Plastic roll-forming heat exchange plate and manufacturing process

A manufacturing process and technology of heat exchange plates, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of short service life, poor thermal conductivity, high price, etc., and achieve low manufacturing cost, mechanical Strong strength and small heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

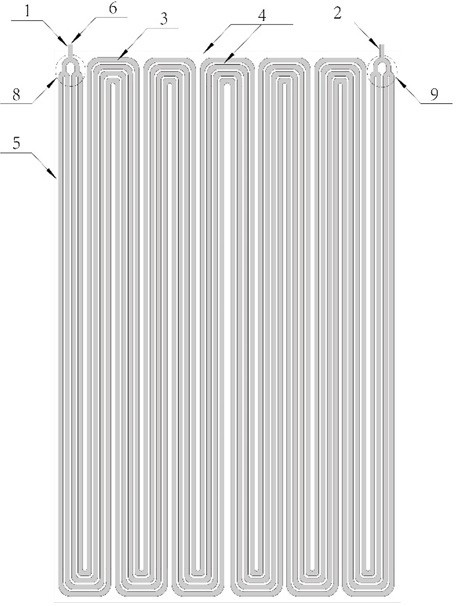

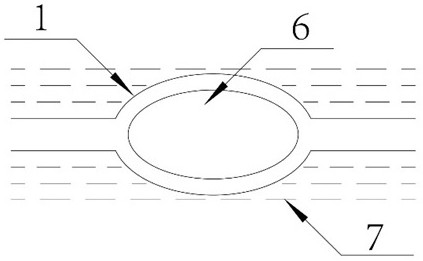

[0032] A heat exchange plate formed by plastic inflation, comprising: a heat exchange plate body 5, a heat transfer medium 6 and a heat transfer medium 2 7, the circulation channel of the heat transfer medium 6 is formed inside the heat exchange plate body 5, and the The outer surface of the heat exchange plate body 5 is used for the circulation of the heat transfer medium 2 7 .

[0033] Specifically, the heat exchange plate body 5 includes an inlet manifold 1, an outlet manifold 2 and a plurality of hollow channels 3, the inlet manifold 1 communicates with the entrance of the hollow channels 3, the hollow channels 3 are arranged in a serpentine loop, and the hollow channels 3 The outlet of the outlet is communicated with the outlet main pipe 2.

[0034] Further, the inlet main pipe 1 communicates with the inlet of each hollow channel 3 in the multiple hollow channels 3 through a flow diversion structure 8, and the outlet of each hollow channel 3 in the multiple hollow channel...

Embodiment 2

[0045] A manufacturing process of a plastic inflation forming heat exchange plate, comprising the following preparation steps:

[0046] S1. Prepare heat exchange plate mold:

[0047] The heat exchange plate mold is composed of two left and right moulds. The shape of the inner cavity formed by the clamping of the two molds matches the shape of the heat exchange plate. The mold is made of alloy aluminum.

[0048] S2. Extrusion parison: feed glass fiber modified thermoplastic polyurethane particles into the hopper of a single-screw extruder or twin-screw extruder, extrude a hollow plastic tube with a certain diameter in a semi-molten state, and then feed it into The storage tank is kept warm to prevent cooling and deformation. The diameter of the extruded hollow plastic tube is determined according to the circumference of the transverse section of the heat exchange plate, and the thickness of the extrusion is determined according to the pressure required by the hollow channel of th...

Embodiment 3

[0056] A manufacturing process of a plastic inflation forming heat exchange plate, comprising the following preparation steps:

[0057] S1. Prepare heat exchange plate mold:

[0058] The heat exchange plate mold is composed of two left and right moulds. The shape of the inner cavity formed by the clamping of the two molds matches the shape of the heat exchange plate. The mold is made of alloy aluminum.

[0059] S2. Extrusion parison: feed glass fiber modified polypropylene particles into the hopper of a single-screw extruder or twin-screw extruder, extrude a hollow plastic tube with a certain diameter in a semi-molten state, and then send it into the storage The material cylinder is kept warm to prevent cooling and deformation. The diameter of the extruded hollow plastic tube is determined according to the perimeter of the transverse section of the heat exchange plate produced, and the thickness of the extrusion is determined according to the pressure required by the hollow ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com