Nano aluminum oxide diaphragm coating and preparation method thereof

A nano-alumina, aluminum oxide technology, applied in the direction of separator/film/diaphragm/spacer, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of lithium-ion battery capacity, cycle performance, safety performance, impact Lithium-ion battery diaphragm quality, aluminum oxide slurry is easy to precipitate and other problems, to achieve good coating construction performance, improve suspension stability, and ensure the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

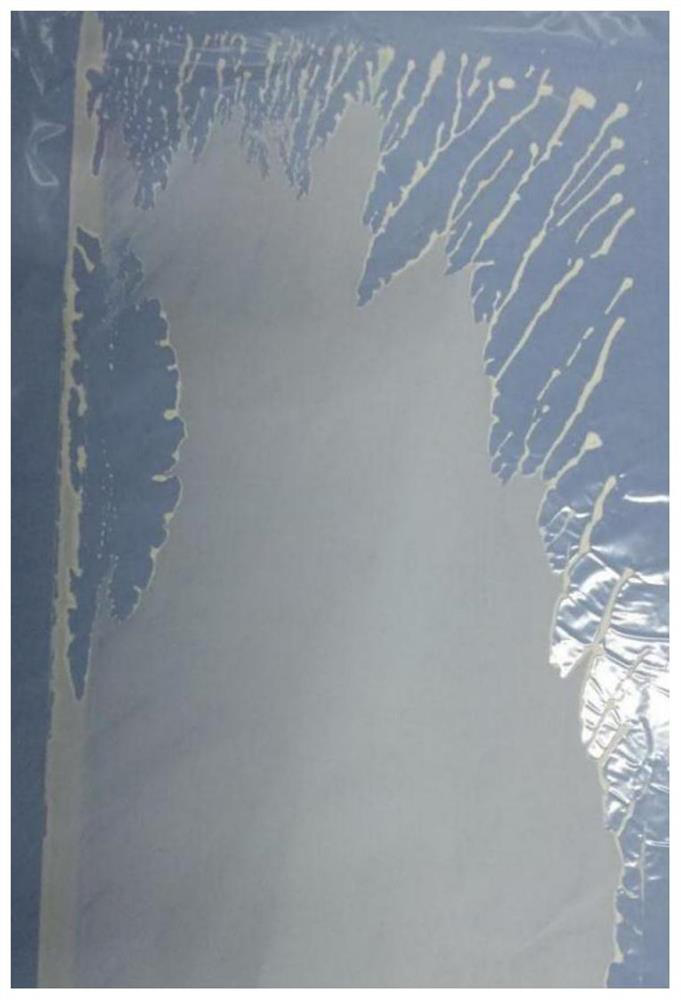

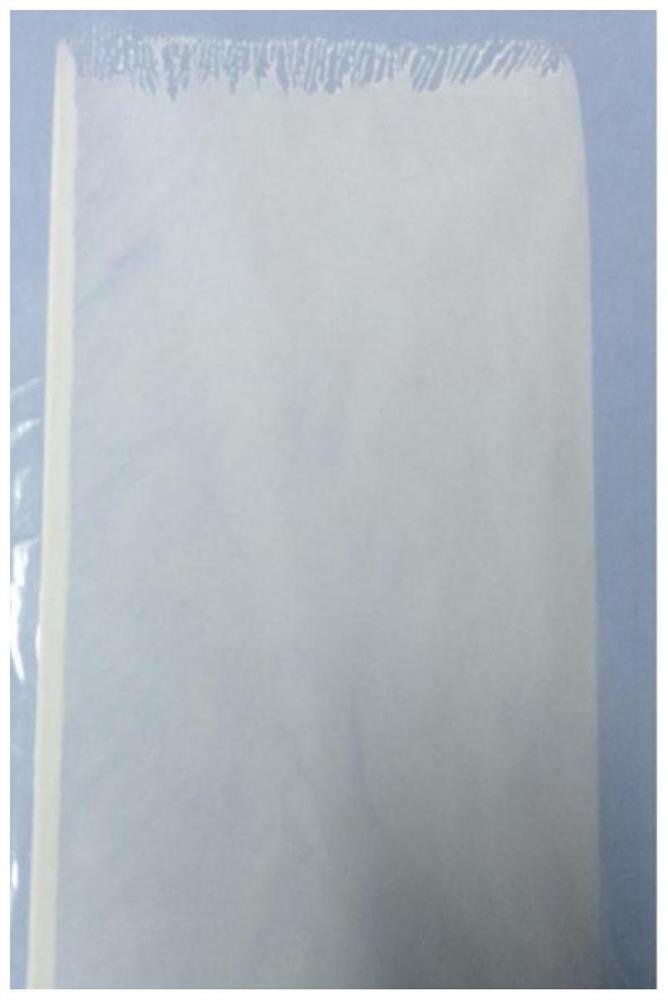

Image

Examples

Embodiment 1

[0088] This embodiment provides a nano-alumina separator paint for coating the surface of a lithium-ion battery separator.

[0089] A kind of nano-alumina diaphragm coating that present embodiment provides comprises:

[0090] Nano-alumina particles, acrylic polymer particles, carboxymethyl cellulose, polyoxyethylene lauryl ether and pure water, of which:

[0091] The nano-alumina diaphragm coating has a solid content of 38% to 42% (mass percentage), a viscosity of 100 to 300mPa.s, and a pH of 8 to 9; and

[0092] The particle size distribution of nano-alumina particles in the nano-alumina diaphragm coating is: D50 is between 0.4 and 0.8 μm and D90 is not greater than 2.5 μm.

[0093] From the above description, it can be seen that:

[0094] First of all, in this embodiment, nano-alumina particles with characteristics of insulation, heat insulation, flame retardancy, high temperature resistance, and self-shutoff are selected as the aggregate of nano-alumina diaphragm coating ...

Embodiment 2

[0114] This embodiment provides a preparation method of the nano-alumina diaphragm coating described in the above-mentioned embodiment 1.

[0115] A preparation method of nano-alumina diaphragm coating, comprising the steps of:

[0116] Mix nano-alumina particles with pure water and grind them into nano-alumina slurry;

[0117] Carboxymethyl cellulose and pure water are stirred and mixed to make carboxymethyl cellulose slurry;

[0118] mixing and stirring the nano-alumina slurry and the carboxymethyl cellulose slurry; or

[0119] Mixing the nano-alumina slurry and the carboxymethyl cellulose slurry, adding a dispersant and stirring to prepare an alumina-cellulose mixed solution;

[0120] Adding acrylic polymer particles to the alumina cellulose mixture and stirring to prepare the alumina cellulose polymer mixture;

[0121] Adding polyoxyethylene lauryl ether into the alumina cellulose polymer mixture and stirring and mixing to prepare the alumina cellulose polymer alkyl eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com