Extreme pressure lubricating grease and preparation method thereof

A technology of extreme pressure grease and extreme pressure agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

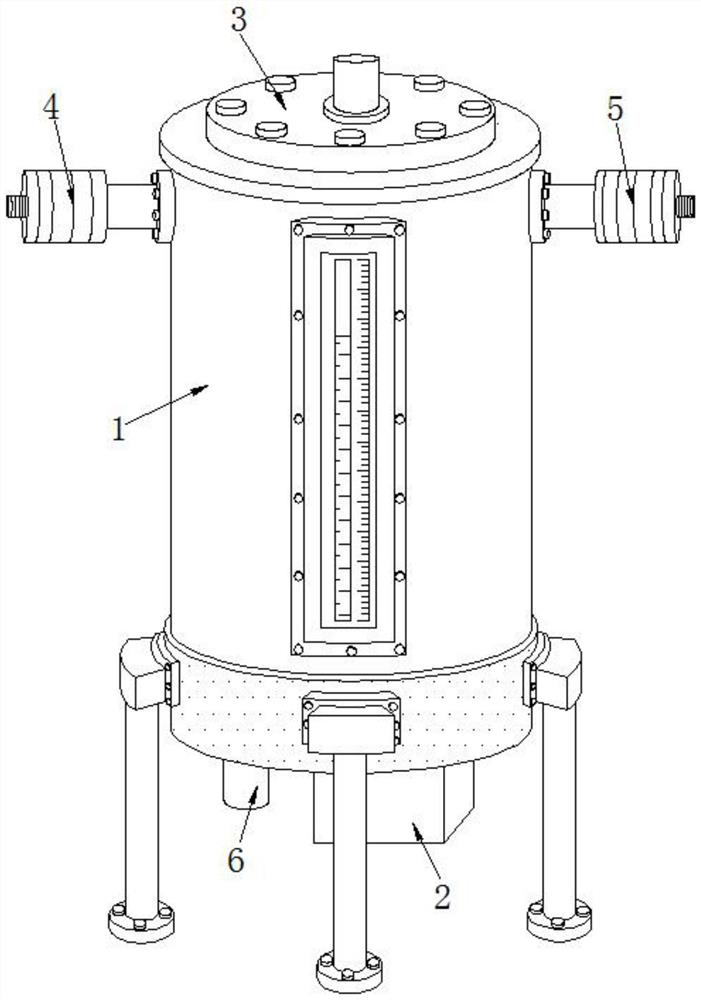

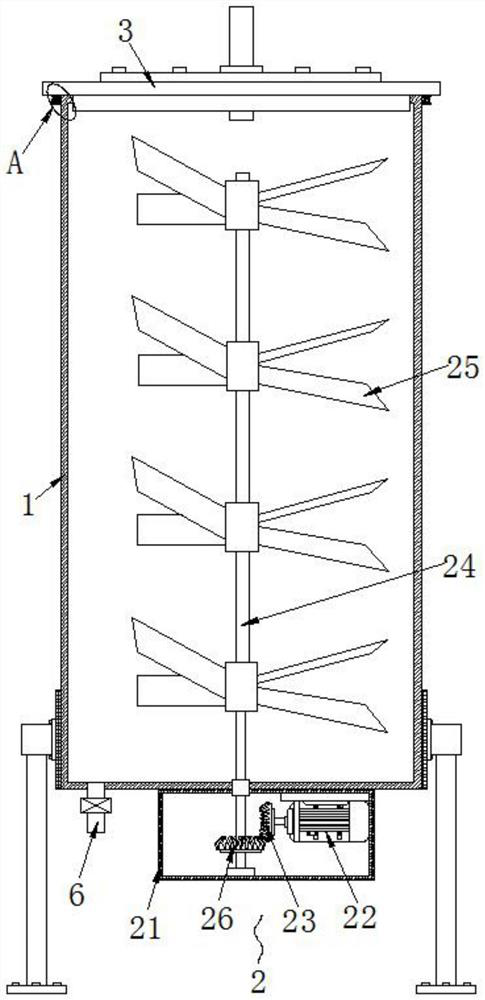

Image

Examples

Embodiment 1

[0039] A kind of extreme pressure lubricating grease, its raw material comprises by weight percentage: soap powder 15%, anti-adhesion composition 2%, boric acid 7%, butyl oleate 2%, compound hydroxide salt 3%, dodecyl alcohol ester 2% %, high temperature resistant additive 1.9%, polyacrylate-styrene copolymerized aqueous emulsion 2%, water 3%, extreme pressure agent 0.7%, pour point depressant 0.7% and base oil balance, anti-blocking composition is liquid paraffin, The composition of talcum powder and xanthan gum, the composite hydroxide salt is a composition of potassium hydroxide, lithium hydroxide and calcium hydroxide, and the high temperature resistant additives are ceramic powder, hindered phenol, hydrogen-containing silicone oil, tall oil ester , a composition of polyisobutylene and random polypropylene, the extreme pressure agent is sodium metaborate, and the pour point depressant is vinyl acetate-fumarate copolymer.

[0040] The embodiment of the present invention als...

Embodiment 2

[0050] A kind of extreme pressure lubricating grease, its raw material comprises by weight percentage: soap powder 10%, anti-adhesion composition 1%, boric acid 5%, butyl oleate 1%, compound hydroxide salt 1%, dodecyl alcohol ester 1% %, high temperature resistant additive 1.5%, polyacrylate-styrene copolymerized aqueous emulsion 1%, water 1%, extreme pressure agent 0.5%, pour point depressant 0.5% and base oil balance, anti-blocking composition is liquid paraffin and The composition of talc powder, the composite hydroxide salt is a composition of potassium hydroxide and lithium hydroxide, the high temperature resistance additive is a composition of ceramic powder, hindered phenol and hydrogen-containing silicone oil, and the extreme pressure agent is a dialkyl dithio Zinc phosphate, and the pour point depressant is vinyl acetate-fumarate copolymer.

[0051] The embodiment of the present invention also provides a preparation method of extreme pressure grease, which specificall...

Embodiment 3

[0061] A kind of extreme pressure lubricating grease, its raw material comprises by weight percentage: soap powder 20%, anti-adhesion composition 3%, boric acid 10%, butyl oleate 3%, compound hydroxide salt 5%, dodecyl alcohol ester 3% %, high temperature resistant additive 2.3%, polyacrylate-styrene copolymerized aqueous emulsion 3%, water 5%, extreme pressure agent 1%, pour point depressant 1% and base oil balance, anti-blocking composition is talcum powder and The composition of xanthan gum, the composite hydroxide salt is a composition of lithium hydroxide and calcium hydroxide, the high temperature resistant additive is a composition of tall oil ester, polyisobutylene and random polypropylene, and the extreme pressure agent is trimethyl phosphate Phenolic ester, pour point depressant is vinyl acetate-fumarate copolymer.

[0062] The embodiment of the present invention also provides a preparation method of extreme pressure grease, which specifically includes the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com