High-forming baking-resistant 5xxx series aluminum alloy plate and preparation method thereof

A kind of aluminum alloy sheet material, baking-resistant technology, applied in the direction of metal rolling, process efficiency improvement, coating, etc., can solve the problems that are difficult to balance formability, baking resistance and mechanical properties, and achieve significant baking hardening Ability, improve work hardening ability, avoid softening or insufficient mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

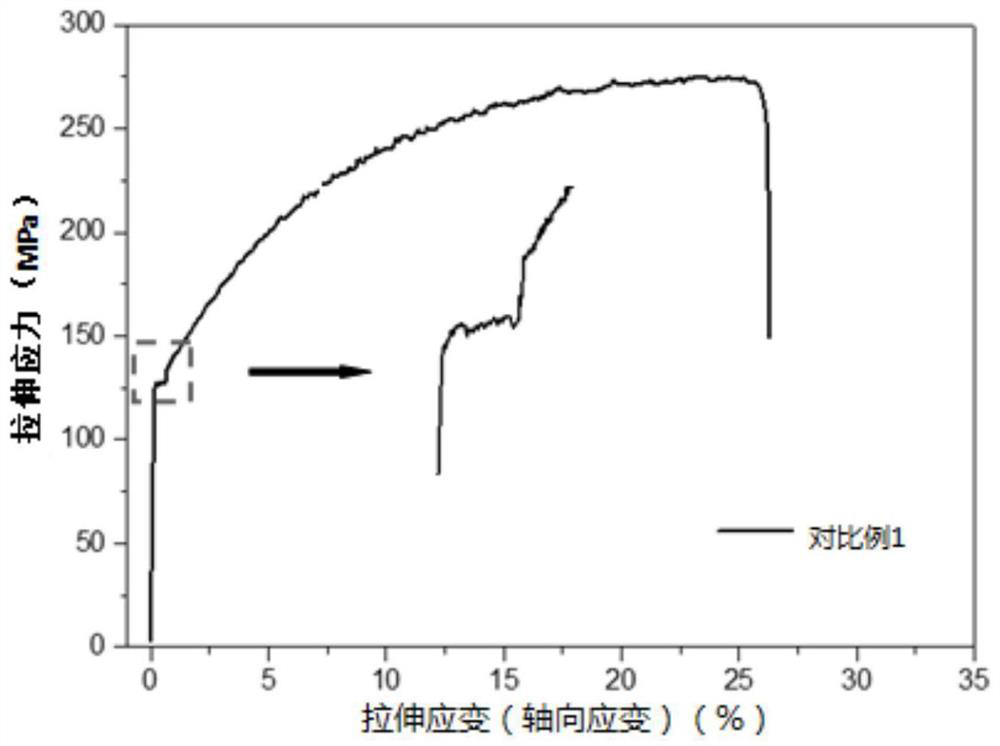

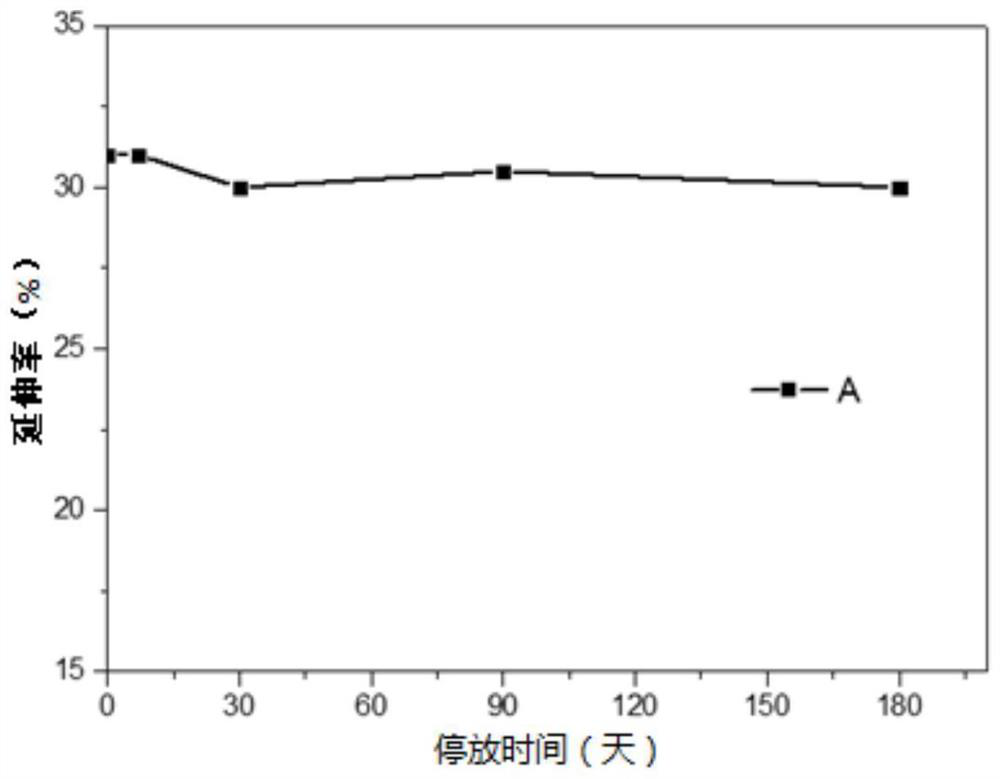

[0039] As described in the background of the present invention, there is a problem in the prior art that 5xxx series aluminum alloys are difficult to take into account formability, baking resistance and mechanical properties. In order to solve the above problems, in a typical embodiment of the present invention, there is provided a method for preparing a 5xxx series aluminum alloy sheet with high forming and baking resistance, including the following steps: step S1, mixing raw materials of 5xxx series aluminum alloy and mixing Melting and casting the ingot to obtain an aluminum alloy ingot; wherein, by weight percentage, the aluminum alloy composition is: Mg 5.0-7.5wt.%, Cu 0.15-0.6wt.%, Si≤0.1wt.%, Fe 0.1-0.4wt% %, Mn 0.05~0.15wt.%, Cr≤0.05wt.%, Ti≤0.1wt.%, the sum of inevitable impurities≤0.15wt.%, the balance is Al; step S2, the aluminum alloy ingot is carried out Double-stage homogenization treatment. In the double-stage homogenization treatment, the temperature is first r...

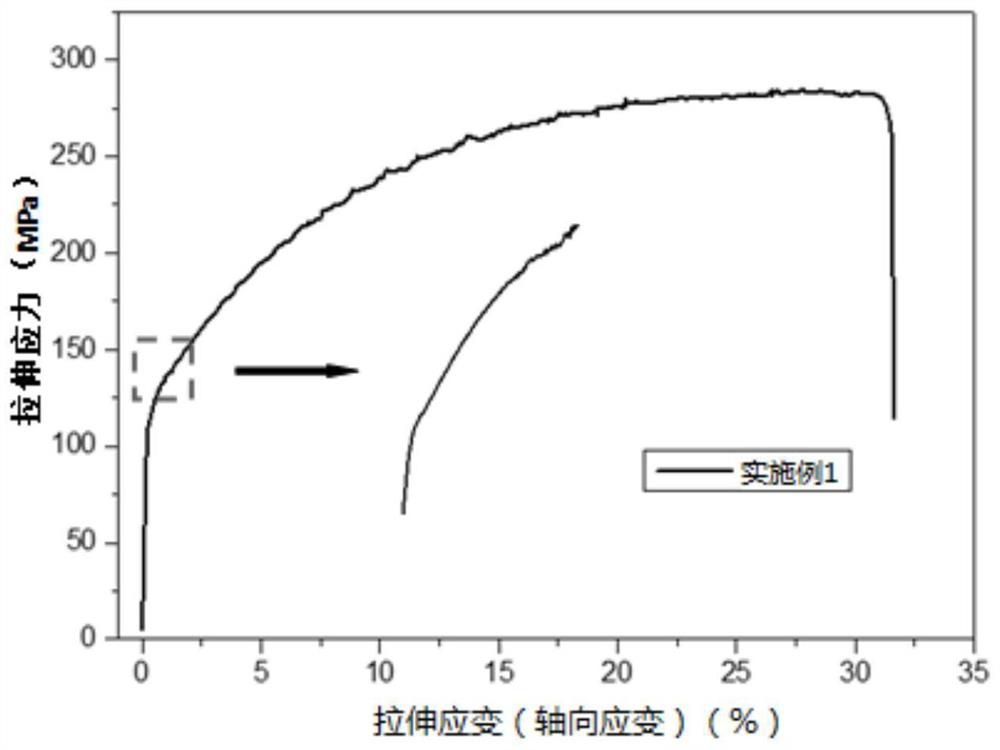

Embodiment 1

[0056] The aluminum alloy composition in mass percentage is: Mg 6.0wt.%, Cu 0.3wt.%, Si 0.08wt.%, Fe0.12wt.%, Mn 0.05wt.%, Cr 0.01wt.%, Ti 0.05wt.% , and the rest are Al.

