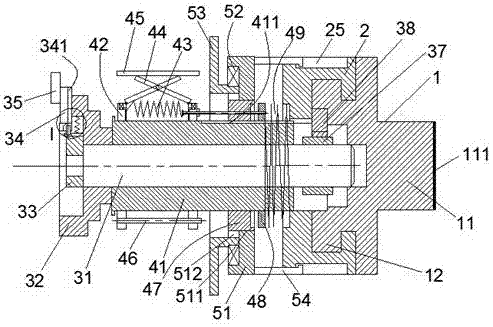

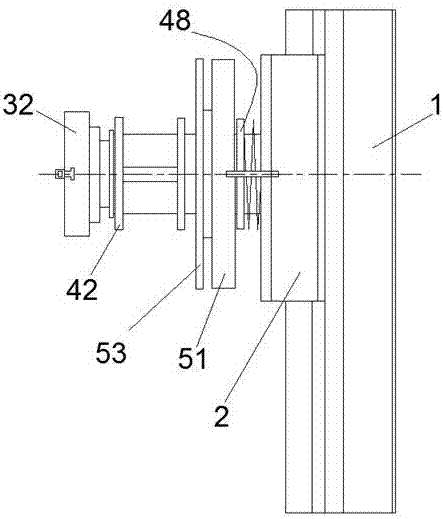

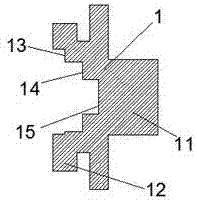

[0029] Such as Figure 1-Figure 8 As shown, a robot device of the present invention includes a clamping member 1, an end body 2, a vertical manipulation device, a horizontal manipulation device and a clamping device. The left side of the clamping member 1 is provided with a strip 11, and the upper and lower end surfaces on the right side Each is provided with a guide bar 12 in the front and rear directions, and a step group consisting of a first step 13, a second step 14 and a third step 15 is provided in the front and rear direction of the middle end of the right side, and the side of the strip 11 is also provided with The rubber pressing piece 111, the right side of the end body 2 is provided with a front and rear direction guide hole 21 that slides and fits with the guide bar 12, and is centered up and down with the guide hole 21 and close to the front end A first through groove 22 in the left and right direction is provided, a plate groove 24 for installing a position guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com