Preparation method and antibacterial application of camphor tree essential oil

A technology of camphor tree and essential oil, applied in the field of separation and application, and vegetable oil extraction, can solve the problems affecting the chemical composition of the extract and the effect of application, and achieve the effects of easy scale-up production, simple operation process, and improved extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

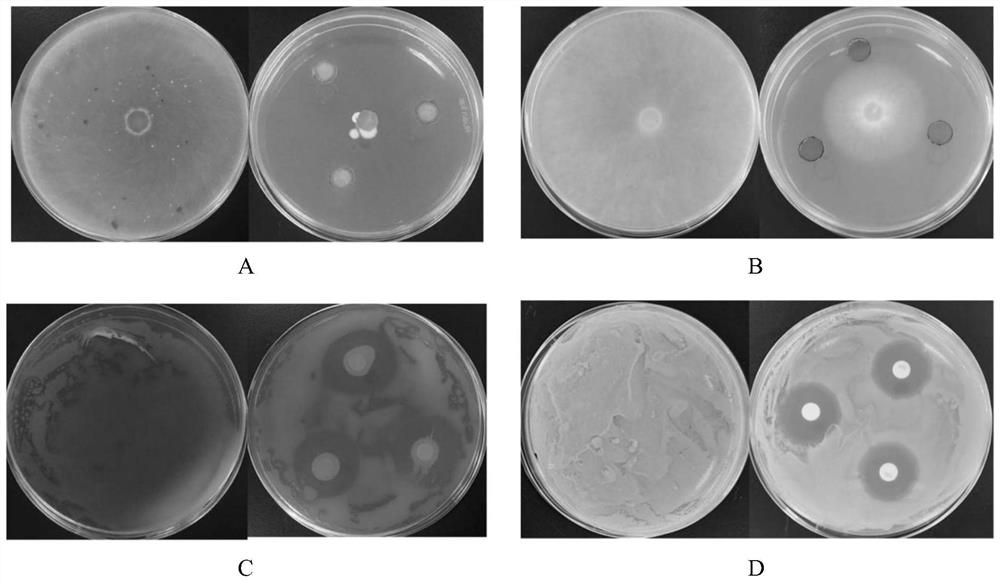

Image

Examples

Embodiment 2

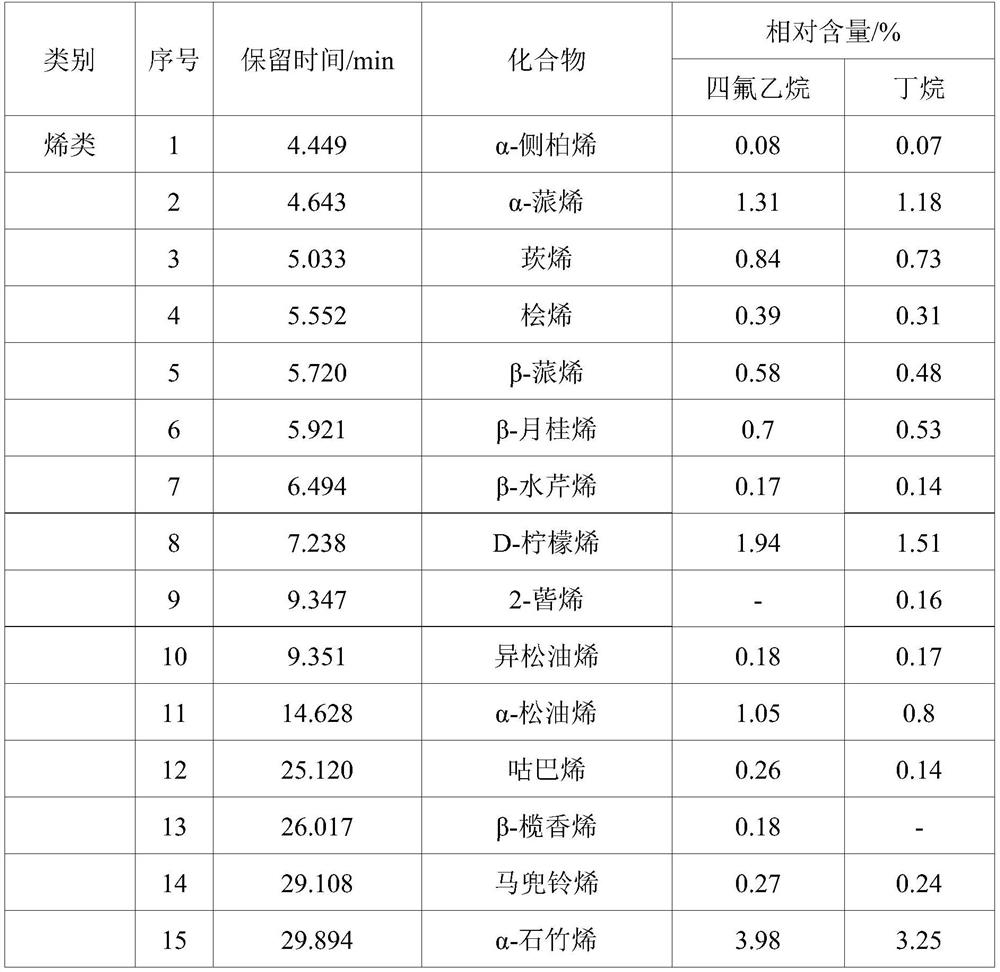

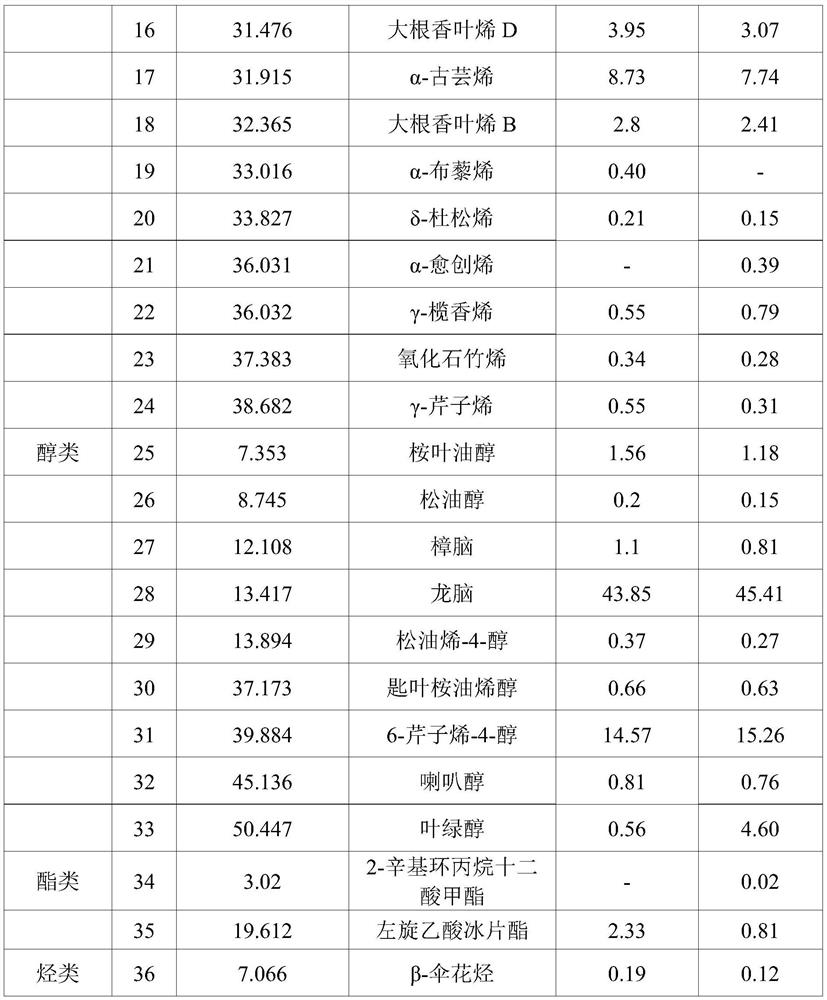

[0026] The preparation of embodiment 2 camphor tree essential oil

[0027] The fresh camphor branches and leaves are dried at 55° C. for 5 hours with a heat pump dryer to a moisture content of 4%, and the dried camphor branches and leaves are pulverized through a 20-mesh sieve by a pulverizer to obtain camphor branch and leaf powder.

[0028] Put the camphor tree leaf powder into a 300-mesh filter bag and place it in the extraction tank of the subcritical extraction equipment. Use a vacuum pump to bring the system pressure to 0.01MPa, and then introduce tetrafluoroethane from the solvent tank into the extraction tank. During the period, a metering tank is used. The ratio of material to liquid is controlled to be 1:5 (mass to volume ratio kg / L), and then the extraction tank is heated to 45°C by a hot water circulation system, and the extraction time is controlled to 40min. With tetrafluoroethane, the extraction was repeated 4 times, and the extracts were combined to obtain crud...

Embodiment 3

[0030] The preparation of embodiment 3 camphor tree essential oil

[0031] Dry the fresh camphor branches and leaves at 50° C. for 6 hours with a heat pump dryer to a moisture content of 5%, and use a pulverizer to pulverize the dried camphor branches and leaves to 40 mesh.

[0032] Put the camphor tree leaf powder into a 300-mesh filter bag and place it in the extraction tank of the subcritical extraction equipment. Use a vacuum pump to bring the system pressure to 0.01MPa, and then introduce tetrafluoroethane from the solvent tank into the extraction tank. During the period, a metering tank is used. The ratio of material to liquid is controlled to be 1:6 (mass to volume ratio kg / L), and then the extraction tank is heated to 45°C by a hot water circulation system, and the extraction time is controlled to 50min. With tetrafluoroethane, the extraction was repeated 4 times, and the extracts were combined to obtain crude camphor tree oil.

[0033] Add 20 times (mass volume ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com