Preparation method of electrostatically-spun seawater desalination membrane with self-floating structure

An electrospinning and self-floating technology, applied in electrospinning, chemical instruments and methods, seawater treatment, etc., to achieve the effect of reducing the difficulty of the production process, good desalination effect, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

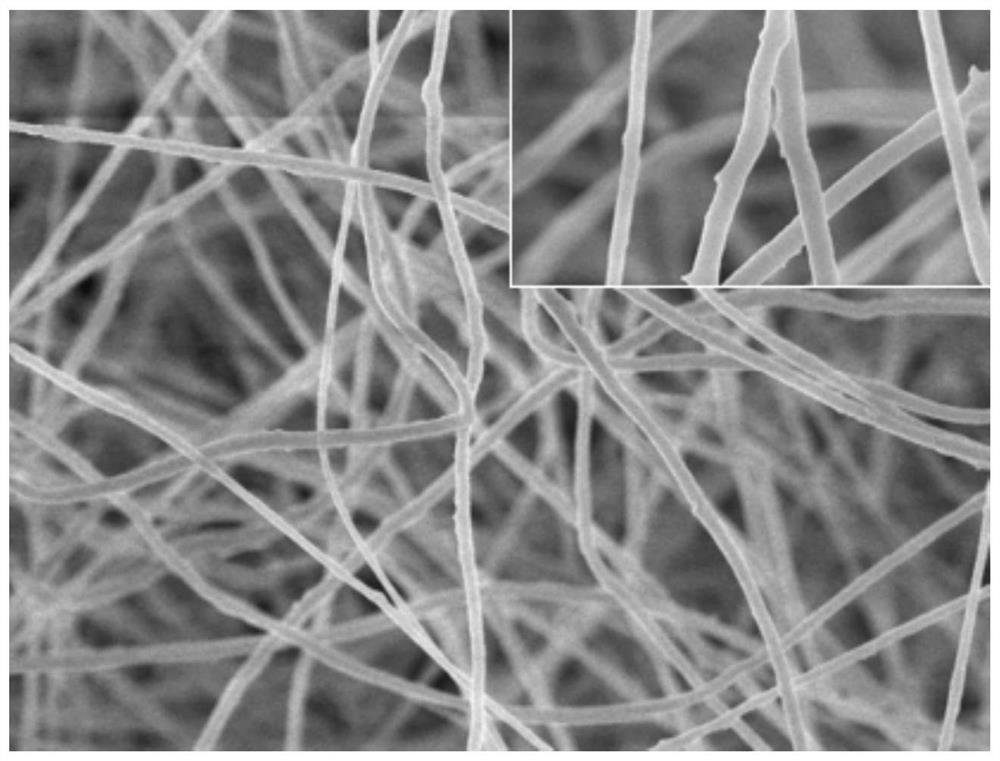

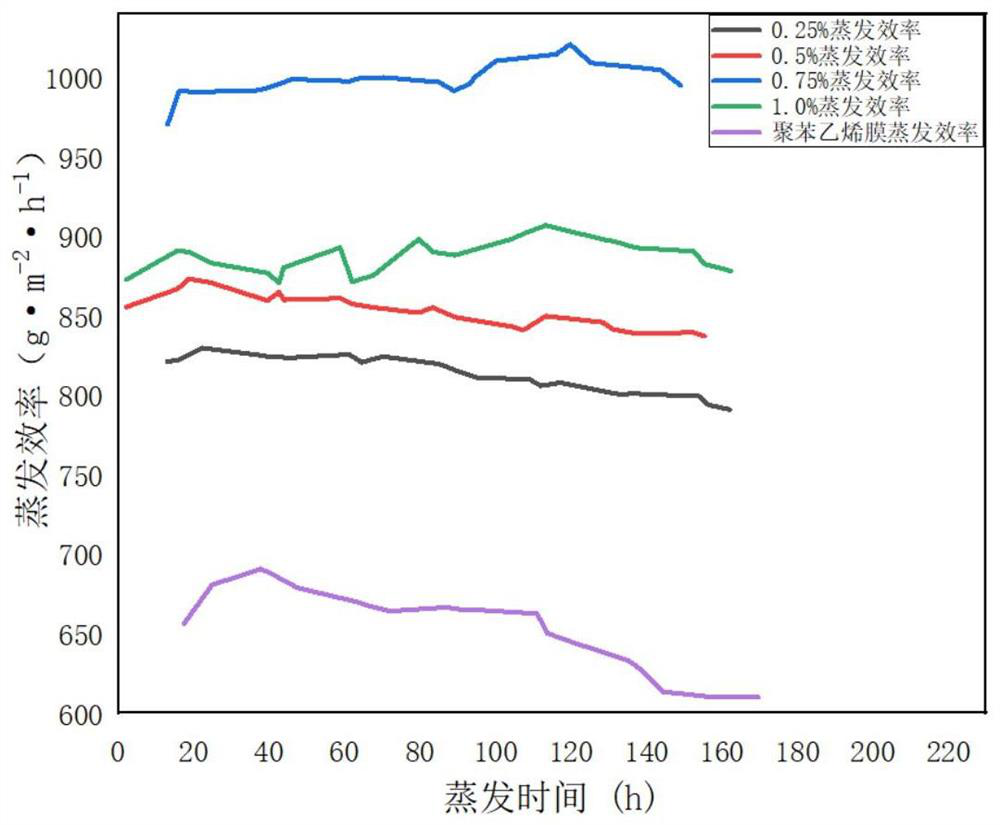

[0031] A preparation method of an electrospun seawater desalination membrane with a self-floating structure, the thickness of the electrospun seawater desalination membrane with a self-floating structure is 0.5mm, and the thickness ratio of the polyacrylonitrile layer to the polystyrene layer is 1: 1.5, the amount of carbon material added is 0.75wt%, and the average desalination efficiency is 994g / (m 2 h), the surface temperature of the fiber membrane reaches 95° C. after two hours of photothermal evaporation.

[0032] Firstly, polystyrene spinning solution and carbon-doped polyacrylonitrile spinning solution were prepared; then, carbon-doped polyacrylonitrile nanofiber membrane was prepared by electrospinning process; finally, the polyacrylonitrile nanofiber membrane was continued Spinning, preparing a polystyrene nanofiber membrane, and drying it to finally obtain an electrospun seawater desalination membrane with a self-floating structure.

[0033]A method for preparing an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com