Method for preparing rare earth carbonate from ionic rare earth ore

A technology of ionic rare earth ore and rare earth carbonate, which is applied in the field of rare earth metallurgy, can solve the problems of complex preparation process and high condition requirements, and achieve the effect of low separation cost, high purity and less loss of rare earth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

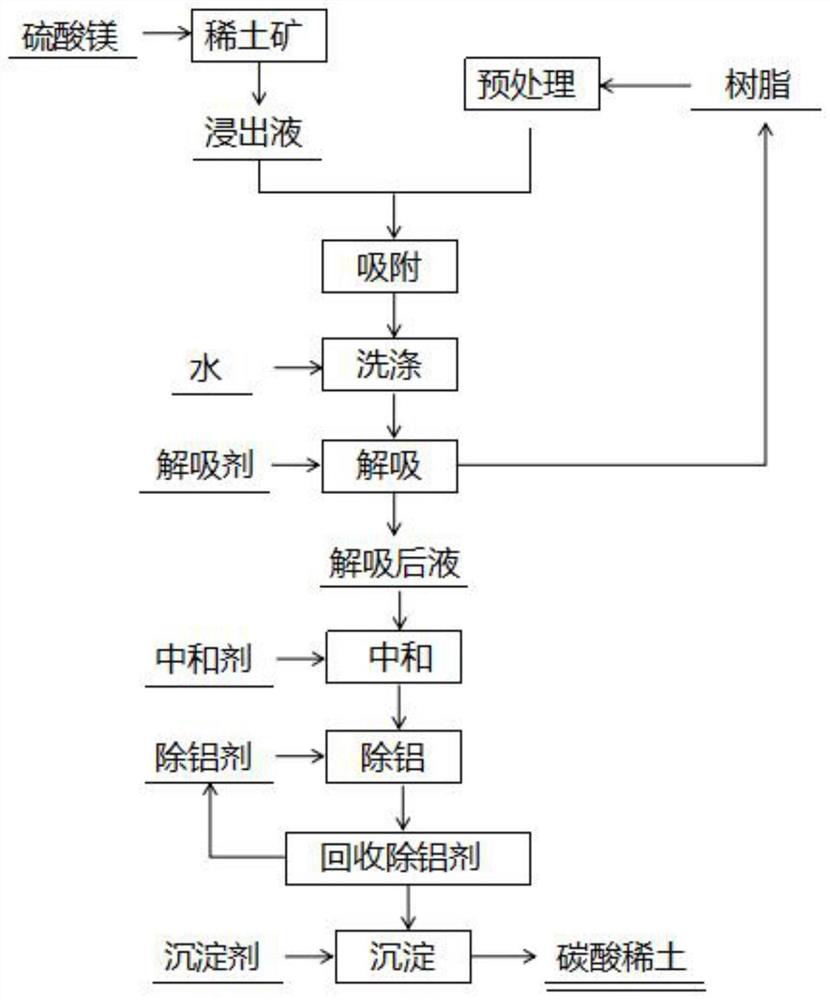

Method used

Image

Examples

Embodiment 1

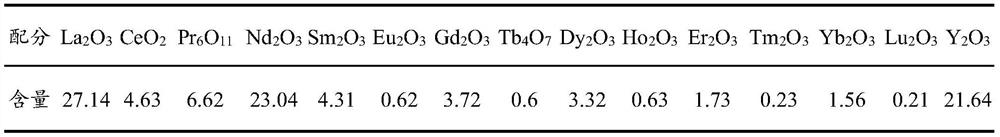

[0076] Table 1 is the material composition of ionic rare earth ores.

[0077] Table 1 Rare Earth Element Distribution Table of Ionic Rare Earth Ore Unit: wt%

[0078]

[0079] The ionic RE content of the ionic rare earth mineral is 0.0396wt%.

[0080] ore leaching

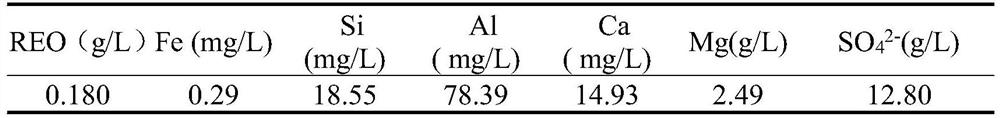

[0081] According to the solid-liquid ratio of 1kg:0.66L, prepare a magnesium sulfate leaching agent with a mass fraction of 2%, adjust the pH value to 5.0, add ionic rare earth ore to leaching the ore, take the leaching solution, and add top water after the leaching agent has run out Wash until the lotion does not contain rare earths, and the leaching solutions are combined to obtain the ionic rare earth leaching solution. The ingredients of the leachate are shown in Table 2:

[0082] Table 2 Leaching liquid composition

[0083]

[0084] Extraction Resin Pretreatment

[0085] The extraction resin used is P507, according to the extraction resin: hydrochloric acid = 1:1 (volume ratio), soak in hydrochloric...

Embodiment 2

[0104] Table 4 is the distribution table of rare earth elements in ionic rare earth ores.

[0105] Table 4 Distribution table of rare earth elements in ionic rare earth ores Unit: wt%

[0106]

[0107] The ionic RE content of the ionic rare earth mineral is 0.110wt%.

[0108] ore leaching

[0109] According to the solid-liquid ratio of 1kg:0.55L, prepare a magnesium sulfate leaching agent with a mass fraction of 3%, adjust the pH value to 4.5, add the ionic rare earth ore to leaching the ore, take the leachate, and add top water after the leaching agent has run out. Wash until the lotion does not contain rare earths, and the leaching solutions are combined to obtain the ionic rare earth leaching solution. The ingredients of the leachate are shown in Table 5:

[0110] Table 5 Leaching solution composition

[0111]

[0112] Extraction Resin Pretreatment

[0113] The extraction resin used is P507, according to the extraction resin: hydrochloric acid = 1:1 (volume ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com