Fiber-reinforced resin-based composite core overhead insulated cable

A fiber reinforced resin, overhead insulated cable technology, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve the problems of poor fireproof effect of cables, and achieve the effects of improving fireproofing effect, promoting spraying, and improving sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

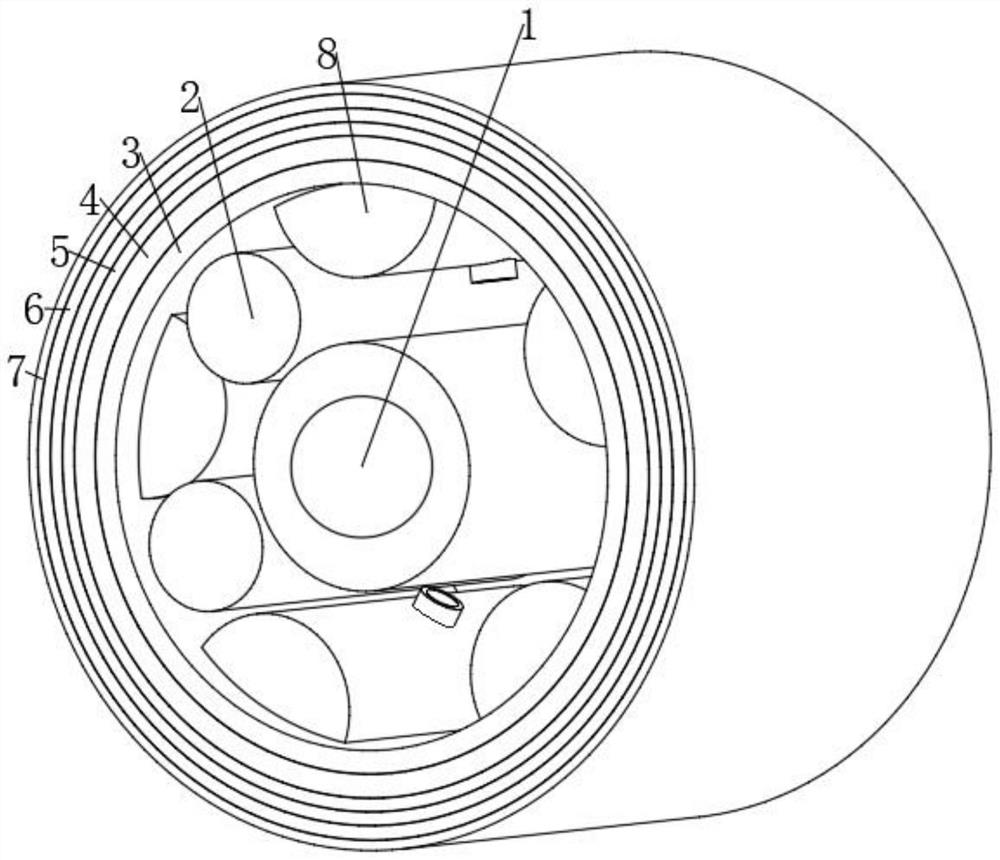

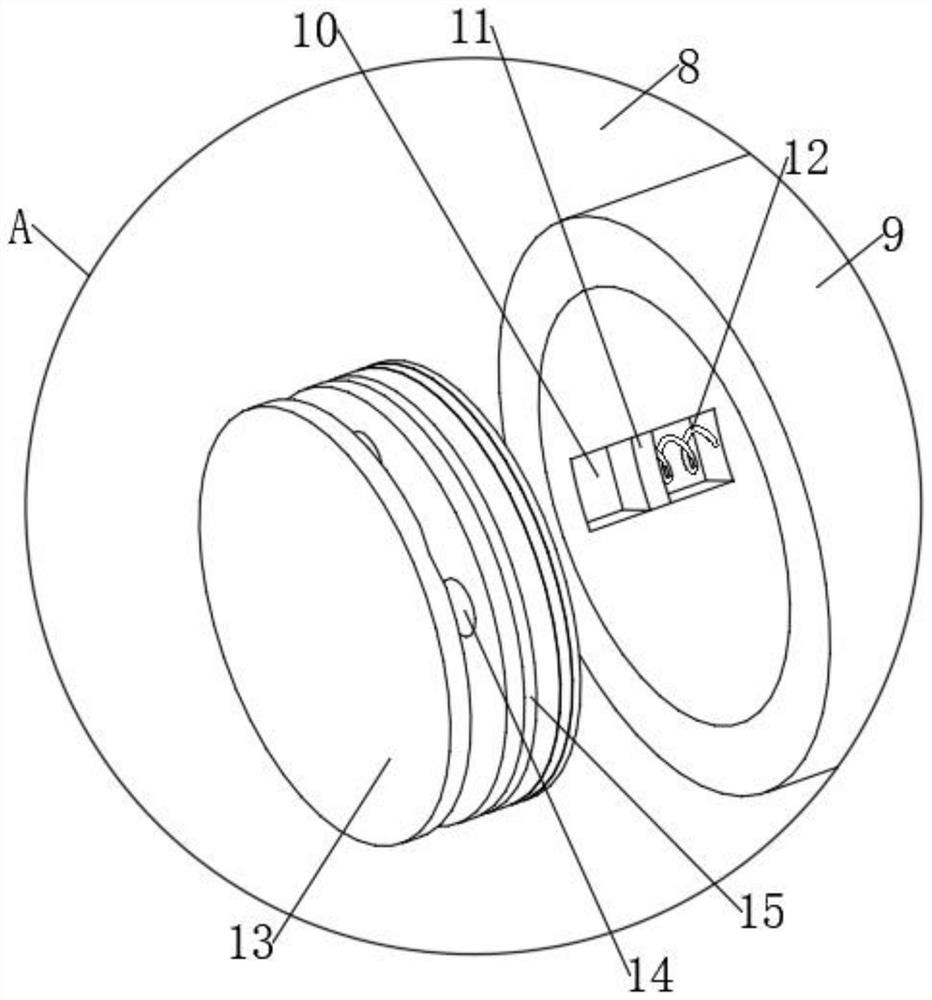

[0035] refer to Figure 1-4 and Figure 8 , a fiber-reinforced resin-based composite core overhead insulated cable, comprising a fiber-reinforced resin-based composite core 1, a plurality of heat-resistant aluminum alloy single wires 2 arranged on the outside of the fiber-reinforced resin-based composite core 1, and a plurality of heat-resistant aluminum alloy single wires 2 The outer side is provided with the same shielding layer 3, and the inner wall of the shielding layer 3 is bonded with a plurality of armored sleeves 8 distributed in a circular array. The armored sleeves 8 are made of metal materials, and the outer wall of the armored sleeve 8 is fixed with an air outlet pipe 9. The inner wall on both sides of the air outlet pipe 9 is provided with a first chute 10, the first chute 10 is slidably connected with a first slider 11, and the first slider 11 and the inner wall of the first chute 10 are fixed with the same The first spring 12, the same exhaust column 13 is fixed...

Embodiment 2

[0043] refer to Figure 5-7 , a fiber-reinforced resin-based composite core overhead insulated cable, the floating mechanism includes an orientation plate 29, the orientation plate 29 is fixed to the bottom inner wall of the installation opening 19 by bolts, and an orientation opening 30 