Triphenylmethane polyether carboxylate, composition and preparation method thereof, and extra-heavy oil and super-heavy oil CO2 exploitation method

A technology of polyether carboxylate and triphenylmethane, which is applied in the fields of extra-heavy oil and super-heavy oil CO2 exploitation, triphenylmethane polyether carboxylate and its composition, can solve the problem of low viscosity reduction efficiency and slow dissolution rate , low solubility and other problems, to achieve the effect of improving the viscosity reduction rate and the dissolved gas-oil ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

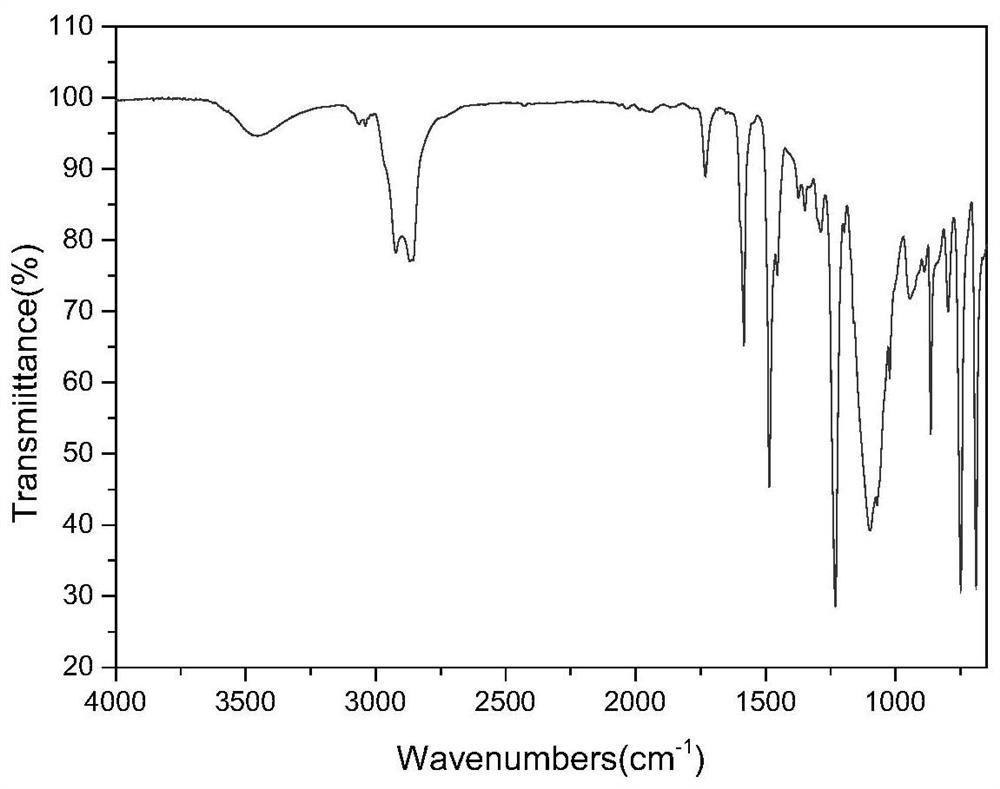

[0098] (a) preparation of triphenylmethane polyether carboxylate:

[0099] 1. Add 292g (1mol) 4,4',4"-trihydroxytriphenylmethane, 4.0g potassium hydroxide to the pressure reactor, and remove the air in the reaction flask by vacuum. N 2 Under protection, the system was heated to 120° C., and 174 g (3 mol) of propylene oxide was slowly introduced to control the pressure to ≤0.20 MPa. After the reaction, the low boilers were removed under reduced pressure, neutralized and dehydrated after cooling to obtain 445.5 g of triphenylmethane polyoxypropylene (n=3) ether, with a yield of 95.6%.

[0100] ②Add 233g (0.5mol) of triphenylmethane polyoxypropylene (n=3) ether, 114g (0.5mol) of myristic acid, 2.0g of sodium bicarbonate into the dry reactor, and remove the oxygen in vacuum. in N 2 Under protection, the system was heated to 220°C and reacted for 3h. After cooling, it was neutralized and dehydrated to obtain 316.8 g of triphenylmethane polyoxypropylene (n=3) ether myristate (m=1...

Embodiment 2

[0106] (a) preparation of triphenylmethane polyether carboxylate:

[0107] 1. Add 292g (1mol) 4 in the pressure reactor, 4 ', 4 "-trihydroxytriphenylmethane, 4.0g potassium hydroxide, vacuum remove the air in the reaction flask. N 2 Under protection, the system was heated to 110° C., and 132 g (3 mol) of ethylene oxide was slowly introduced to control the pressure to ≤0.10 MPa. After the reaction, the low boilers were removed under reduced pressure, neutralized and dehydrated after cooling to obtain 407.9 g of triphenylmethane polyoxyethylene (n=3) ether, with a yield of 96.2%.

[0108] ②Add 212g (0.5mol) triphenylmethane polyoxyethylene (n=3) ether, 114g (0.5mol) myristic acid, 2.0g sodium bicarbonate to the dry reactor, and remove oxygen in vacuum. in N 2 Under protection, the system was heated to 210°C and reacted for 3h. After cooling, it was neutralized and dehydrated to obtain 311.0 g of triphenylmethane polyoxyethylene (n=3) ether myristate (m=1.0) ester, with a yiel...

Embodiment 3

[0114] (a) preparation of triphenylmethane polyether carboxylate:

[0115] 1. Add 292g (1mol) 4 in the pressure reactor, 4 ', 4 "-trihydroxytriphenylmethane, 4.0g potassium hydroxide, vacuum remove the air in the reaction flask. N 2 Under protection, the system was heated to 120° C., and 174 g (3 mol) of propylene oxide was slowly introduced to control the pressure to ≤0.20 MPa. After the reaction, the low boilers were removed under reduced pressure, neutralized and dehydrated after cooling to obtain 445.5 g of triphenylmethane polyoxypropylene (n=3) ether, with a yield of 95.6%.

[0116] ②Add 233g (0.5mol) of triphenylmethane polyoxypropylene (n=3) ether, 114g (0.5mol) of myristic acid, 2.0g of sodium bicarbonate into the dry reactor, and remove the oxygen in vacuum. in N 2 Under protection, the system was heated to 220°C and reacted for 3h. After cooling, it was neutralized and dehydrated to obtain 316.8 g of triphenylmethane polyoxypropylene (n=3) ether myristate (m=1.0)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com