Ethylene polymer and preparation method thereof

A technology for ethylene polymers and polymers, which is applied in the field of high-density ethylene polymers and ethylene slurry polymerization preparations. It can solve the problems of unsuitable heat removal methods, high solvent content in polymer powders, and large consumption of catalysts, etc., to achieve Adjustable and controllable molecular weight distribution, excellent follow-up processing performance, and good follow-up processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

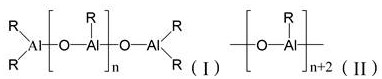

[0032] The present invention also provides a method for preparing ethylene polymers, wherein an alkane solvent with a boiling point of 5-55° C. or a mixed alkane solvent with a saturated vapor pressure of 20-150 KPa at 20° C. is used as a polymerization solvent, in the presence of a polyethylene catalyst system , when the molar ratio of hydrogen to ethylene is 0.01-20:1, preferably 0.015-10:1, the molar ratio of hydrogen to comonomer is 8-30:1, preferably 10-25:1, more preferably 12-23 : Under the condition of 1, the raw material comprising ethylene and comonomer is subjected to tank type slurry polymerization, and the polyethylene catalyst system comprises a polyethylene main catalyst of a Ziegler type catalyst.

[0033] In one embodiment of the present invention, in the preparation method of the ethylene polymer, the ratio of the polyethylene main catalyst to the polymerization solvent is 0.001-0.500 mmol polyethylene main catalyst / L polymerization solvent, preferably 0.005-0...

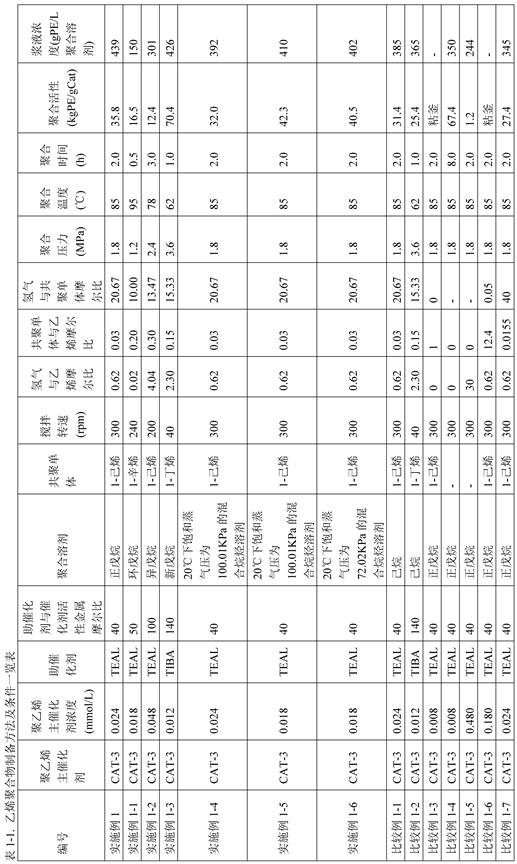

Embodiment 1

[0158] Ziegler-Natta catalyst CAT-3 (concentration 0.024mmol / L) was used as polyethylene main catalyst, co-catalyst was triethylaluminum (TEAL) in pentane solution (concentration 1.0mol / L), and the polymerization pressure was 1.8MPa, the polymerization temperature is 85°C, the polymerization solvent is n-pentane (boiling point 36.1°C), the dosage is 2.5L, and the comonomer is 1-hexene.

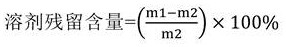

[0159] In the 5L anchor type ethylene slurry polymerization kettle with stirring, at first, 2.5L polymerization solvent is added in the polymerization autoclave at normal temperature, the stirring is started, and the rotation speed is 300rpm, then the polyethylene catalyst and co-catalyst mixture are added at one time, and Add comonomer at one time, then add hydrogen, and finally continue to feed ethylene to keep the polymerization pressure and polymerization temperature constant. After continuous reaction for 2 hours, vent the gas in the kettle to release the polymer in the kettle. Weigh the m...

Embodiment 1-1

[0161] Basically the same as Example 1, but with the following changes:

[0162] The main catalyst concentration of polyethylene is changed to 0.018mmol / L, the cocatalyst is a cyclopentane solution of triethylaluminum (concentration is 1.0mol / L), the polymerization pressure is 1.2MPa, the polymerization temperature is 95°C, and the polymerization solvent is cyclopentane Alkane (boiling point 49.26°C), the dosage is 2.5L, the comonomer is 1-octene, the rotation speed is 240rpm, the polymerization time is 0.5h, the ethylene polymer is marked as PE-1-1, the preparation process and conditions of the ethylene polymer As shown in Table 1-1, the properties of ethylene polymers are shown in Table 1-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com