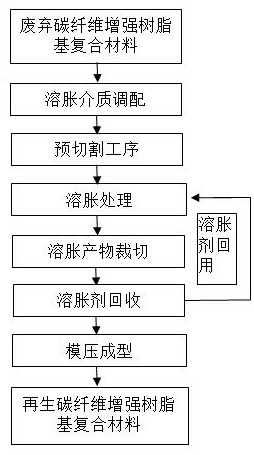

Swelling dissociation recovery method for waste carbon fiber reinforced resin-based composite material

A technology for reinforcing resin-based and composite materials, which is applied in the fields of plastic recycling and recycling technology, which can solve the problems of swelling softening, high delamination and dissociation temperature, and high degradation rate of epoxy resin, and achieve mild swelling, dissociation and recycling reaction conditions , the effect of avoiding environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dimethylacetamide and 1,3-dimethyl-2-imidazolinone were made into a thermosetting epoxy resin swelling agent according to the volume ratio of 90:10; the whole or cut large piece CFRP was immersed in the swelling agent, and the swelling reactor was sealed for swelling treatment, the swelling reaction temperature was 160 °C, the treatment time was 1 h, and the liquid-to-liquid ratio was 40:1. CFRP is removed from the swelling agent and drained of the swelling agent attached to the surface of the CFRP, at which time the CFRP is delaminated and the resin degradation rate is 0.70%. The layered carbon fiber composite is cut into uniformly shaped rectangular sheets (20 mm wide, 80 mm long, 0.2 mm thick). The swelling agent contained in the CFRP cutting product is recovered by drying or vacuum distillation; a certain amount of liquid epoxy resin is added to the dried CFRP cutting product, and the carbon fiber reinforced resin matrix composite material of different shapes and thickn...

Embodiment 2

[0024]Dimethylacetamide and 1,3-dimethyl-2-imidazolinone are made into a thermosetting epoxy resin swelling agent according to the volume ratio of 98:2; the whole or cut large piece CFRP is immersed in the swelling agent, and the swelling reactor is sealed for swelling treatment, the swelling reaction temperature is 100 °C, the treatment time is 1 h, and the liquid-solid ratio is 20:1. CFRP is removed from the swelling agent and drained of the swelling agent attached to the surface of the CFRP, at which time the CFRP undergoes swelling and softening, but it is not delaminated, and the resin degradation rate does not exceed 0.1%. The swelling softening product is cut into thin strips 100 mm long, 2 mm wide and 2 mm thick. The swelling agent contained in the CFRP cutting product is recovered by drying or reduced pressure distillation; a certain amount of liquid epoxy resin is added to the dried CFRP cutting product, and the carbon fiber reinforced resin matrix composite material of ...

Embodiment 3

[0026] Dimethylacetamide and 1,3-dimethyl-2-imidazolinone were made into a thermosetting epoxy resin swelling agent according to the volume ratio of 95:5; the whole or cut large piece CFRP was immersed in the swelling agent, and the swelling reactor was sealed for swelling treatment, the swelling reaction temperature was 140 °C, the treatment time was 1 h, and the liquid-solid ratio was 30:1. CFRP is removed from the swelling agent and drained of the swelling agent attached to the surface of the CFRP, at which time the CFRP is delaminated and the resin degradation rate does not exceed 0.2%. The layered carbon fiber composite is cut into square sheets (100 mm long, 100 mm wide, 0.2 mm thick). The swelling agent contained in the CFRP cutting product is recovered by drying or vacuum distillation; after coating the surface of the cut square carbon fiber composite material with epoxy resin, the multi-layer carbon fiber sheets are neatly stacked together, and the square carbon fiber boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com