Inorganic perovskite quantum dot diffusion plate and preparation method thereof

A technology of quantum dots and inorganic calcium, applied in the field of inorganic perovskite quantum dot diffusion plate and its preparation, can solve the problems of occupying quantum dot diffusion plate, large half width, high cost, etc., saving time, manpower and material resources, Good color performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

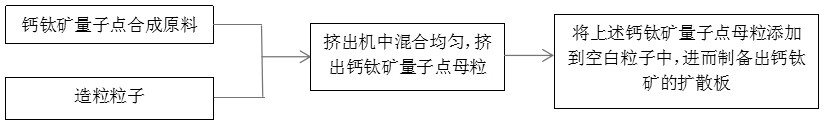

[0030] Please refer to figure 1 , the present embodiment also provides a method for preparing an inorganic perovskite quantum dot diffusion plate, comprising the following steps:

[0031] Step S1: weighing the material and granulated particles of high-temperature synthetic perovskite according to the preset mass ratio;

[0032] Step S2: first mix the perovskite material and the granulated particles;

[0033] Step S3: putting the mixed granulated particles and the perovskite mineral material into the feed hopper of the extruder;

[0034] Step S4: the extruder melts, reacts, extrudes, draws the wire, cuts pellets, forms the perovskite quantum dot master batch;

[0035] Step S5: adding the above-mentioned perovskite quantum dot masterbatch to blank particles, and then preparing a diffusion plate of perovskite quantum dots.

Embodiment 1

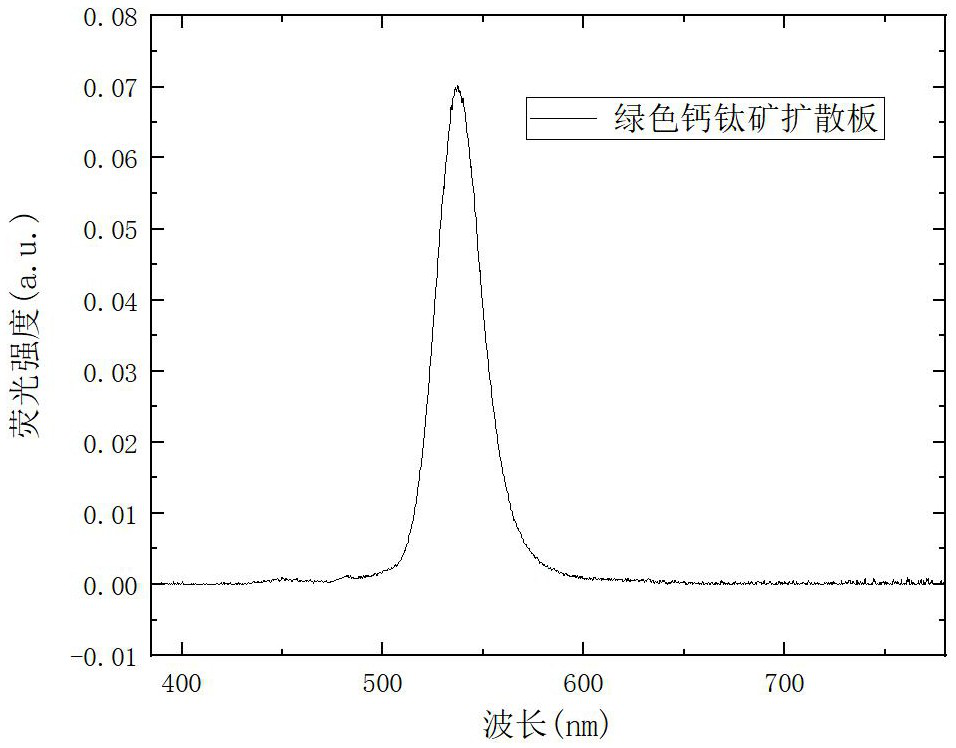

[0037] This embodiment provides a method for forming a green perovskite quantum dot polystyrene diffusion plate in situ, the steps are as follows:

[0038] (1) Weigh 4.46gPbBr 2 , 1.22g CsCO 3 , 30mL oleic acid, 30mL oleylamine; weigh 724.56g of polystyrene particles.

