Sand bin with cooling function for lost foam casting

A technology of lost foam casting and sand storage, which is used in manufacturing tools, casting molding equipment, and machinery for cleaning/processing mold materials. It can solve the problems of uneven cooling, single cooling method, and low cooling efficiency, and improve the Effects of cooling efficiency, reduced contamination, improved uniformity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

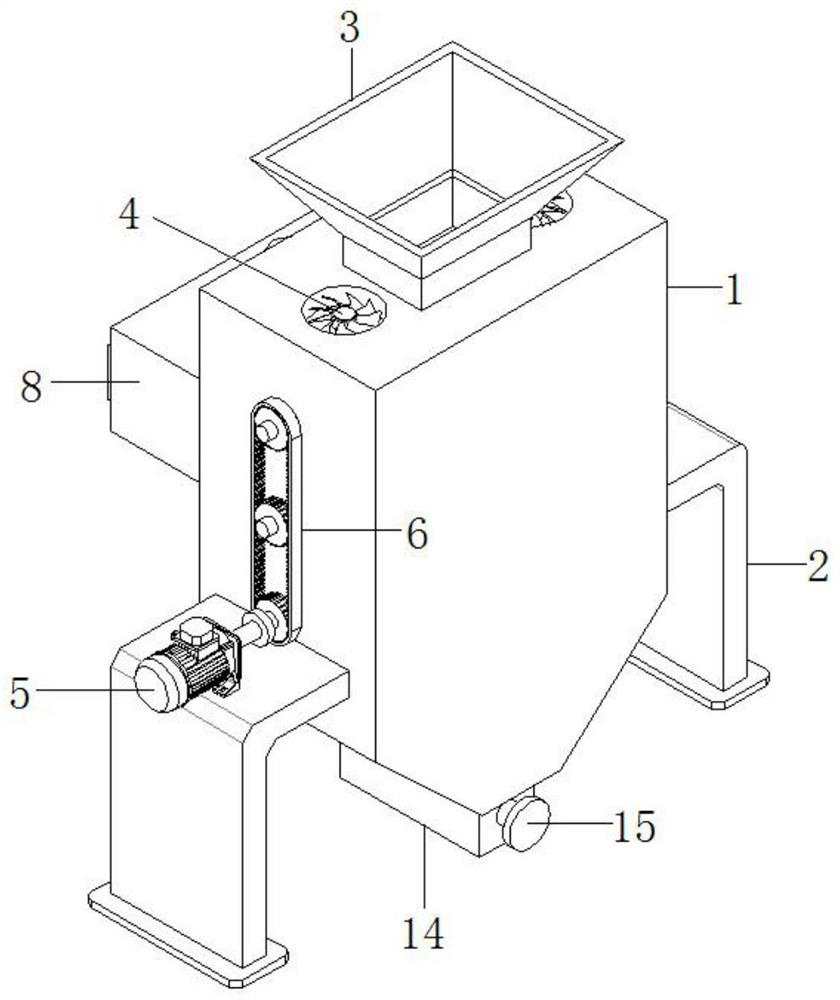

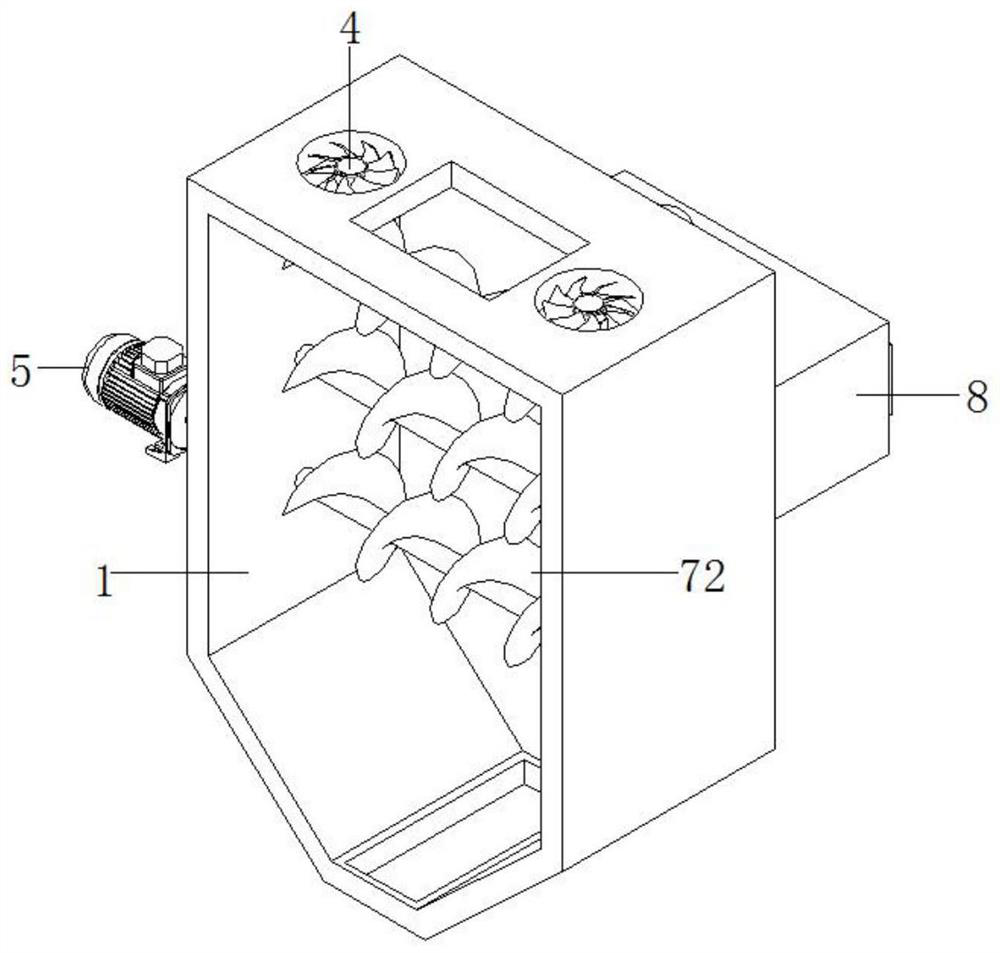

[0022] Example 1, refer to Figure 1-3 , a sand storehouse with cooling function for lost foam casting, which consists of a sand storehouse body 1, a heat absorption mechanism, a feeding hopper 3, two cooling fans 4 and a stirring mechanism;

[0023] The lower outer walls of the two sides of the sand storehouse body 1 are welded with support frames 2 for support. The two support frames 2 are both L-shaped and symmetrically arranged. The bottom outer walls of the two support frames 2 are also bonded with anti-skid pads. The feeding hopper 3 is fixedly connected to the top of the sand storage body 1, the two cooling fans 4 are also fixedly connected to the top of the sand storage body 1, and the bottom of the sand storage body 1 is fixedly connected with a discharge square pipe 14, and the discharge square pipe 14 A discharge valve 15 is installed on the upper wafer;

