Coral sand improved matrix, improved coral sand and application of improved coral sand

A technology of coral sand and matrix, applied in application, other chemical processes, silicates, etc., can solve the problems of poor pressure bearing performance and water retention effect of coral sand, achieve excellent desalination performance, increase content, and good water retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

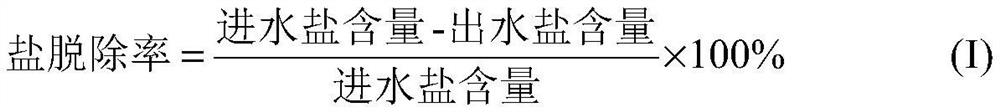

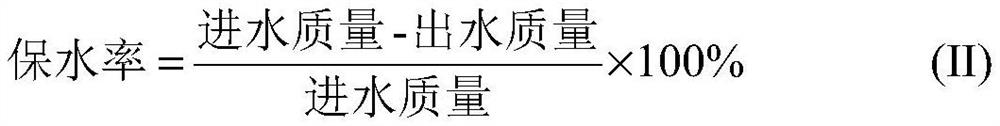

Examples

Embodiment 1

[0031] A coral sand improved substrate, comprising the following components by mass:

[0032] 15 parts of modified absorbent fiber cotton, 10 parts of aluminosilicate, 2 parts of flocculant, 5 parts of coconut shell powder, 3 parts of soil structure stabilizer and 30 parts of bentonite; the soil structure stabilizer consists of carboxymethyl cellulose and polyacrylic acid Ammonium is mixed at a mass ratio of 1:2.

[0033] Wherein, the modified fiber cotton is obtained through the following steps:

[0034] S1: Mix acrylic acid, polyethylene glycol 600, polyurethane emulsion, water-based epoxy resin emulsion and water in a mass ratio of 10:6:5:4:30, and mix well to obtain a modified solution;

[0035] S2: Submerge the porous fiber cotton with a diameter of 4 μm in the modification solution, ultrasonically treat it at a frequency of 25 kHz for 1 hour, then take it out, air-dry it, and pulverize it.

[0036] Aluminosilicates are prepared by the following steps:

[0037] S1: Mix...

Embodiment 2

[0046] A coral sand improved substrate, comprising the following components by mass:

[0047] 10 parts of modified absorbent fiber cotton, 15 parts of aluminosilicate, 1 part of flocculant, 10 parts of coconut shell powder, 2 parts of soil structure stabilizer and 40 parts of bentonite; the soil structure stabilizer consists of carboxymethyl cellulose and polyacrylic acid Ammonium is mixed at a mass ratio of 1:1.

[0048]Wherein, the modified fiber cotton is obtained through the following steps:

[0049] S1: Mix acrylic acid, polyethylene glycol 600, polyurethane emulsion, water-based epoxy resin emulsion and water at a mass ratio of 8:8:4:5:25, and mix well to obtain a modified solution;

[0050] S2: Submerge the porous fiber cotton with a diameter of 3 μm in the modification solution, ultrasonically treat it at a frequency of 20 kHz for 1 hour, then take it out, air-dry it, and pulverize it.

[0051] Aluminosilicates are prepared by the following steps:

[0052] S1: Mix s...

Embodiment 3

[0061] A coral sand improved substrate, comprising the following components by mass:

[0062] 20 parts of modified absorbent fiber cotton, 8 parts of aluminosilicate, 3 parts of flocculant, 5 parts of coconut shell powder, 5 parts of soil structure stabilizer and 20 parts of bentonite; the soil structure stabilizer consists of carboxymethyl cellulose and polyacrylic acid Ammonium is mixed at a mass ratio of 1:3.

[0063] Wherein, the modified fiber cotton is obtained through the following steps:

[0064] S1: Mix acrylic acid, polyethylene glycol 600, polyurethane emulsion, water-based epoxy resin emulsion and water at a mass ratio of 12:5:6:3:35, and mix well to obtain a modified solution;

[0065] S2: Submerge the porous fiber cotton with a diameter of 5 μm in the modification solution, ultrasonically treat it at a frequency of 30 kHz for 0.5 h, then take it out, air-dry it, and pulverize it.

[0066] Aluminosilicates are prepared by the following steps:

[0067] S1: Mix s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com