Hydrocracking aromatic polymer and method for preparing aromatic hydrocarbon from heavy aromatic hydrocarbon

A technology of aromatic polymers and hydrocracking, which is applied in the preparation of liquid hydrocarbon mixtures, cracking of hydrocarbon oils, and treatment of hydrocarbon oils, etc., and can solve the problems of increasing the cost of catalyst production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Test material: polymer containing aromatic ring: polystyrene; polymer mass containing aromatic ring: 0.1 g; solvent: dodecane; solvent mass: 2 g; substrate concentration: 5%;

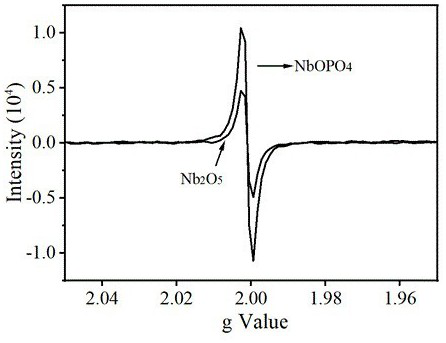

[0035] Catalyst: niobium oxide prepared by hydrothermal method, catalyst mass 0.1 g;

[0036] Test conditions: batch reactor; hydrogen pressure: 0.5 MPa; reaction temperature: 280°C;

[0037] Reaction time: 12 hours;

[0038] Test method: crush 0.1 g polystyrene in a pulverizer until it can pass through a 40-mesh sieve, and disperse the crushed polystyrene in 2 g dodecane, and then put the dispersion and 0.1 g niobium oxide into the In a 50 ml stainless steel autoclave, seal it, fill it with 0.5 MPa hydrogen, heat up to the required temperature of 280°C under rapid stirring, stop the reaction after 12 hours, cool, centrifuge the catalyst, and rectify the supernatant to obtain the product benzene, Ethylbenzene, cumene, indene and substituted indene, the molar yield of benzene can reach 40%.

Embodiment 2

[0040] The only difference from Example 1 is that the catalyst is niobium phosphate.

Embodiment 3

[0042] The only difference from Example 1 is that the catalyst is niobium silicon mixed oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com