Preparation method and application of iodide ion doping modified fe-mof bulk electrode material

A technology of electrode materials and iodide ions, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low Coulombic efficiency, slow reaction rate, and limited energy density of Fe-MOF materials, etc., and achieve a fast reaction process , the process is reversible, and the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

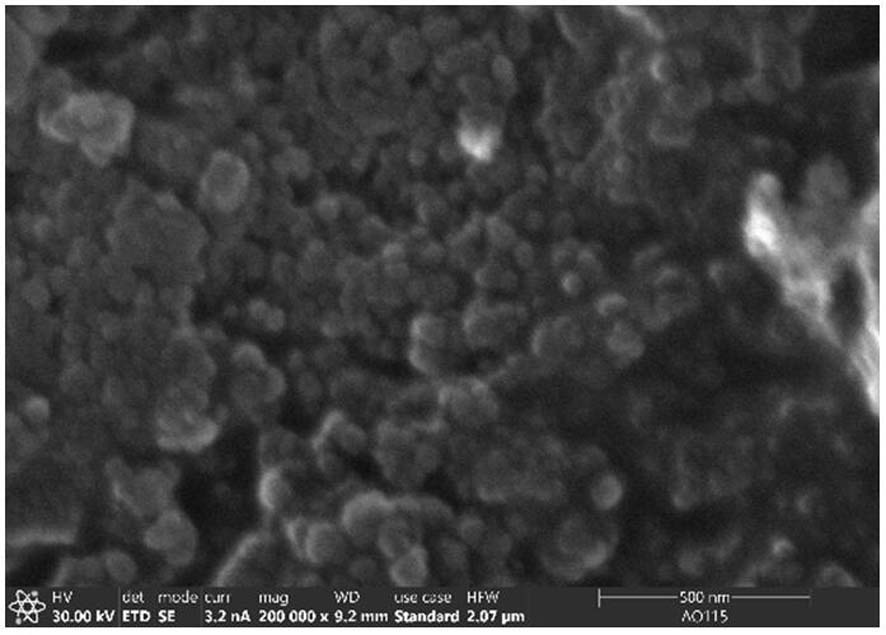

[0036] A preparation method of an iodide ion-doped modified Fe-MOF bulk electrode material, the specific steps are as follows:

[0037] (1) Weigh 1 mmol of ferric chloride and dissolve it in 10 mL of deionized water to form A solution, weigh 1 mmol of potassium ferrocyanide and dissolve it in 10 mL of deionized water to form B solution, and add 0.5 g polyethylene to the B solution. Pyrrolidone PVP templating agent, 1 mL sulfuric acid, 0.5 g trisodium citrate, wherein the relative molecular mass of polyvinylpyrrolidone PVP templating agent is 10000. The A and B solutions were stirred at room temperature for 5 minutes and then added to the hydrothermal tank for a hydrothermal reaction, wherein the mol ratio of the iron salt in the A solution to the potassium ferrocyanide in the B solution was 0.75:0.75; the hydrothermal reaction temperature was 60°C, and the reaction The time was 24 h; the products obtained from the reaction were collected and centrifuged for 3 times with a mixt...

Embodiment 2

[0042] A preparation method of an iodide ion-doped modified Fe-MOF bulk electrode material, the specific steps are as follows:

[0043] (1) Weigh 1 mmol of ferric sulfate and dissolve it in 10 mL of deionized water to generate solution A. Weigh 1 mmol of potassium ferrocyanide and dissolve it in 10 mL of deionized water to generate solution B. A and B solutions are stirred at room temperature for 60 minutes and then added In the inner tank of the hydrothermal kettle, the water is heated for 24 hours, and the temperature of the hydrothermal reaction is 60 °C. The molar ratio of ferric salt in solution A to potassium ferrocyanide in solution B is 0.75:0.75; the product obtained from the reaction is collected, and centrifuged for 4 times with a mixture of ethanol and deionized water, and finally a blue product is obtained, which is Fe-MOF block shape electrode material.

[0044] (2) Grind the Fe-MOF electrode material in step (1) for 5 minutes, put it into a plasma etching machi...

Embodiment 3

[0047] A preparation method of an iodide ion-doped modified Fe-MOF bulk electrode material, the specific steps are as follows:

[0048] (1) Weigh 1 mmol of ferric nitrate and dissolve it in 10 mL of deionized water to generate solution A, weigh 1 mmol of potassium ferrocyanide and dissolve it in 10 mL of deionized water to generate solution B, and add 0.5 g of polyvinylpyrrolidone to solution B PVP template agent, 1 mL of sulfuric acid, 0.1 g of trisodium citrate, wherein the relative molecular mass of the polyvinylpyrrolidone PVP template agent is 1,300,000. The A and B solutions were stirred at room temperature for 5 minutes and then added to the hydrothermal tank for hydrothermal reaction, wherein the molar ratio of the iron salt in the A solution to the potassium ferrocyanide in the B solution was 0.75:2; the hydrothermal reaction temperature was 120 ° C, and the reaction The time was 12h; the products obtained from the reaction were collected and centrifuged for 5 times w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com