Preparation method of multi-morphology coexisting MgAlON refractory material for RH (Ruhrstahl Heraeus) refining furnace

A refractory material, magnesium aron technology, applied in the field of refractory materials, can solve the problems that the mechanical properties and thermal shock stability of refractory materials cannot be taken into account at the same time, so as to achieve the improvement of anti-permeability and thermal shock stability, reduce the pore diameter, and improve the The effect of thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

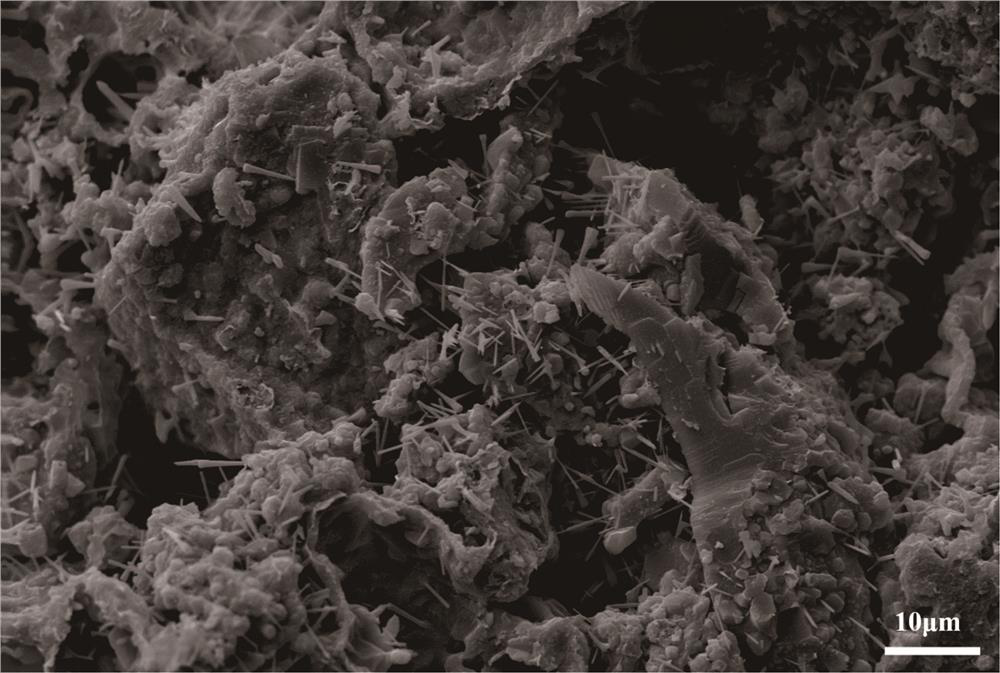

Image

Examples

Embodiment 1

[0017] A method for preparing a MgAlON refractory material with coexistence of multiple shapes for RH refining furnaces. Aggregate magnesia particles, matrix and magnesium aluminate sol binder with a weight percentage of 4% are uniformly mixed to form a raw material mixture, wherein the aggregate The magnesia particles are fused magnesia with a purity of 96%. The weight percentage of the magnesia particles with a particle size of 5-3mm is 11wt%, and the weight percentage of the magnesia particles with a particle size of 3-1mm is 30wt%. The weight percentage of -0mm magnesia particles is 30wt%, and the matrix is metal aluminum powder with a particle size of ≤74 μm, a weight percentage of 10wt%, and a purity of 99.3% and a particle size of ≤74 μm, a weight percentage of 13wt%, and a purity of It is a mixture of 96% fused magnesia and activated alumina with a particle size of ≤5 μm, a weight percentage of 6 wt%, and a purity of 99.4%. Weigh fused magnesia particles, metal alumin...

Embodiment 2

[0019] A method for preparing a MgAlON refractory material coexisting with multi-morphology for RH refining furnaces. Aggregate magnesia particles, matrix, and binder pulp waste liquid with a weight percentage of 4.5% are uniformly mixed to form a raw material mixture, wherein the magnesium in the aggregate The sand particles are sintered magnesia with a purity of 98%: the mass percentage of magnesia particles with a particle size of 5-3mm is 12wt%, and the mass percent composition of magnesia particles with a particle size of 3-1mm is 27wt%. The mass percentage of magnesia particles with a particle size of 1-0 mm is 32 wt%, and the matrix is: metal aluminum powder with a particle size of ≤74 μm, a weight percentage of 12 wt%, a purity of 99.3%, and a particle size of ≤74 μm, a weight percentage of A mixture of sintered magnesia with a particle size of 10wt% and a purity of 98% and activated alumina powder with a particle size of ≤5 μm and a weight percentage of 7wt% and a puri...

Embodiment 3

[0021] A method for preparing a MgAlON refractory material with multiple shapes coexisting for RH refining furnaces, mixing aggregate particles, matrix, and binder phenolic resin with a weight percentage of 3.5% to form a raw material mixture, wherein the magnesia particles in the aggregate It is high-purity magnesia with a purity of 97%, and the particles are 9 wt% of magnesia particles with a particle size of 5-3mm, and 33 wt% of magnesia particles with a particle size of 3-1mm, and magnesia with a mass percentage of 1-0mm. The mass percentage of sand particles is 29 wt%, and the matrix is: metal aluminum powder with a particle size of ≤74 μm, a mass percentage of 9 wt%, and a purity of 99.3% and a particle size of ≤74 μm, a mass percentage of 12 wt%, and a purity of 97.8 % of high-purity magnesia and a mixture of activated alumina powder with a particle size of ≤5 μm, a mass percentage of 8wt%, and a purity of 99.4%, take high-purity magnesia particle raw materials and metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com