Porous heat dissipation heat sink and manufacturing method thereof

A technology of heat dissipation heat sink and manufacturing method, which is applied in the direction of laser components, semiconductor lasers, electrical components, etc., can solve the problems of unsuitable chip heat dissipation heat sink, large pore size, and overall size limitation, so as to achieve enhanced bonding force, Effect of reducing volume and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

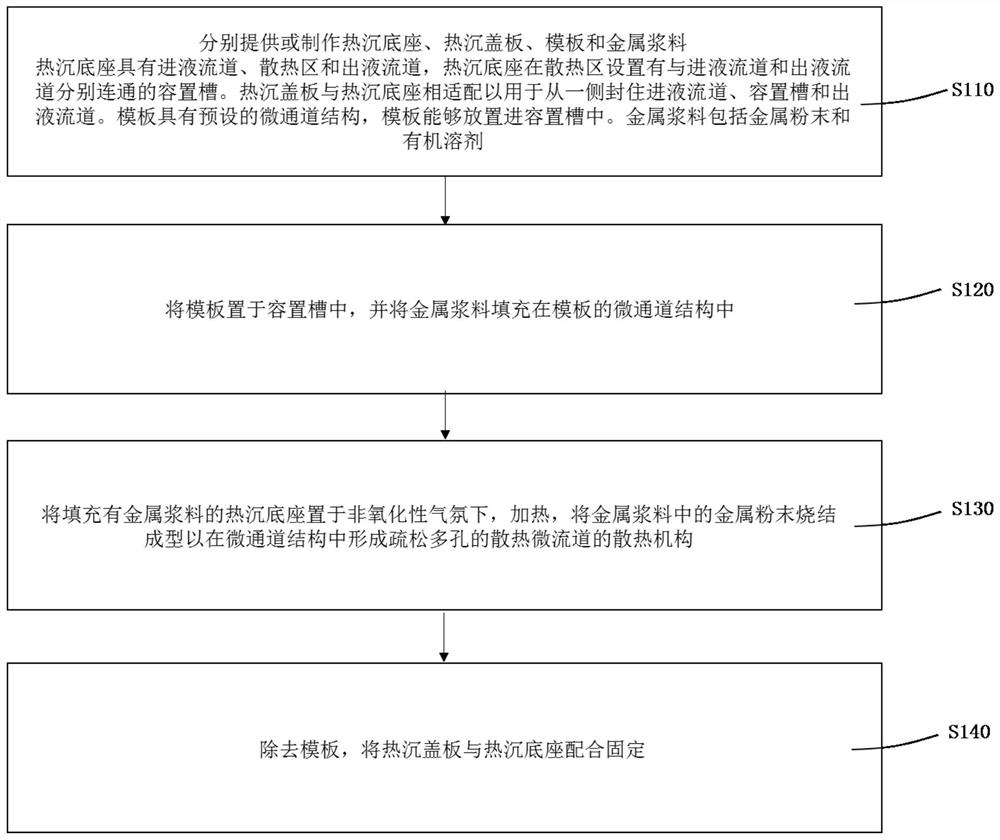

[0077] The method of manufacturing the porous heat sink of the following embodiment includes step one to fourth steps as follows.

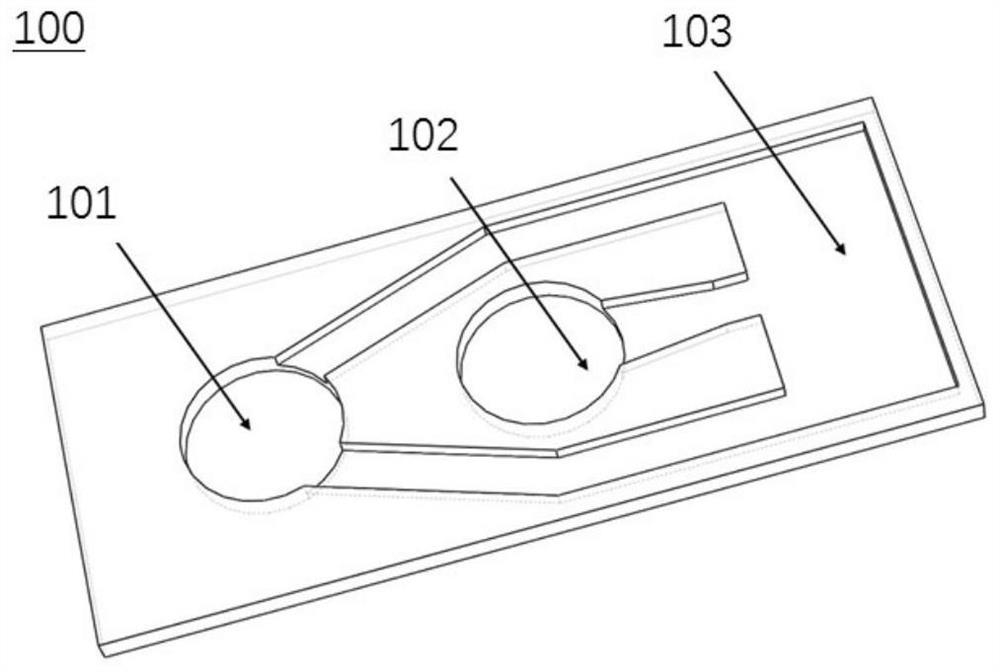

[0078] Step 1: figure 2 with image 3 As shown, a thermal sink base 100, a thermal sink 400, a template 200, and a metal slurry 300 are provided, respectively.

[0079] Among them, the heat sink base 100 has an in-liquid flow channel 102, the heat dissipation zone, and the liquid flow channel 101, and the heat sink base 100 is provided with a receiving groove 103 that communicates with the in-liquid flow channel 102 and the liquid flow channel 101, respectively. . The heat sink 400 is adapted to the heat sink base 100 for sealing the liquid flow channel 102, the accommodating groove 103, and the liquid flow channel 101 from one side. The template 200 has a preset microchannel structure, and the template 200 is fitted to the accommodating groove 103. The metal slurry 300 includes a metal powder, a reducing agent, an organic solvent, a thickener.

[0080...

Embodiment 2

[0091] The method for producing the porous heat sink of Example 2 is substantially the same as in Example 1, and the different places in the configuration of a metal slurry.

[0092] The configuration method of the metal slurry 300 is: a copper powder of 80 μm and a particle diameter of 30 μm and a particle diameter of 30 μm in mass ratio 1: 1, mixed with a propionate containing lactic acid, then adding thickener ethylcellulose. , Stir evenly and form a viscosity of 150 Pa. The metal slurry of S is 300, wherein the copper powder, lactic acid, propylene glycol, and ethylcellulose are 23%, 10%, 60%, 7%;

[0093] The porosity of the heat dissipation mechanism for preparing the obtained porous cooling heat sink is 53.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com