High-strength stainless steel powder for SLM, preparation method and printing process of high-strength stainless steel powder

A stainless steel, high-strength technology, applied in the direction of additive processing, metal processing equipment, transportation and packaging, etc., can solve the problems that cannot meet the high strength, high plasticity and toughness of SLM printed stainless steel parts, high gas content and high oxygen content, and achieve improved mechanics and Effects of processability, strength improvement, and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing high-strength stainless steel powder for SLM, comprising the following steps:

[0044] Step 1, adopting the method of vacuum induction melting + vacuum consumable remelting to prepare master alloy;

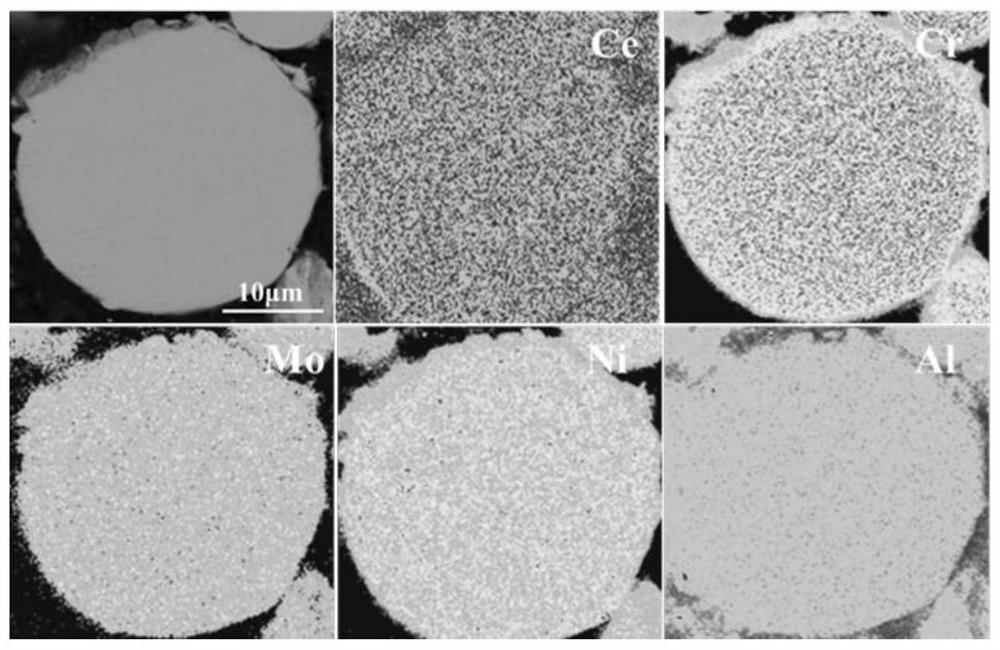

[0045] Specifically, step 1 includes: using pure carbon, silicon, manganese, chromium, nickel, molybdenum, and aluminum to prepare a master alloy by vacuum induction melting and vacuum self-consumption remelting, the chemical composition of the master alloy is: C≤0.04% , Si≤0.05%, Mn≤0.05%, Cr: 12.5~13.5%, Ni: 7.5~8.5%, Mo: 2.0~2.5%, Al: 1.0~1.15%, P≤0.005%, S≤0.002%, O ≤0.001%, N≤0.002%, and the balance is Fe and unavoidable impurities. Then the master alloy is forged into a 30×40×500 mm alloy block, and the oxide skin and dirt on the surface of the alloy block are removed by a grinder, and then used for gas atomization powder production.

[0046] Step 2. Vacuum smelting gas atomization milling (VIGA);

[0047] ...

Embodiment 1

[0073] 1. Preparation of stainless steel powder:

[0074] Step 1, adopting the method of vacuum induction melting + vacuum consumable remelting to prepare master alloy;

[0075] The master alloy is prepared by vacuum induction melting and vacuum consumable remelting with pure carbon, silicon, manganese, chromium, nickel, molybdenum and aluminum. The master alloy is forged into a 30×40×500mm alloy block, and the oxide skin and dirt on the surface of the alloy block are removed by a grinder, and then used for gas atomization powder production.

