Positive electrode material, preparation method and application thereof, and lithium ion battery

A cathode material, lithium source technology, applied in the direction of positive electrode, battery electrode, secondary battery, etc., can solve the problem of lithium-ion battery cycle, capacity, rate can not meet the needs and other problems, achieve suitable for large-scale industrial production, reduce interface Impedance, the effect of improving the magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The second aspect of the present invention provides a method for preparing a positive electrode material, characterized in that the preparation method comprises the following steps:

[0072] S1. The nickel-cobalt-manganese hydroxide precursor, lithium source and optional dopant M are first mixed to obtain a mixture I, and the mixture I is calcined, crushed, and sieved in an air or oxygen atmosphere , to obtain the positive electrode material matrix;

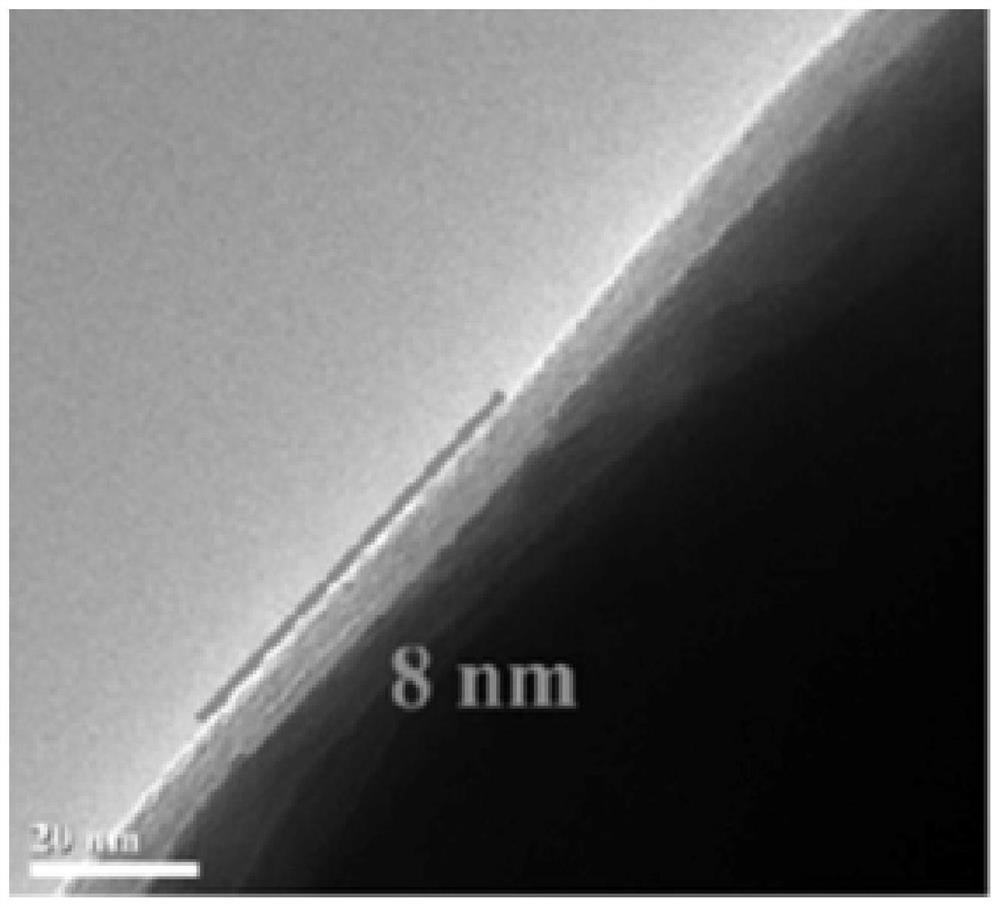

[0073] S2, titanium source, niobium source, optional M' source, optional M "source and optional G source, according to n(Ti):n(M'):n(Nb):n(M" ):n(G)=(1-α):α:(γ-β):β:δ molar ratio is mixed for the second time to obtain the mixture II, and in the air atmosphere, the mixture II is sintered and crushed, Get the covering material;

[0074] S3. Perform a third mixing of the positive electrode material matrix and the coating material to obtain a mixture III, and perform heat treatment on the mixture III to obtain the positive e...