[0039] (2) Mix the above materials with polystyrene particles evenly, and add them to the feeding funnel of the extruder. The feed temperature is 220°C, and the discharge temperature is 200°C.

[0040] (3) Mixing and extruding with an extruder, water cooling, wire drawing, and pelletizing to obtain green perovskite quantum dot color masterbatch.

[0041] (4) Weigh 62.5g of silica diffusion particles, 187.5g of green perovskite quantum dot color masterbatch, and 1000g of polystyrene particles

[0042] (5) Mix the particles weighed in (4) and put them into the feeding funnel of the extruder. The feeding temperature is 220°C, and the discharging temperature is 200°C. After cooling, the green perovskite quantu...

Embodiment 2

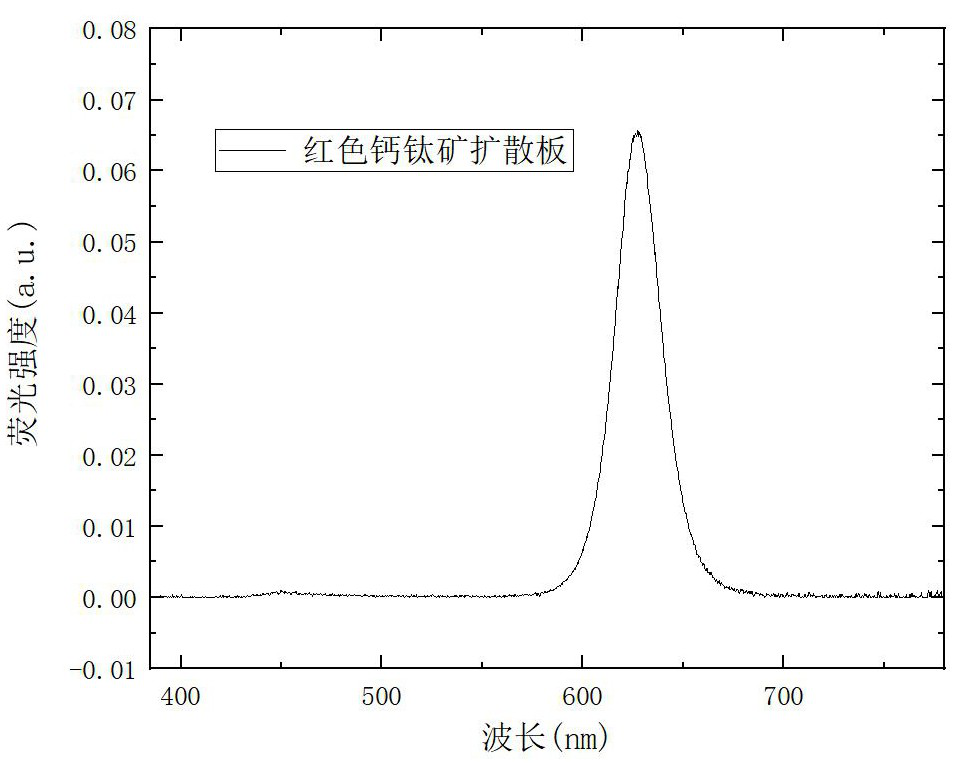

[0044] This embodiment provides a method for forming red perovskite quantum dot polystyrene diffusion plate in situ, the steps are as follows:

[0045] (1) Weigh 3.69gPbI 2 , 1.46gPbBr 2 , 1.22g CsCO 3 , 30mL oleic acid, 30mL oleylamine; weigh 724.56g of polystyrene particles.

[0046] (2) Mix the above materials with polystyrene particles evenly, and add them to the feeding funnel of the extruder. The feed temperature is 220°C, and the discharge temperature is 200°C.

[0047] (3) Mixing and extruding with an extruder, water cooling, wire drawing, and pelletizing to obtain red perovskite quantum dot masterbatch.

[0048] (4) Weigh 62.5g silica diffusion particles, 187.5 red perovskite quantum dot masterbatch, 1000g polystyrene particles

[0049] (5) Mix the particles weighed in (4) and put them into the feeding funnel of the extruder. The feeding temperature is 220°C, and the discharging temperature is 200°C. After cooling, the red perovskite quantum dot diffusion plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com