Transparent microcrystalline glass with high elastic modulus and high hardness and preparation method

A glass-ceramic, high-hardness technology, used in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of reduced production efficiency, low elastic modulus, and high cost, and achieve improved structure, elastic modulus and Low hardness and low impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Raw material (wt%): 32% SiO 2 ;29%Al 2 o 3 ;31%Y 2 o 3 ;4%ZrO 2 ; 1%Na 2 O; 2% Li 2 O; 1% B 2 o 3 ;Accurately weigh various raw materials according to the designed glass composition, mix and stir the batch materials evenly, put them into a platinum crucible and melt them at 1560°C for 24 hours, heat preservation and annealing at 650°C for 5 hours after casting and cooling with the furnace, the heat treatment process is : The nucleation temperature is 750°C, the nucleation time is 6h, the crystallization temperature is 810°C, and the crystallization time is 2h. After the heat treatment, it is cooled with the furnace to obtain glass-ceramics.

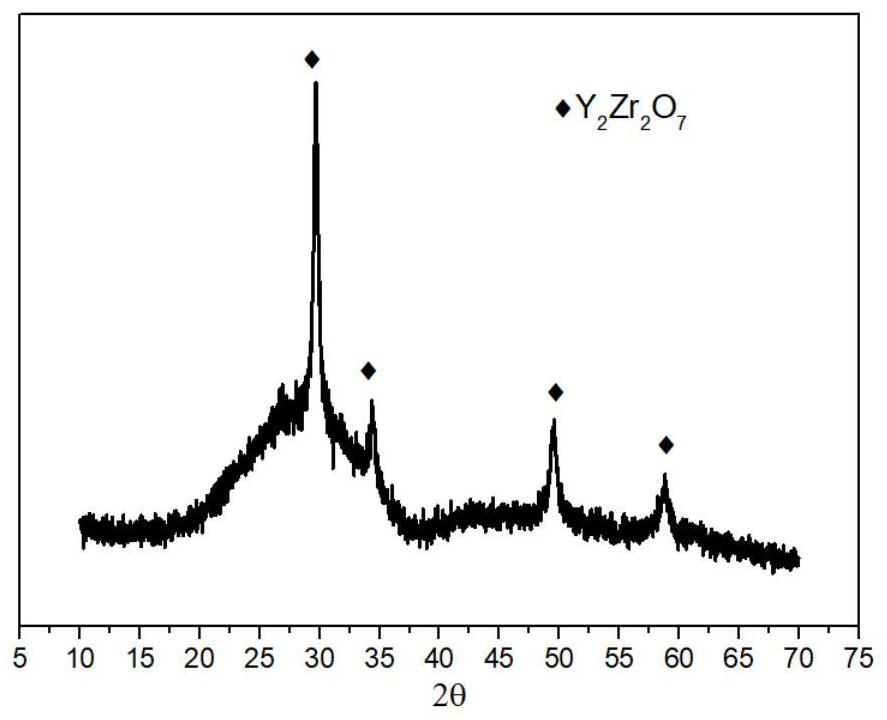

[0044] The main crystal phase Y of the obtained glass-ceramic 2 Zr 2 o 7 , the elastic modulus is 130GPa, the microhardness is 860MPa, and the visible light transmittance at 300-780nm of the glass-ceramic with a thickness of 0.65mm is 90%.

[0045] After further chemical strengthening, the depth of the stress layer is 1...

Embodiment 2

[0047] Raw material (wt%): 29% SiO 2 ;30%Al 2 o 3 ;31%Y 2 o 3 ;4%ZrO 2 ;2%Na 2 O; 3% Li 2 O; 1% B 2 o 3Accurately weigh various raw materials according to the designed glass composition, mix and stir the batch materials evenly, put them into a platinum crucible for melting at 1580°C for 20 hours, heat preservation and annealing at 650°C for 3 hours after casting and cooling in the furnace. The heat treatment process is: nucleation temperature 780°C, nucleation time 10h, crystallization temperature 860°C, crystallization time 1h, after the heat treatment is completed, it is cooled in the furnace to obtain glass-ceramics.

[0048] The main crystal phase Y of the obtained glass-ceramic 2 Zr 2 o 7 , the elastic modulus is 125GPa, the microhardness is 876MPa, and the visible light transmittance of the glass-ceramic with a thickness of 0.65mm is 89.5% at 300-800nm.

[0049] After further chemical strengthening, the depth of the stress layer is 108μm, the surface compress...

Embodiment 3

[0051] Raw material (wt%): 30% SiO 2 ;29%Al 2 o 3 ;30%Y 2 o 3 ;5% ZrO 2 ;2%Na 2 O; 3.5% Li 2 O; 0.5% B 2 o 3 ;Accurately weigh various raw materials according to the designed glass composition, mix and stir the batch materials evenly, put them into a platinum crucible for melting at 1580°C for 20 hours, heat preservation and annealing at 650°C for 2 hours after casting and cooling in the furnace. The heat treatment process is: nucleation temperature 760°C, nucleation time 10h, crystallization temperature 860°C, crystallization time 1h, after the heat treatment is completed, it is cooled in the furnace to obtain glass-ceramics.

[0052] The main crystal phase Y of the obtained glass-ceramic 2 Zr 2 o 7 , the elastic modulus is 125GPa, the microhardness is 874MPa, and the visible light transmittance of 0.65mm-thick glass-ceramics at 300-800nm is 89.3%.

[0053] After further chemical strengthening, the depth of the stress layer is 118μm, the surface compressive stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com