Catalytic cracking multifunctional metal trapping agent and preparation method thereof

A metal trapping agent, multi-functional technology, applied in the direction of catalytic cracking, catalyst protection, chemical instruments and methods, etc., can solve the problems of poor distribution of conversion products, low activity of metal trapping agents, etc., to reduce coke yield, Good metal trapping effect, the effect of improving catalytic cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

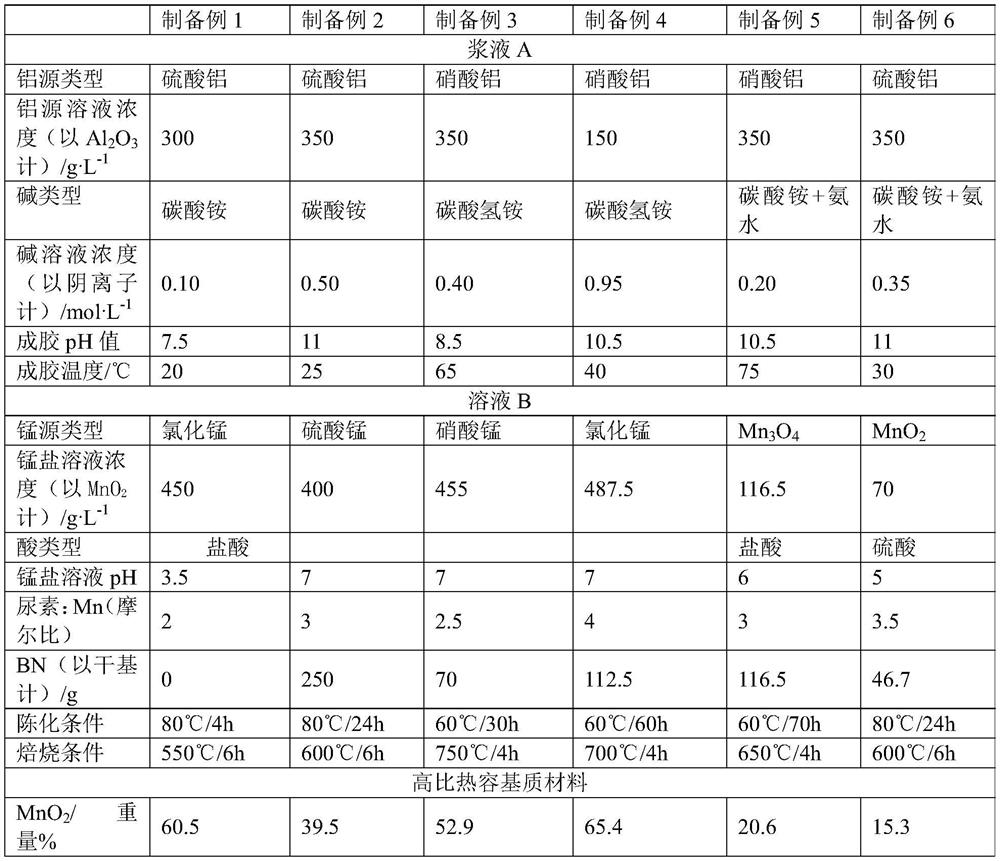

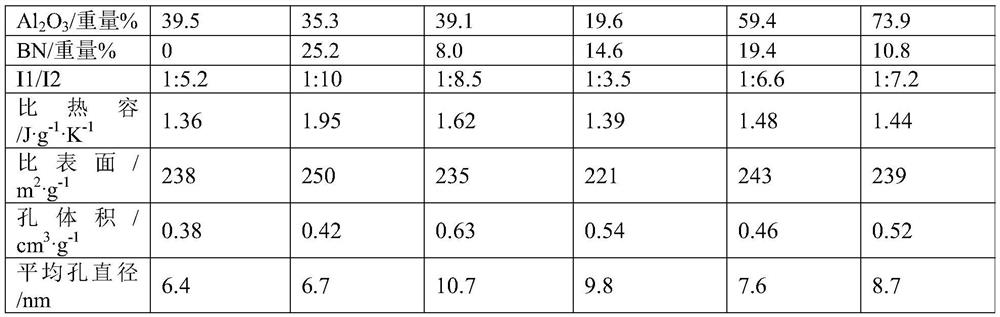

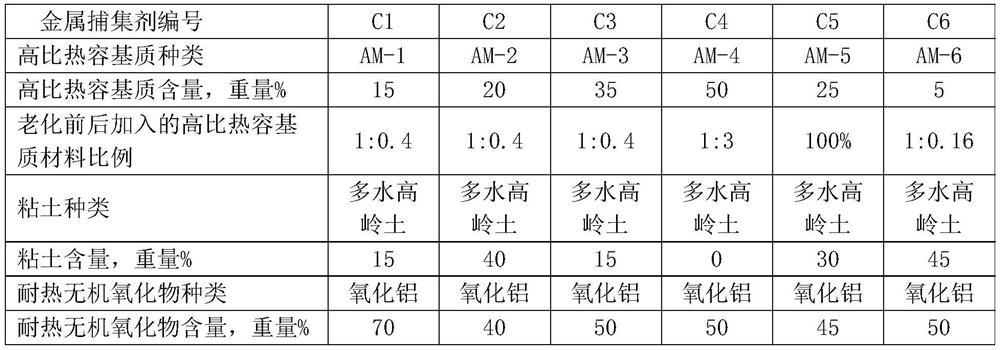

[0045] In the metal trapping agent provided by the present invention, the high specific heat capacity matrix material, in the first embodiment, does not contain boron compounds, based on the weight of the high specific heat capacity matrix material, the high specific heat capacity matrix material contains Al 2 o 3 5-95% by weight of alumina and MnO 2 5-95% by weight of manganese oxide, for example, the high specific heat capacity matrix material is mainly composed of 15-70% by weight or 20-65% by weight or 30-61% by weight of manganese oxide and 30-85% by weight or 35- 80% by weight or 39-70% by weight of alumina. The specific surface area of the high specific heat capacity matrix material can be 180-300m 2 g -1 For example 200-250m 2 g -1 or 220-245m 2 g -1 ; The pore volume of the high specific heat capacity matrix material is 0.35-0.75 such as 0.4-0.65cm 3 g -1 ; The average pore diameter of the high specific heat capacity matrix material is 5-13nm, such as 6-11n...

