Anti-oxidation bonding layer and preparation method of thermal barrier coating of anti-oxidation bonding layer

A technology of thermal barrier coating and bonding layer, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., and can solve the problem of uneven structure, poor anti-stripping ability of oxide layer, and affecting the service life of the coating, etc. problems, to achieve the effect of long service life, uniform structure and high working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

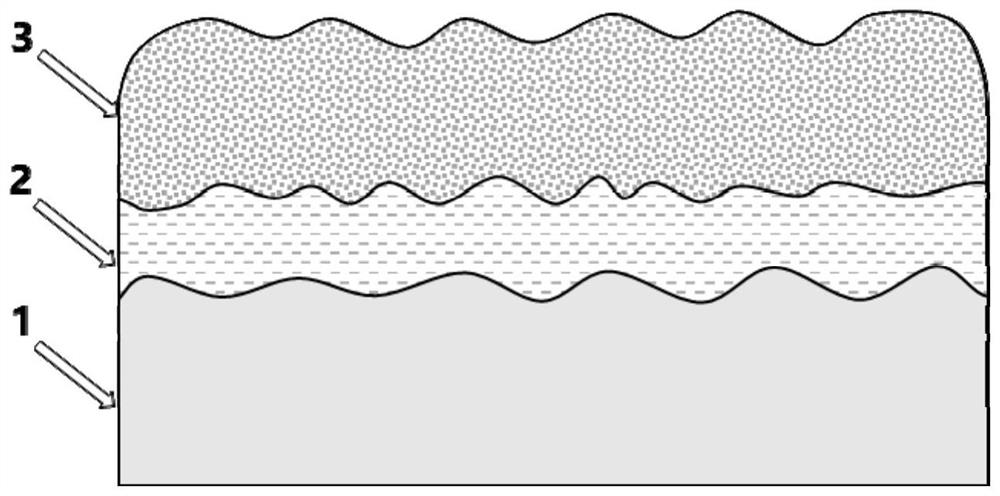

Method used

Image

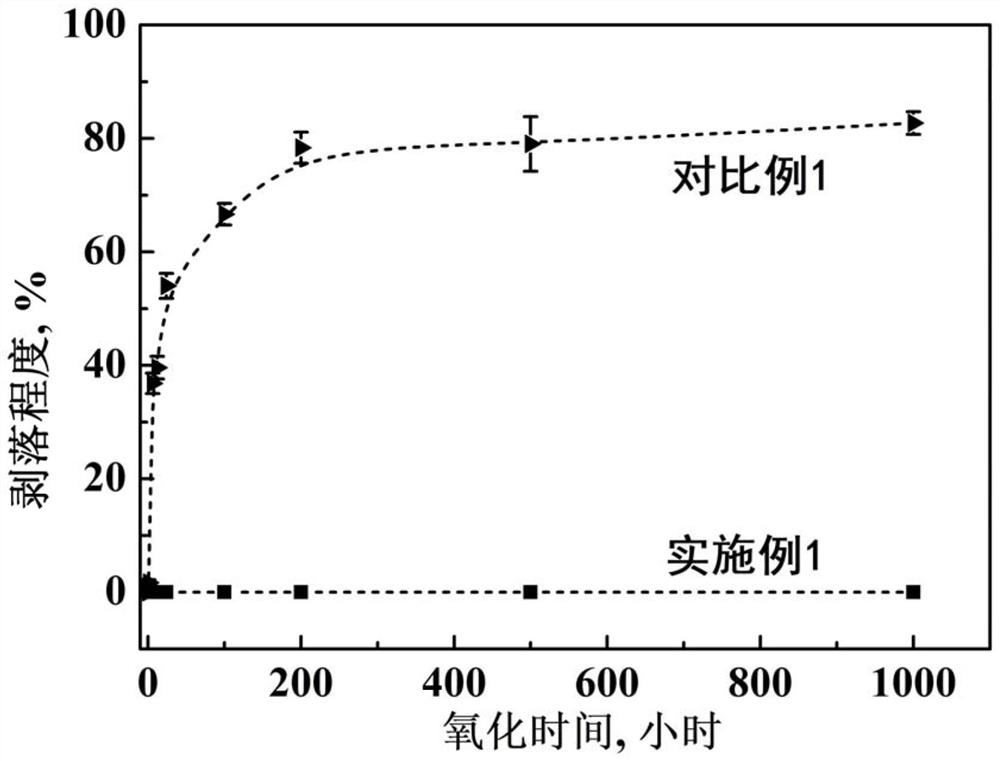

Examples

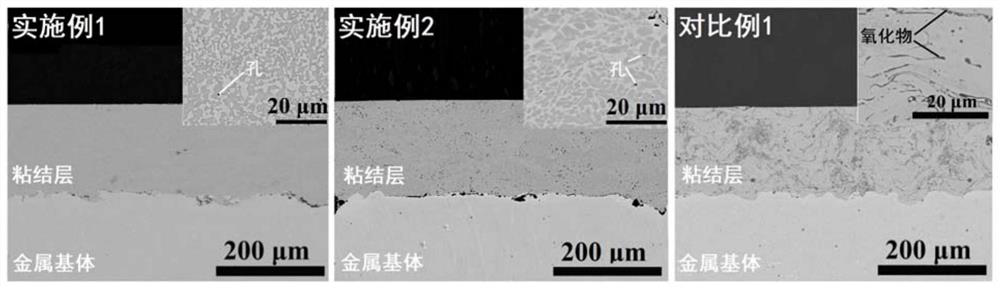

Embodiment 1

[0027] (1) Firstly, ultrasonically clean the superalloy substrate with acetone and alcohol in sequence. After drying, use Al with a particle size of 60 mesh 2 o 3 , cold sandblasting the substrate. The sandblasting pressure is 0.5MPa, and the surface roughness Ra after sandblasting is 18±5μm.

[0028] (2) When using high-speed gas flame spraying, first preheat the metal substrate 3 times, the temperature of the metal substrate is controlled below 200°C, the distance between the spray gun and the metal bonding layer is 180mm, and the moving speed of the spray gun is 1000mm / s. The powder feeding speed is 3r / min, the propane pressure is 85PSI, the air pressure is 90PSI, the hydrogen pressure is 20PSI, and the nitrogen pressure is 20PSI.

[0029] (3) In order to obtain a metal bonding layer with uniform surface roughness, the bonding layer is treated by thermal sandblasting. Sandblasting particles are 180 mesh Al 2 o 3 , the distance between the spray gun and the metal bondi...

Embodiment 2

[0034] (1) Firstly, ultrasonically clean the superalloy substrate with acetone and alcohol in sequence. After drying, use Al with a particle size of 60 mesh 2 o 3 , cold sandblasting the substrate. The sandblasting pressure is 0.8MPa, and the surface roughness Ra after sandblasting is 19±4μm.

