Efficient cache type curing machine for perovskite solar photovoltaic production

A perovskite solar energy, cache technology, applied in conveyors, conveyor objects, furnaces, etc., can solve problems such as unfavorable work efficiency, small occupied space, and large conveying area, saving horizontal occupied space and increasing cache space. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

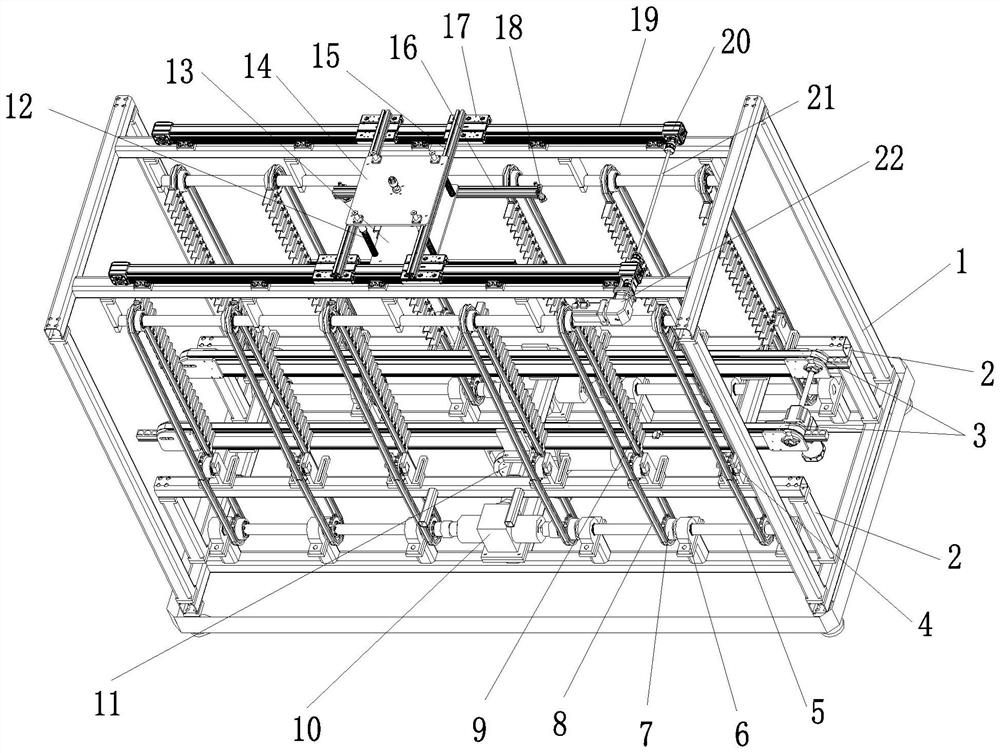

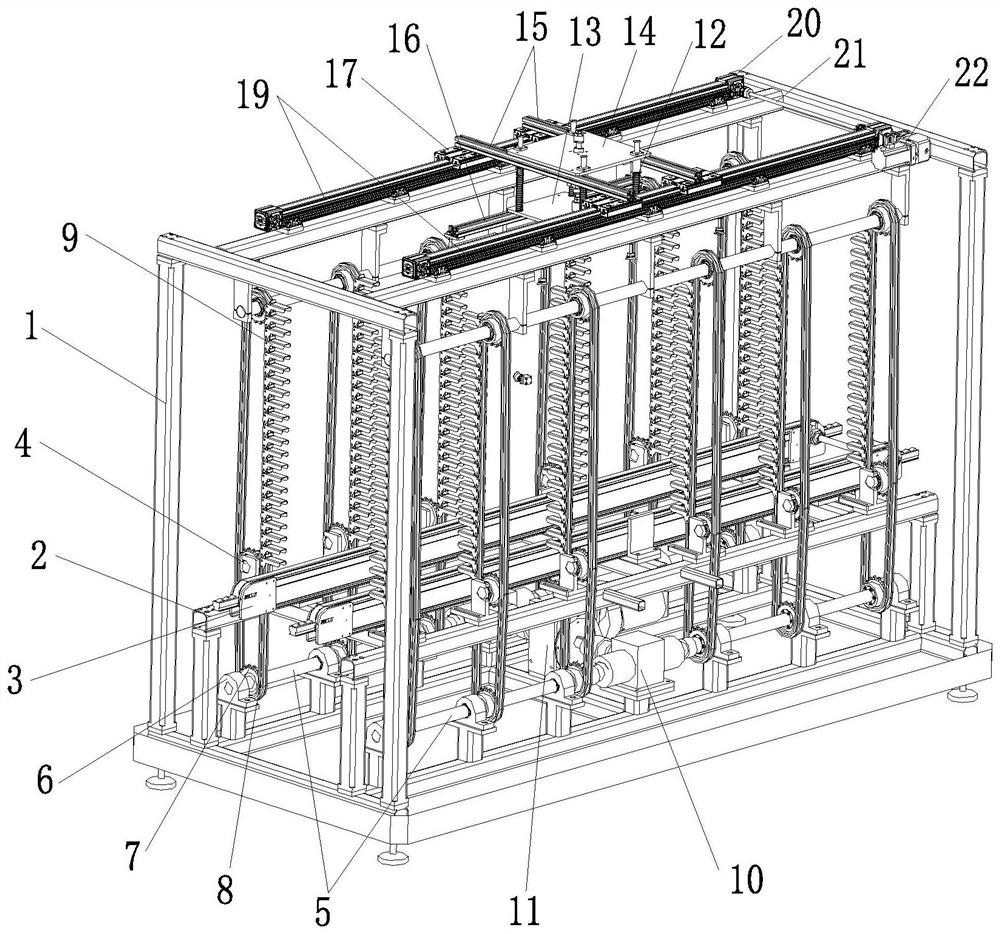

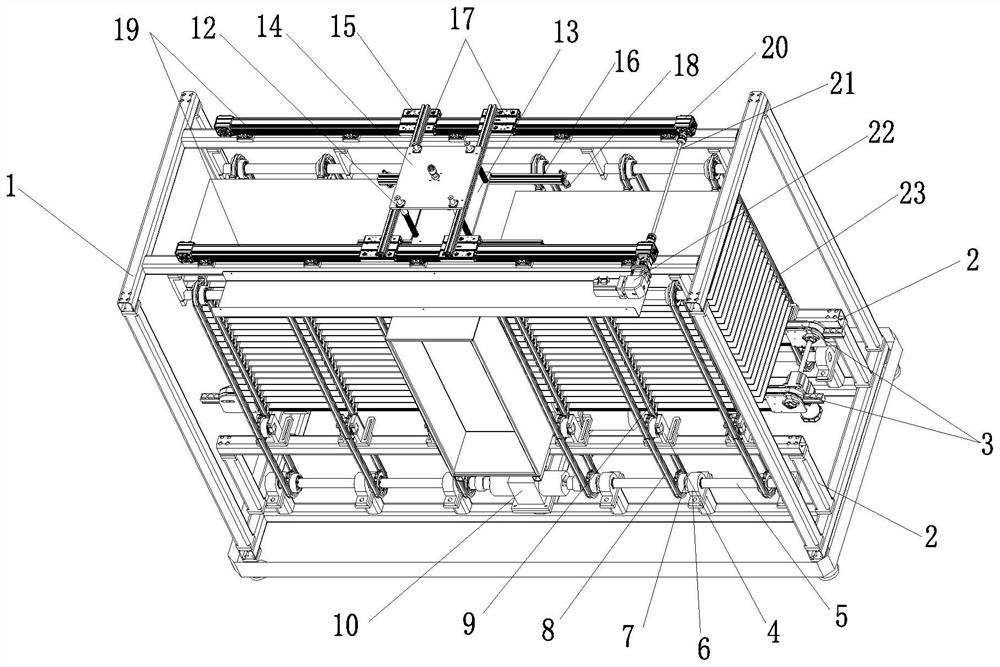

[0022] Such as Figure 1-3 As shown, a high-efficiency caching curing machine for perovskite solar photovoltaic production includes a rectangular frame 1, a belt conveyor 3, a deceleration and reversing drive mechanism, a chain caching mechanism, a vacuum suction mechanism, a transplanting mechanism and a U Frame 2, the top of the rectangular frame 1 is provided with a transplanting mechanism, and the transplanting mechanism is connected with the vacuum suction lifting mechanism, and the two belt conveyors 3 are arranged in parallel on the top between the two U-shaped frames 2, And the middle part between the two U-shaped frames 2 is provided with a deceleration and reversing drive mechanism. The chain type buffer mechanism is arranged in the rectangular frame 1, and the chain type lifting buffer mechanism is divided into an ascending assembly and a descending assembly. The rectangular machine Four transmission rods 5 are evenly distributed in a matrix in the space on both sid...

Embodiment 2