preparation example 1

[0100] This example illustrates the preparation of a high specific heat capacity matrix material.

[0101] Concentration 300gAl 2 o 3 / L Al 2 (SO 4 ) 3 solution with CO 3 2- The ammonium carbonate solution with a concentration of 0.10 mol / L was mixed at 20° C. to form a colloid, and the obtained colloid had a pH value of 7.5, and a slurry A was obtained. To a concentration of 450gMnO 2 / L MnCl 2 Add hydrochloric acid to the solution to control the pH value = 3.5, then add urea to the solution, the molar ratio of urea to manganese ions is 2, and stir at room temperature for 30 minutes to obtain solution B. Add solution B to slurry A, stir and age at 80°C for 4h, wait until the temperature of the system drops to room temperature, rinse with deionized water until the washed water is neutral, dry at 120°C for 12h to obtain the matrix material precursor, and then Calcined at 550°C for 6 hours, and cooled to room temperature with the furnace to obtain the matrix material wi...

preparation example 2-4

[0104] Prepare high specific heat capacity matrix materials AM-2 to AM-4 according to the method of Preparation Example 1, the difference is that the raw material ratio, preparation condition parameters, elemental composition of the product, specific heat capacity, specific surface area, pore volume and average pore diameter are listed in Table 1 , wherein the solution B is added to the slurry A, and then boron nitride is added, and then the aging is carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com