is opened on one side of the orientation plate 29, and the orientation opening 30 slides Connected with an orientation block 31, the side of the orientation block 31 close to the sleeve 20 is fixed with a frame rod 38 by bolts, the cross section of the frame rod 38 is arranged in an L shape, and the other side of the frame rod 38 is fixed with a first pole 39 by bolts, the second A rod 39 and the inner column 21 are fixed by bolts, and the inner wall at the bottom of the installation port 19 is connected with a reciprocating screw rod 34 through bearing rotation. The reciprocating screw rod 34 is threaded with a sleeve block 33. The same connecting rod 32 is fixed by bolts, the top of the reci...

Embodiment 3

[0047] refer to Figure 9-10 , a fiber-reinforced resin-based composite core overhead insulated cable, the bottom of the inner column 21 is bonded with a permanent magnet 45, the bottom inner wall of the embedded groove 28 is fixed with an electromagnet 46 by bolts, and the bottom inner wall of the installation port 19 is fixed with a frame plate 49 by bolts, The top of the frame plate 49 is fixed with a coil winding 50 by bolts, the first shaft 22 is sleeved and fixed with an inner sleeve 47, and the inner sleeve 47 is sleeved and fixed with a ring magnet 48. The ring magnet 48 is arranged at the center of the coil winding 50, and the coil The winding 50 is electrically connected to the electromagnet 46 .

[0048] Working principle: When in use, the first shaft 22 drives the inner sleeve 47 and the ring magnet 48 to rotate, so that a relative motion is formed between the ring magnet 48 and the coil winding 50, so that the coil winding 50 cuts the magnetic induction line and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com