[0026] The chain buffer mechanism includes an upper gear 4, a lower gear 7, a transmission chain 8 and a supporting block group 9, three lower gears 7 of the same group are equidistantly installed on the transmission rod 5, and six upper gears 4 of the same group Equidistantly installed on the top surface of the U-shaped frame 2, two lower gears 7 located on the same set of vertical planes and one upper gear 4 are connected through a transmission chain 8, and the transmission chain 8 is equidistantly provided with supporting block groups 9. A glass plate 23 is arranged between the four supporting blocks on the same horizontal plane.

[0027] The advantage of this place is that a three-dimensional buffer space can be formed by vertically distributing four transmission chains 8 in the same group, and several glass plates are formed between the supporting block groups 9 on the four transmission chains 8 23 supports put space, has improved the quantity that glass plate 23 is loade...

Embodiment 3

[0029] The vacuum suction mechanism includes a buffer rod 12, a transplanting hanging plate 13, an upper hanging plate 14, a load connecting rod 15, a suction cup mounting rod 16 and a pneumatic suction cup 18, and the bottom ends of the four buffer rods 12 are installed on the top of the transplanting hanging plate 13 respectively. At the four corners, and the buffer rod 12 passes through the corresponding part of the upper hanging plate 14, the top of the buffer rod 12 is provided with a limit block structure, and the front and rear ends of the bottom of the transplanting hanging plate 13 are equipped with suction cup installation rods 16, and the bottom of the suction cup installation rods 16 are equidistantly installed There are a plurality of pneumatic suction cups 18, and the both sides of the hanging plate 14 bottom are equipped with load-bearing connecting rods 15.

[0030] The advantage of this place is: using the four buffer rods 12 equipped with return springs, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com