Oil-resistant anti-corrosion PVC (polyvinyl chloride) cable material and preparation method thereof

An anti-corrosion and cable material technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of easy short circuit leakage, fire, easy aging, etc., and achieve good aging resistance, low production cost, and good oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

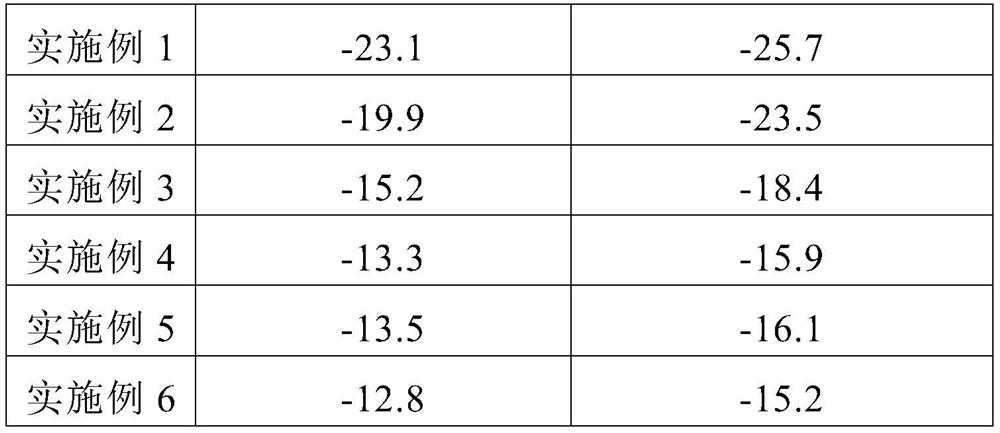

Embodiment 1

[0047] An oil-resistant and anti-corrosion PVC cable material is composed of the following raw materials in parts by weight:

[0048] 85 parts by weight of PVC resin, 26 parts by weight of nitrile rubber, 3 parts by weight of butyl stearate, 2 parts by weight of lanthanum cyanurate, 44 parts by weight of plasticizer, 5 parts by weight of tris(2-chloroethyl) phosphate , 35 parts by weight filler.

[0049] The plasticizer is acetyl tributyl citrate.

[0050] The filler is calcined clay.

[0051] The nitrile rubber is solid nitrile rubber.

[0052] The preparation method of the solid nitrile rubber is as follows: the nitrile latex is added to a 20wt% calcium chloride aqueous solution, stirred for 20 min at a rotating speed of 1500 rpm, and the precipitate is taken out and freeze-dried to obtain the solid nitrile rubber; wherein the nitrile latex and The mass ratio of the 20wt% calcium chloride aqueous solution is 10:3.

[0053] The preparation method of the oil-resistant and ...

Embodiment 2

[0058] An oil-resistant and anti-corrosion PVC cable material is composed of the following raw materials in parts by weight:

[0059] 85 parts by weight of PVC resin, 26 parts by weight of nitrile rubber, 3 parts by weight of butyl stearate, 2 parts by weight of lanthanum cyanurate, 44 parts by weight of plasticizer, 5 parts by weight of tris(2-chloroethyl) phosphate , 35 parts by weight filler.

[0060] The plasticizer is acetyl tributyl citrate.

[0061] The filler is calcined clay.

[0062] The nitrile rubber is modified nitrile rubber.

[0063] The preparation method of the modified nitrile rubber is as follows:

[0064] 28 parts by weight of nitrile latex was added to 200 parts by weight of dichloromethane, stirred at 800 rpm and condensed and refluxed at 40°C for 3 hours, and then added 50 parts by weight of absolute ethanol, 7 parts by weight of hydroxylamine hydrochloride and 20 parts by weight of 50 parts by weight of anhydrous ethanol, 7 parts by weight of hydrox...

Embodiment 3

[0070] An oil-resistant and anti-corrosion PVC cable material is composed of the following raw materials in parts by weight:

[0071] 85 parts by weight of PVC resin, 26 parts by weight of nitrile rubber, 3 parts by weight of butyl stearate, 2 parts by weight of lanthanum cyanurate, 44 parts by weight of plasticizer, 5 parts by weight of tris(2-chloroethyl) phosphate , 35 parts by weight filler.

[0072] The plasticizer is acetyl tributyl citrate.

[0073] The filler is calcined clay.

[0074] The nitrile rubber is graft-modified nitrile rubber.

[0075] The preparation method of described graft-modified nitrile rubber is as follows:

[0076] S1, adding 28 parts by weight of nitrile latex to 200 parts by weight of methylene chloride, stirring at a rotating speed of 800 rpm and condensing and refluxing at 40 ° C for 3h, then adding 50 parts by weight of absolute ethanol, 7 parts by weight of hydroxylamine hydrochloride and 20 parts by weight of sodium carbonate, continue to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com