[0035] (2) When using high-speed gas flame spraying, first preheat the metal substrate 3 times, the temperature of the metal substrate is controlled below 200°C, the distance between the spray gun and the metal bonding layer is 200mm, and the moving speed of the spray gun is 1000mm / s. The powder feeding speed is 5r / min, the propane pressure is 87PSI, the air pressure is 92PSI, the hydrogen pressure is 20PSI, and the nitrogen pressure is 20PSI.

[0036] (3) In order to obtain a metal bonding layer with uniform surface roughness, the bonding layer is treated by thermal sandblasting. Sandblasting particles are 200 mesh Al 2 o 3 , the distance between the spray gun and the metal bondi...

Embodiment 3

[0040] (1) Firstly, ultrasonically clean the superalloy substrate with acetone and alcohol in sequence. After drying, use Al with a particle size of 60 mesh 2 o 3 , cold sandblasting the substrate. The sandblasting pressure is 0.8MPa, and the surface roughness Ra after sandblasting is 19±4μm.

[0041] (2) When using high-speed gas flame spraying, first preheat the metal substrate 3 times, the temperature of the metal substrate is controlled below 200°C, the distance between the spray gun and the metal bonding layer is 180mm, and the moving speed of the spray gun is 1000mm / s. The powder feeding speed is 3r / min, the propane pressure is 85PSI, the air pressure is 90PSI, the hydrogen pressure is 20PSI, and the nitrogen pressure is 20PSI.

[0042] (3) In order to obtain a metal bonding layer with uniform surface roughness, the bonding layer is treated by thermal sandblasting. Sandblasting particles are 220 mesh Al 2 o 3 , the distance between the spray gun and the metal bondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com