High-temperature-resistant bismaleimide resin fiber reinforced nonmetal oil pipe and manufacturing method thereof

A dual-horse resin and fiber-reinforced technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of being unable to meet the environmental requirements of high temperature, high pressure, harsh corrosion conditions, high operating costs, and the weight of oil pipes, etc., to achieve reduction Suspended weight of the tubing and difficulty of on-site construction operations, solution to high-temperature corrosion bottlenecks, and improved torsional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

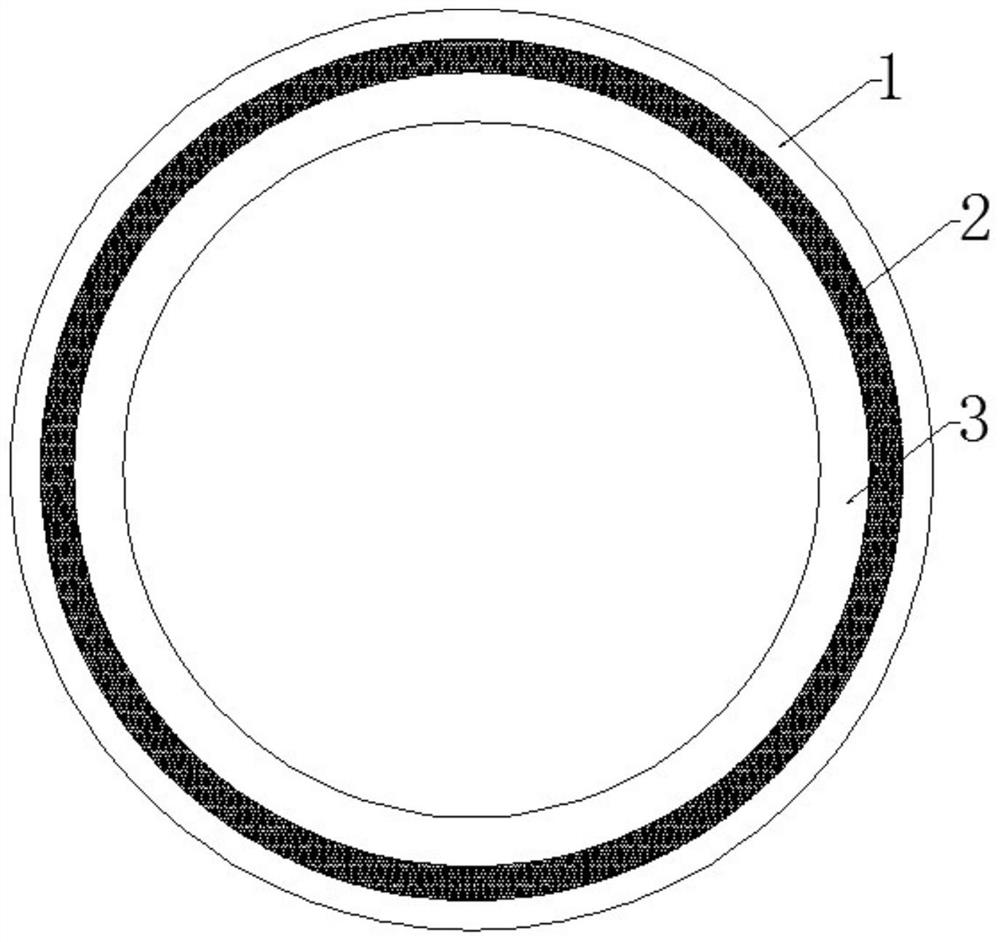

[0038] Such as figure 1As shown, a high-temperature-resistant Shuangma resin fiber reinforced non-metallic oil pipe includes a resin-based composite material inner layer 3, a long fiber winding layer 2, and an outer resin layer 1 from the inside to the outside. The resin-based composite material inner layer 3 It is a double-horse resin material mixed with chopped carbon fibers, and the long-fiber winding layer 2 is a continuous carbon fiber tape wound on the inner resin layer according to certain rules, and the outer resin layer 1 is made of double-horse resin material, and the outer resin layer will be Filament wrap for complete wrap. The inner and outer layers of the oil pipe are made of Shuangma resin, which provides the oil pipe with low density, corrosion resistance, and high temperature resistance; the fiber tape provides better tensile performance, and better adapts to the high-pressure environment inside and outside the oil pipe.

[0039] According to the above soluti...

Embodiment 2

[0048] Such as Figure 4 A method for making a high-temperature-resistant dual-horse resin fiber-reinforced non-metallic oil pipe according to the above-mentioned embodiment includes the following steps:

[0049] S1: Prepare Shuangma resin-chopped carbon fiber raw materials by pre-mixing method, use molds, and make base pipes by extrusion molding process;

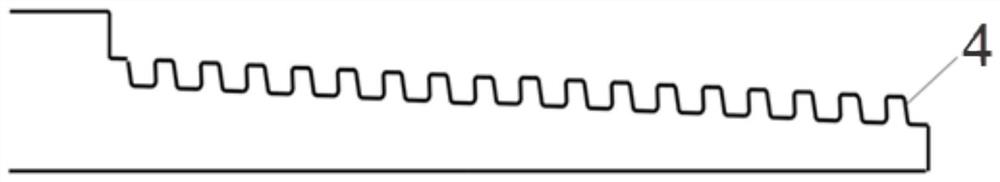

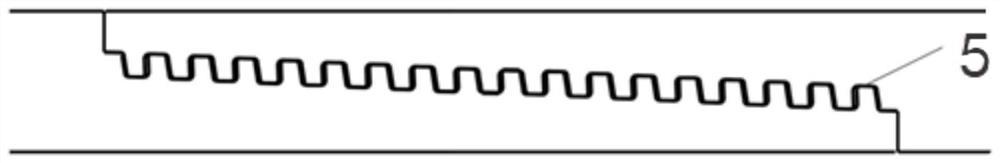

[0050] S2: After the fiber tape is pre-impregnated with Shuangma resin, it is directly wound on the base pipe, one layer of the fiber is wound at ±10°, and one layer of the fiber is wound at ±60° and ±85°, and the fiber needs to be wound to the pipe end;

[0051] S3: external dip coating with Shuangma resin;

[0052] S4: The base pipe wrapped with the pre-impregnated Shuangma resin carbon fiber tape is cured and formed by heating.

[0053] Laying at ±10° can improve the tensile performance of the material, laying at ±60° can improve the torsional performance of the material, and laying at ±85 can improve the internal pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com