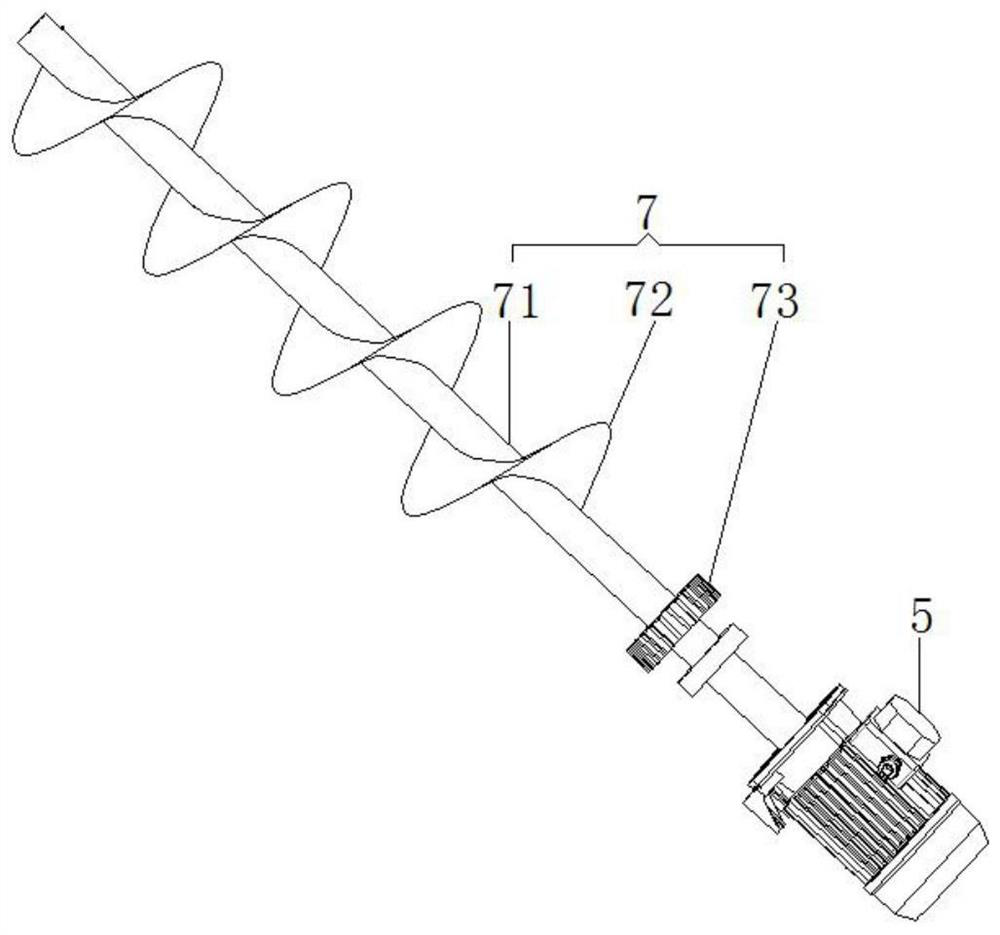

[0024] The stirring mechanism is specifically composed of the motor 5 fixed on the top outer wall of one of th...

Embodiment 2

[0027] Example 2, refer to figure 1 and Figure 4 , this embodiment is optimized on the basis of Embodiment 1, specifically:

[0028] The heat absorption mechanism is specifically composed of a box body 8 welded on the back outer wall of the sand storehouse body 1, a heat absorption fan 9 fixedly connected to the bottom of the box body 8, a drawer 10 movably installed in the box body 8, and a fixed connection to the bottom of the drawer 10. It is composed of a dustproof net 11, the box body 8 is communicated with the sand storage body 1 through a heat extraction pipe 12, and a material blocking net 13 is fixedly installed on the heat extraction pipe 12, and the material blocking net 13 can prevent the material from being sucked out by the heat-absorbing fan 9;

[0029] In this embodiment, part of the heat is extracted and cooled by the heat absorption mechanism, and the cooling is combined with the cold air blown by the two cooling fans 4, so that the cooling methods of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com