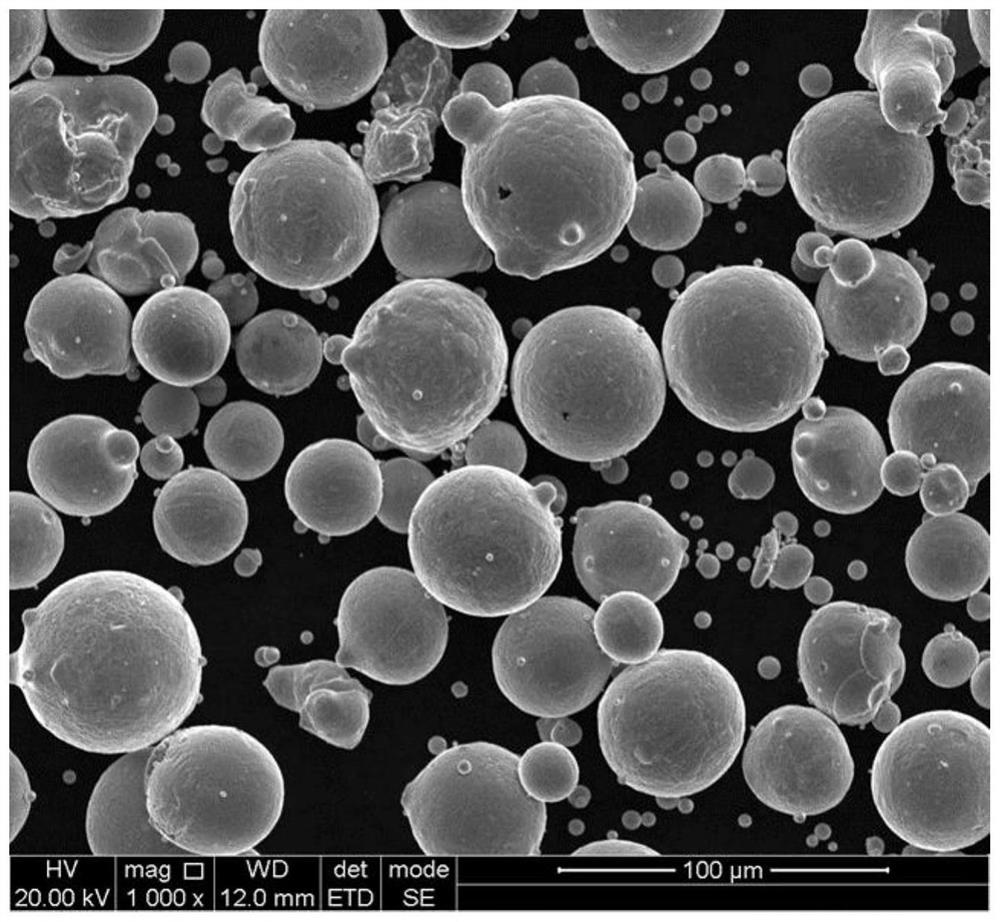

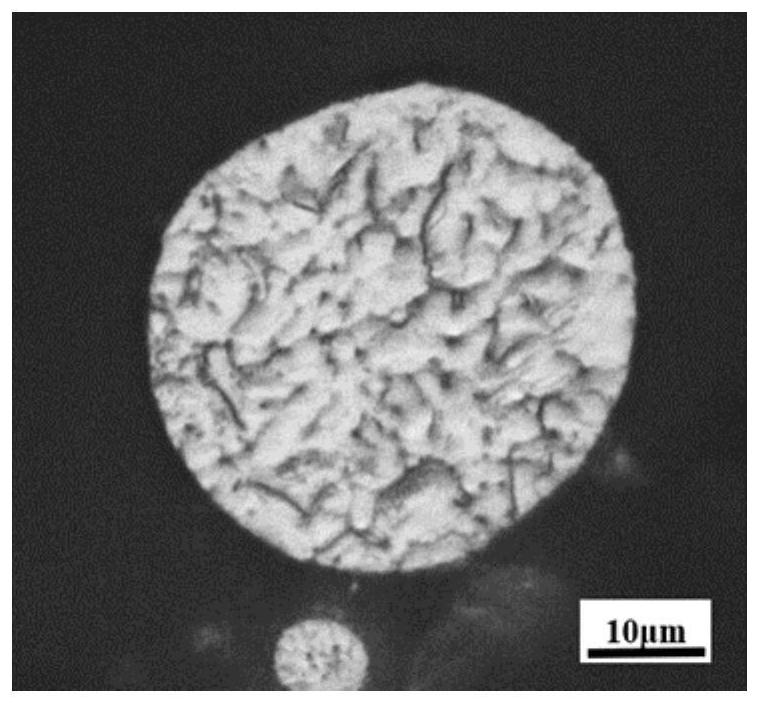

[0076] Step 2, Vacuum Air Atomization Milling (VIGA);

[0077] Weigh 30kg master alloy bulk material and place it in the smelting furnace of the vacuum air atomization pulverization equipment, and evacuate the atomization chamber and the smelting chamber to vacuum. During smelting, the power of the induction furnace is 1400kW, until the base metal is completely melted into molten steel, and block rare earth Ce is added to the molten st...

Embodiment 2

[0086] 1. Preparation of stainless steel powder:

[0087] Step 1, adopting the method of vacuum induction melting + vacuum consumable remelting to prepare master alloy;

[0088] The master alloy is prepared by vacuum induction melting and vacuum consumable remelting with pure carbon, silicon, manganese, chromium, nickel, molybdenum and aluminum. The master alloy is forged into a 30×40×500mm alloy block, and the oxide skin and dirt on the surface of the alloy block are removed by a grinder, and then used for gas atomization powder production.

[0089] Step 2, Vacuum Air Atomization Milling (VIGA);

[0090] Weigh 30kg master alloy bulk material and place it in the smelting furnace of the vacuum air atomization pulverization equipment, and evacuate the atomization chamber and the smelting chamber to vacuum. During smelting, the power of the induction furnace is 1400kW, until the base metal is completely melted into molten steel, and block rare earth Ce is added to the molten st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com