High-heat-resistance solar cell and preparation method thereof

A solar cell and high heat-resistant technology, applied in the field of solar cells, can solve the problems of affecting the light receiving efficiency of the semiconductor layer, reducing the efficiency of photoelectric energy conversion, and reducing the light transmittance of the adhesive film, so as to prevent cracks or stains, Improve dispersibility and increase viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

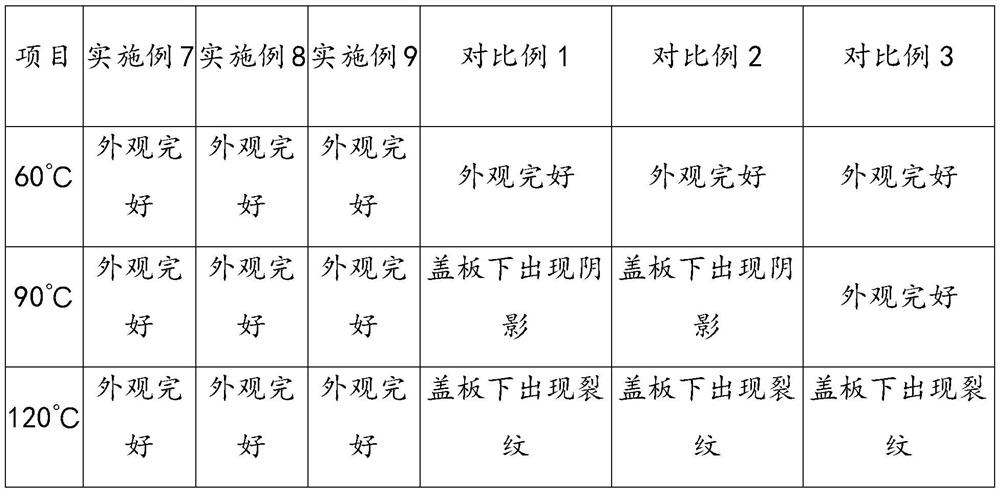

Examples

Embodiment 1

[0022] Prepare the film, comprising the steps of:

[0023] Mix 2g of diisooctyl phthalate, 1.2g of polyamic acid, 0.5g of vinyltrimethoxysilane and 1g of pentaerythritol tetrakis (2-cyano-3,3-diphenylacrylate) with a high-speed mixer, To obtain the additive composition, preheat at 70°C;

[0024] Set the temperature of the feeding section of the twin-screw extruder to 120°C, the melting section to 160°C, and the die opening temperature to 170°C; crush 100g of PVB resin into particles with a diameter of 0.5cm, and dry it at 45°C for 3 hours. Mix the dried PVB resin granules and 3 g of the preheated additive composition with a high-speed mixer for 30 minutes, melt extrude and granulate with a twin-screw extruder to obtain PVB plastic granules;

[0025] Preheat the PVB plastic granules at 80°C for 45 minutes, then use a thermocompression molding machine to pressurize and exhaust at 145°C and keep the pressure for 3 minutes, and mold the preheated PVB plastic granules into a 0.4mm...

Embodiment 2

[0027] Prepare the film, comprising the steps of:

[0028] Put 2.5g of di-isooctyl phthalate, 1.6g of polyamic acid, 0.6g of vinyltrimethoxysilane and 1.2g of pentaerythritol tetrakis (2-cyano-3,3-diphenylacrylate) in a high-speed mixer Mix to obtain the additive composition, and preheat at 75°C;

[0029] Set the temperature of the feeding section of the twin-screw extruder to 125°C, the melting section to 170°C, and the die opening temperature to 175°C; crush 100g of PVB resin into particles with a diameter of 1cm, dry it at 48°C for 4 hours, and dry the The dried PVB resin granules and the preheated additive composition were mixed with a high-speed mixer for 45 minutes, melted and extruded with a twin-screw extruder and pelletized to obtain PVB plastic granules;

[0030] Preheat the PVB plastic granules at 85°C for 50 minutes, then use a thermocompression molding machine to pressurize and exhaust at 150°C and then keep the pressure for 4 minutes, and mold the preheated PVB ...

Embodiment 3

[0032] Prepare the film, comprising the steps of:

[0033] Mix 3g of diisooctyl phthalate, 2g of polyamic acid, 0.8g of vinyltriethoxysilane and 1.5g of pentaerythritol tetrakis(2-cyano-3,3-diphenylacrylate) with a high-speed mixer , to obtain the additive composition, preheating at 80°C;

[0034] Set the temperature of the feeding section of the twin-screw extruder to 130°C, the melting section to 180°C, and the die opening temperature to 180°C; crush 100g of PVB resin into particles with a diameter of 2cm, dry it at 50°C for 5h, and The dried PVB resin particles and the preheated additive composition were mixed with a high-speed mixer for 60 minutes, melted and extruded with a twin-screw extruder and pelletized to obtain PVB plastic particles;

[0035] Preheat the PVB plastic granules at 90°C for 60 minutes, then use a thermocompression molding machine to pressurize and exhaust at 150°C and keep the pressure for 5 minutes, mold the preheated PVB plastic granules into a 1mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com