Manufacturing method for small-spacing mask of outdoor LED display screen

A technology of an LED display screen and a manufacturing method, which is applied in the field of LED display screen and can solve the problems of local thickness difference and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

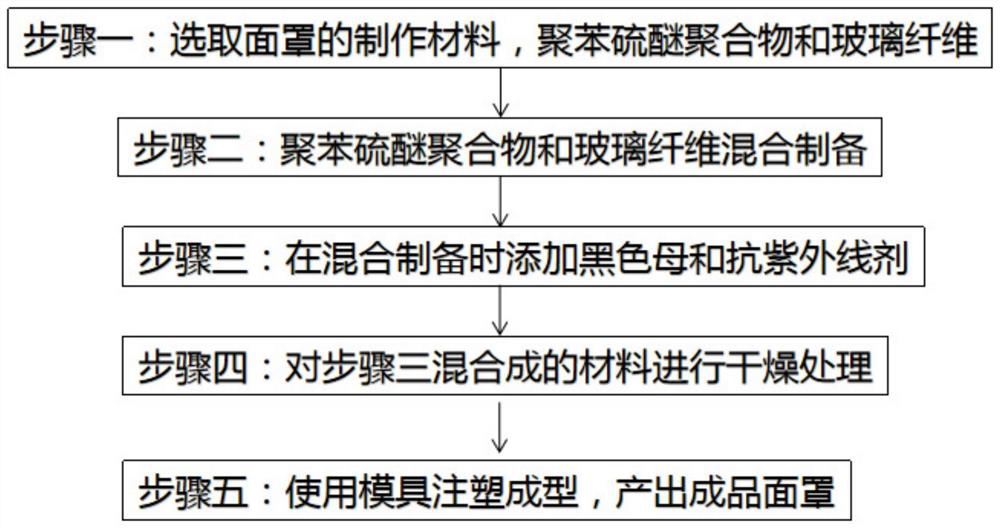

[0023] Please refer to figure 1 , the present invention proposes a manufacturing method of an outdoor LED display small-pitch mask comprising:

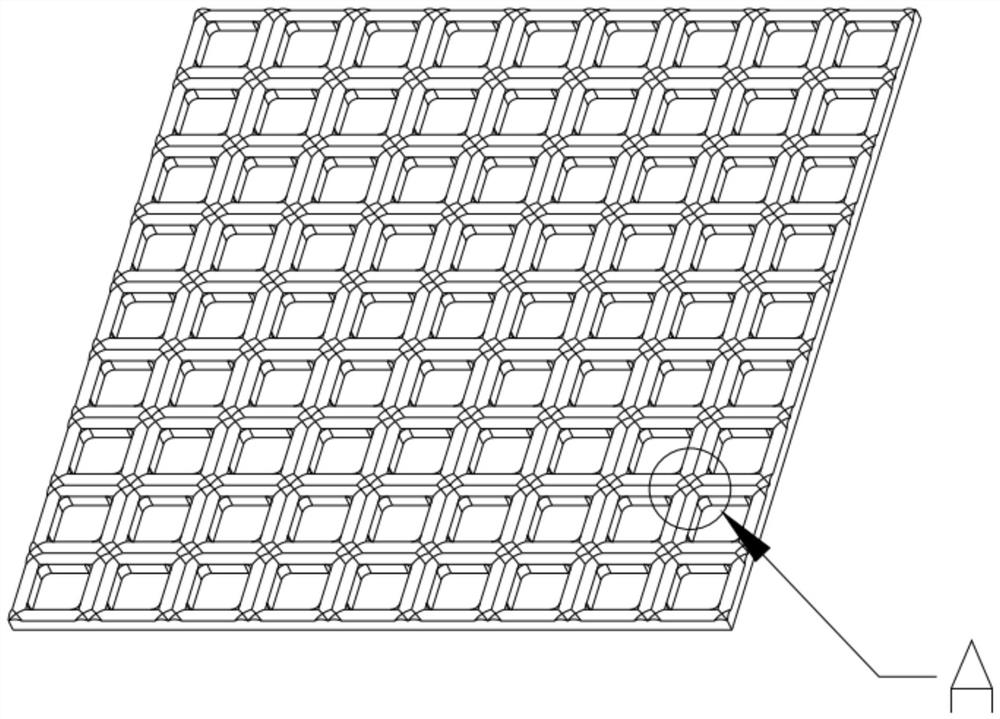

[0024] Step 1. Select the basic material for the mask, use polyphenylene sulfide polymer with a total base material ratio of 70%-80%, and use glass fiber with a total base material ratio of 20%-30%; Step 2. Use the base material The polyphenylene sulfide polymer and glass fiber are mixed and prepared, and the ratio is between 8:2 and 7:3; step 3, when the polyphenylene sulfide polymer and glass fiber are mixed and prepared, add 0.2-0.5 of the total amount of base materials % black masterbatch, add 0.25% anti-ultraviolet agent of the total amount of the base material; step 4, dry the mixed material in step 3, and bake it at 120-14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com