Graphene oxide-butyronitrile latex composite foam material and preparation method thereof

A technology of syntactic foam and nitrile rubber, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of affecting the electrical conductivity of composite materials, strong van der Waals force between GO sheets, unfavorable dispersion, etc., and achieve a good solvent. Adsorption capacity, rich pore structure, improving the effect of agglomeration and uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

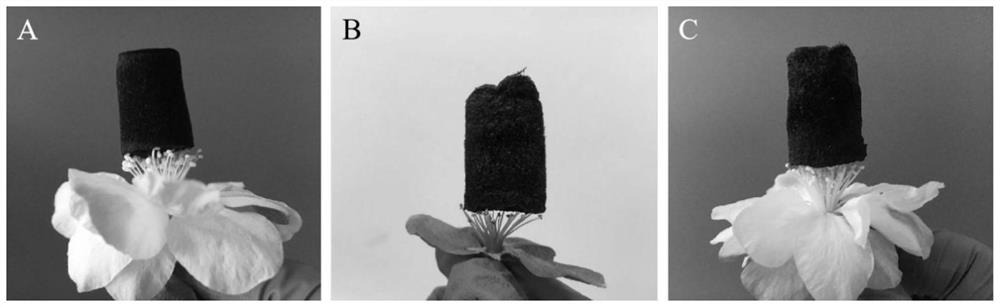

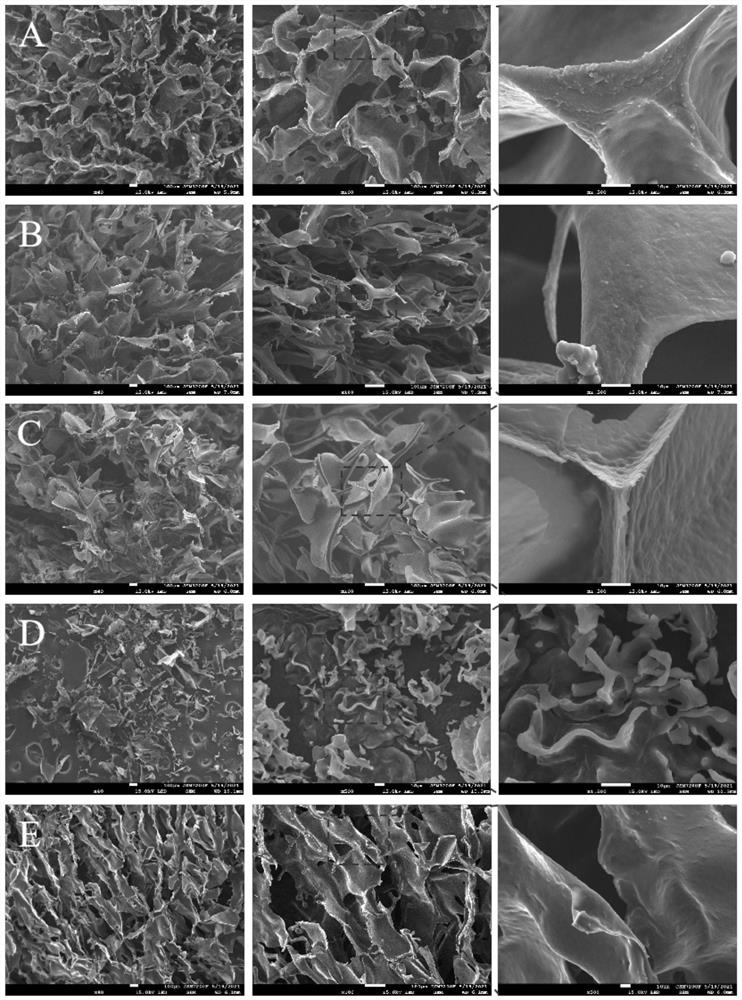

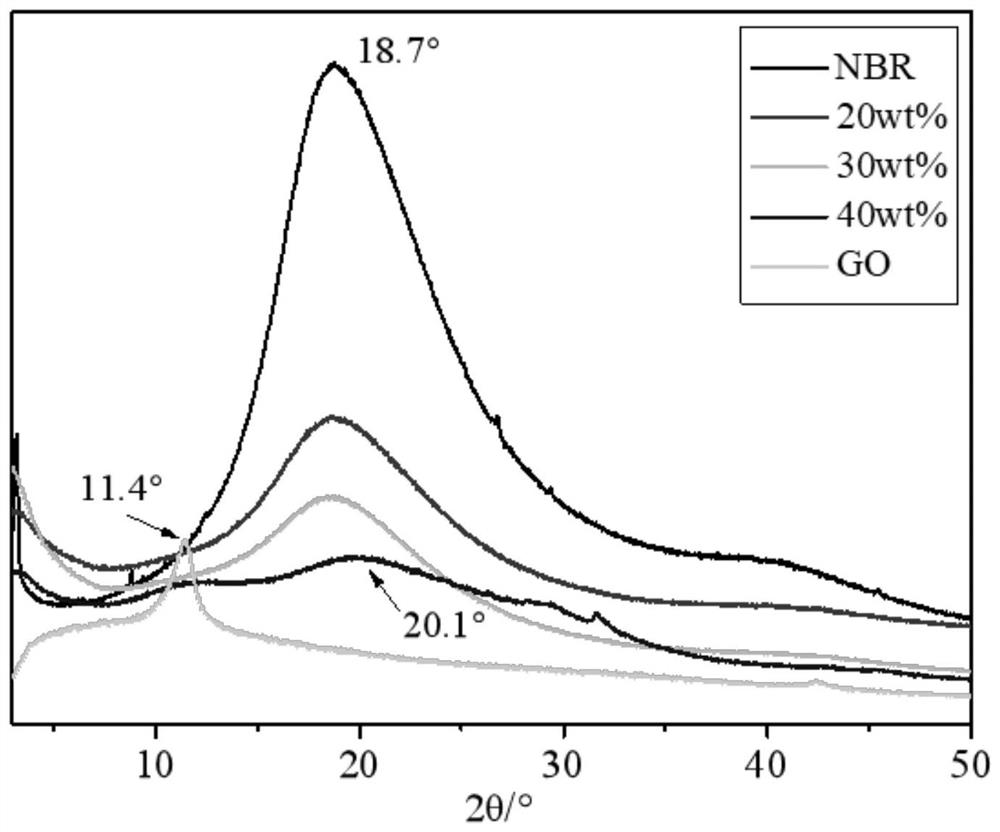

Image

Examples

Embodiment 1

[0048] 1.1 Preparation of PVP modified GO dispersion:

[0049]Prepare an aqueous solution of GO with a concentration of 9 mg / mL, ultrasonically disperse it for 3 hours, and then process it in a high-speed centrifuge at 20,000 r / min for 10 minutes to remove unpeeled and unevenly dispersed GO sheets to prepare an aqueous dispersion of GO;

[0050] According to the mass ratio of PVP to GO of 1:1, PVP was put into the aqueous dispersion of GO, and ultrasonic dispersion was continued for 5 h to obtain a stable and uniform dispersion of PVP-modified GO.

[0051] 1.2 Preparation of GO-NBR mixed dispersion:

[0052] Put the dispersion of PVP modified GO in NBR latex, and mix it uniformly with 700r / min magnetic stirring at room temperature for 1h to make a mixed dispersion of GO and NBR. The mass ratio of GO to NBR is 20mg:80mg. Add 28wt% ammonia water dropwise to the solution to adjust the pH value of the solution to 10. At this time, both the GO solution and the NBR latex are negati...

Embodiment 2

[0058] The difference between this embodiment and embodiment 1 is:

[0059] In step 1.1, the aqueous solution concentration of the GO of configuration is 9mg / mL, and in the mixed dispersion liquid of GO and NBR made in step 1.2, the mass ratio of GO and NBR is 30mg:70mg; In step 1.4, composite foam matrix material The heating temperature is 170° C., and the heating time is 170 minutes.

Embodiment 3

[0061] The difference between this embodiment and embodiment 1 is:

[0062] In step 1.2, the aqueous solution concentration of the GO of configuration is 9mg / mL, and in the mixed dispersion liquid of GO and NBR of making, the mass ratio of GO and NBR is 40mg:60mg; In step 1.4, the heating temperature of composite foam matrix material is 200°C, heating time is 120min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com