Low-yellowing material fading prevention UV primer and preparation method thereof

A material and low-yellow technology, applied in the field of low-yellowing and anti-fading UV primer and its preparation field, can solve the problems of affecting the quality of dyed wood furniture, easy discoloration of dyed wood, fading of dyed wood, etc., and improve UV curing. Moderate performance, hardness and flexibility, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

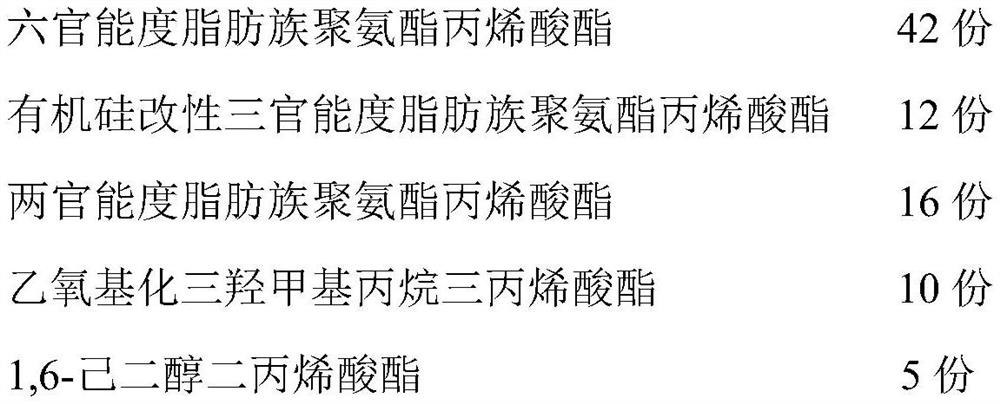

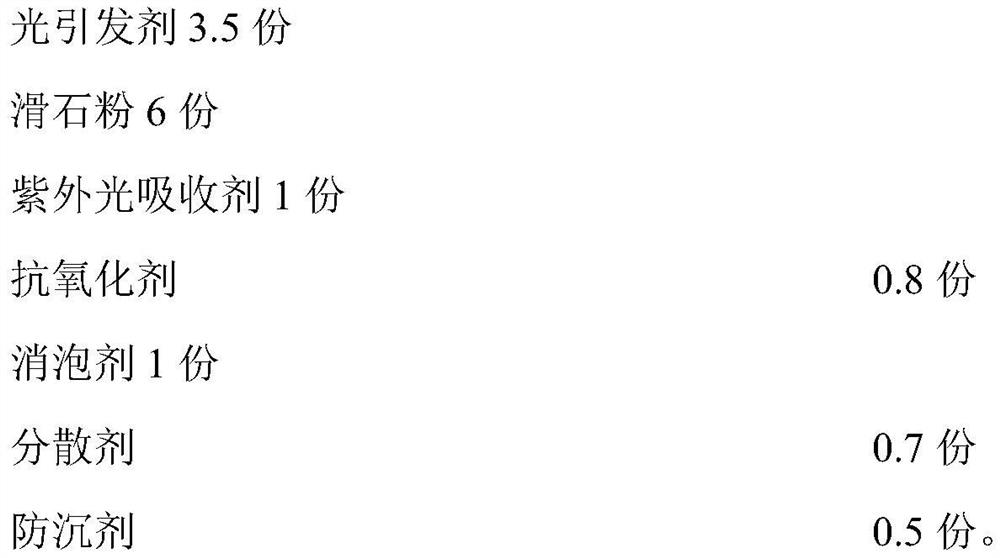

[0034] A kind of low-yellowing anti-fading UV primer of the present embodiment consists of the following raw materials in parts by weight:

[0035]

[0036]

[0037] Among them, the photoinitiator is composed of methyl benzoylformate and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide in a mass ratio of 1:0.1.

[0038] Among them, the ultraviolet light absorber is composed of a benzotriazole ultraviolet absorber and a hindered amine ultraviolet absorber in a mass ratio of 1:0.8. The benzotriazole UV absorber is 2-(2′-hydroxyl-3′,5′-di-tert-phenyl)-5-chlorinated benzotriazole. The hindered amine UV absorber is composed of UV-770 and UV-3853 in a mass ratio of 1:0.6. The antioxidant is a phosphite antioxidant.

[0039] Wherein, the particle size of the talcum powder is 500 mesh. The defoamer is an acrylic defoamer. The dispersant is a polymer dispersant. The anti-settling agent is fumed silica.

[0040] A kind of preparation method of the UV primer of anti-yellowing a...

Embodiment 2

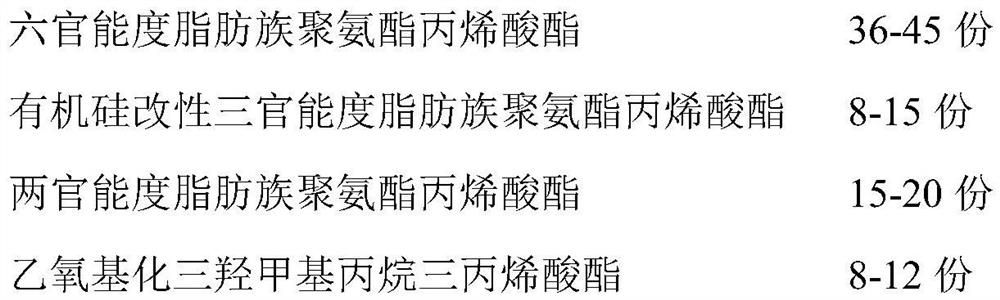

[0045] A kind of low-yellowing anti-fading UV primer of the present embodiment consists of the following raw materials in parts by weight:

[0046]

[0047]

[0048] Among them, the photoinitiator is composed of methyl benzoylformate and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide in a mass ratio of 1:0.3.

[0049] Among them, the ultraviolet light absorber is composed of a benzotriazole ultraviolet absorber and a hindered amine ultraviolet absorber in a mass ratio of 1:0.5. Benzotriazole UV absorber consists of 2-(2ˊ-hydroxy-3ˊ,5ˊ-di-tert-phenyl)-5-chlorinated benzotriazole and 2-(2ˊ-hydroxy-5ˊ-methylphenyl)benzo Triazoles are composed at a mass ratio of 1:0.2. The hindered amine UV absorber is UV-770. The antioxidant is composed of hindered phenolic antioxidant and phosphite antioxidant in a mass ratio of 1:1.

[0050] Wherein, the particle size of talcum powder is 400 mesh. The defoamer is an acrylic defoamer. The dispersant is a polymer dispersant. The anti-...

Embodiment 3

[0056] A kind of low-yellowing anti-fading UV primer of the present embodiment consists of the following raw materials in parts by weight:

[0057]

[0058]

[0059] Among them, the photoinitiator is composed of methyl benzoylformate and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide in a mass ratio of 1:0.5.

[0060] Among them, the ultraviolet light absorber is composed of a benzotriazole ultraviolet absorber and a hindered amine ultraviolet absorber in a mass ratio of 1:0.8. Benzotriazole UV absorber consists of 2-(2ˊ-hydroxy-3ˊ,5ˊ-di-tert-phenyl)-5-chlorinated benzotriazole and 2-(2ˊ-hydroxy-5ˊ-methylphenyl)benzo Triazoles are composed at a mass ratio of 1:0.2. The hindered amine UV absorber is composed of UV-770 and UV-622 in a mass ratio of 1:0.3. The antioxidant is a phosphite antioxidant. The antioxidant is a hindered phenolic antioxidant.

[0061] Wherein, the particle size of the talcum powder is 350 mesh. The defoamer is an acrylic defoamer. The dispersa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com