preparation example 1

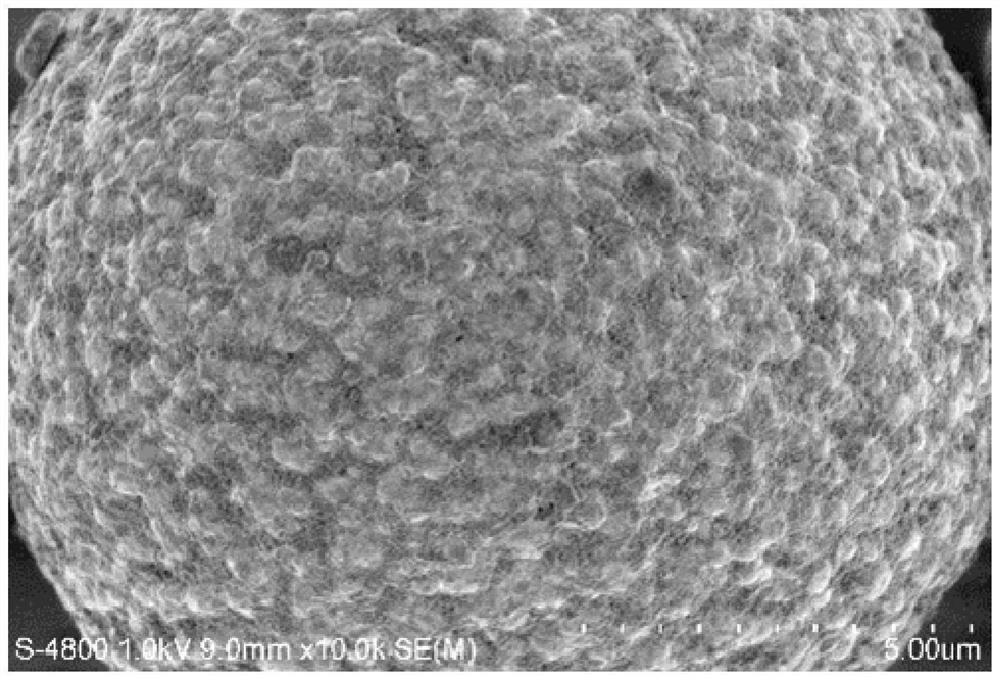

[0180] Nickel cobalt manganese hydroxide precursor P1

[0181] (1) Prepare a 2mol / L mixed salt solution of nickel sulfate, cobalt sulfate, and manganese sulfate according to the molar ratio of Ni, Co, and Mn elements of 90:5:5. Prepare 7mol / L sodium hydroxide alkali solution; prepare 6mol / L ammonia water complexing agent solution.

[0182] (2) The mixed salt solution, alkali solution, and ammonia water complexing agent solution are continuously added into the agitator in a co-current manner for reaction, and the stirring speed is 120 rpm. Simultaneously control the mixed salt solution feed flow rate to 40L / h, the alkali solution feed flow rate to 20L / h, the complexing agent solution feed flow rate to 6L / h, the pH to 11.5, the temperature to 60°C, and the reaction for 30h. When the reaction is completed, the obtained nickel-cobalt-manganese hydroxide slurry is subjected to solid-liquid separation and washing, the filter cake is dried at 100°C for 10 hours and then sieved, and ...

preparation example 2

[0184] Nickel cobalt manganese hydroxide precursor P2

[0185] (1) Prepare 2mol / L mixed salt solution of nickel sulfate, cobalt sulfate, manganese sulfate and zirconium nitrate according to the molar ratio of Ni, Co, Mn, and Zr elements of 60:20:19:1. Prepare 7mol / L sodium hydroxide alkali solution; prepare 6mol / L ammonia water complexing agent solution.

[0186] (2) The mixed salt solution, alkali solution, and ammonia complexing agent solution are continuously added into the agitator in a co-current manner for reaction, and the stirring speed is 100 rpm. At the same time, the mixed salt solution inlet flow rate is controlled to be 35L / h, the alkali solution inlet flow rate is 18L / h, the complexing agent solution inlet flow rate is 6L / h, the pH is controlled to be 11.6, the temperature is 60°C, and the reaction is 38h. When the reaction is completed, the obtained nickel-cobalt-manganese hydroxide slurry is subjected to solid-liquid separation and washing, the filter cake is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com