[0057] The above alloy components are cast into slabs by semi-continuous casting. The ingot is homogenized by a two-stage homogenization process. First, the temperature is raised to 440°C at 30°C / h, and kept for 2 hours, and then heated to 500°C at 30°C / h, kept for 10 hours, and then taken out for air cooling. The ingot after milling was heated to 500°C for 3 hours for hot rolling, and the final rolling temperature was 300°C. Cold-rolling and intermediate annealing are performed on the plate, and box-type annealing is used for intermediate annealing, the temperature is 280° C., and the temperature is kept for 3 hours. Then, the plate after intermediate annealing is cold-rolled, and the cold rolling reduction rate is 50%. The cold-rolled sheet is continuously annealed, the annealing temperature is 530°C, a...

Embodiment 2

[0059] The aluminum alloy composition in mass percentage is: Mg 7.1wt.%, Cu 0.15wt.%, Si 0.08wt.%, Fe0.10wt.%, Mn 0.12wt.%, Cr 0.01wt.%, Ti 0.10wt.% , and the rest are Al.

[0060] The above alloy components are cast into slabs by semi-continuous casting. The ingots were homogenized using a two-stage homogenization process. First, the temperature was raised to 440°C at 30°C / h, and kept for 4 hours, and then heated to 540°C at 25°C / h, kept for 8 hours, and then taken out for air cooling. The ingot after milling was heated to 500°C for 3 hours for hot rolling, and the final rolling temperature was 330°C. Cold rolling and intermediate annealing are carried out on the plate, and the intermediate annealing adopts box annealing, the temperature is 350° C., and the temperature is kept for 3 hours, and then the plate after intermediate annealing is cold-rolled, and the cold rolling reduction rate is 50%. The cold-rolled sheet is continuously annealed, the annealing temperature is 54...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com