Environment-friendly novel hemp fiber degumming technology

An environmentally friendly technology for hemp fiber, applied in the field of degumming of new environmentally friendly hemp fiber, can solve the problems of large environmental pollution, large alkali consumption, short time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

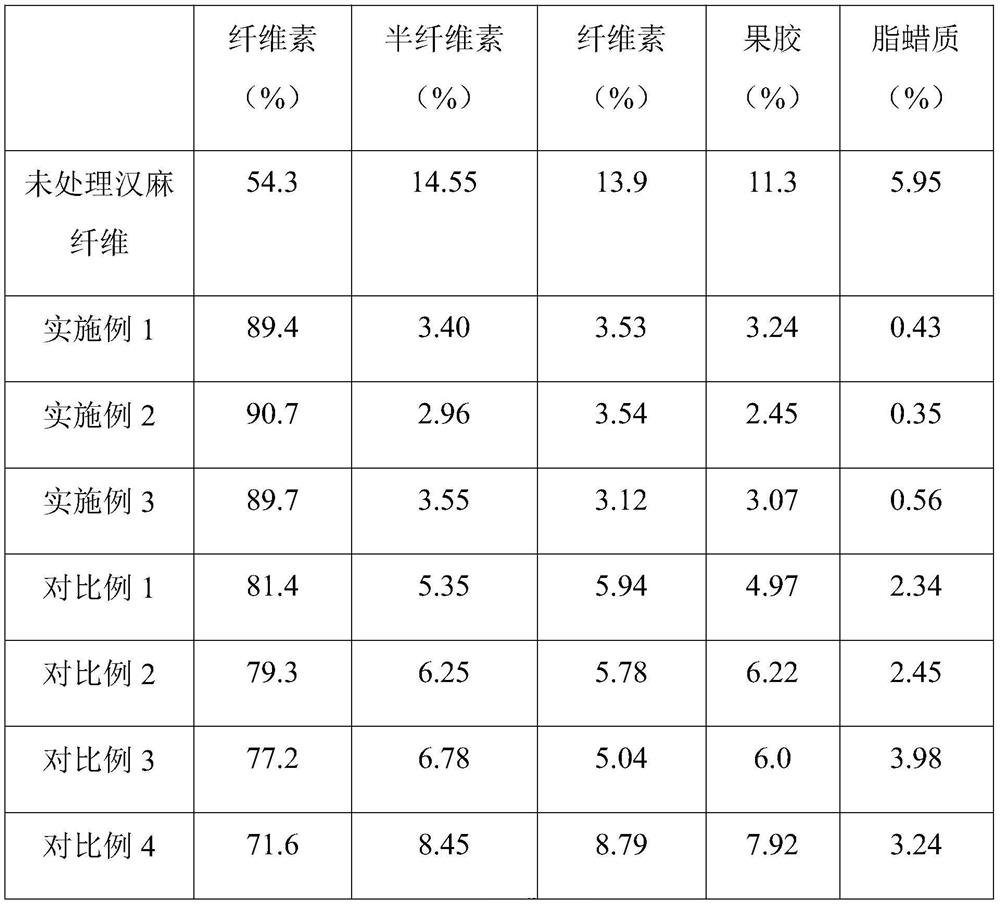

Examples

Embodiment 1

[0020] A kind of degumming technology of environment-friendly new hemp fiber, the process of the degumming technology of described environment-friendly new hemp fiber is:

[0021] (1) Disperse the hemp fiber in pure water 10 times the mass of the hemp fiber and perform ultrasonic treatment. The ultrasonic frequency is 40kHz, the temperature is 60°C, and the treatment time is 5min. To obtain pretreated hemp fiber; mix chitosan and 1-hydroxybenzotriazole according to the mass ratio of 1:0.65 and disperse them in deionized water 50 times the quality of chitosan, and add chitosan mass 0.2 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride with 4 times the mass of N-acetyl-L-cysteine and chitosan, and with 1mol / L Adjust the pH to 5 with sodium hydroxide, stir and react at 400 rpm for 2 h at room temperature, precipitate with absolute ethanol and wash 3 times with deionized water, and dry in a 50° C. oven for 3 h to obtain mercapto-chitosan. The hemp fiber was dispersed ...

Embodiment 2

[0025] A kind of degumming technology of environment-friendly new hemp fiber, the process of the degumming technology of described environment-friendly new hemp fiber is:

[0026] (1) Disperse the hemp fiber in pure water 15 times the mass of the hemp fiber and perform ultrasonic treatment. The ultrasonic frequency is 50kHz, the temperature is 70°C, and the treatment time is 5min. To obtain pretreated hemp fiber; mix chitosan and 1-hydroxybenzotriazole according to the mass ratio of 1:0.68 and disperse them in deionized water 50 to 80 times the quality of chitosan, stir evenly and add chitosan 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride with 0.25 times the quality of N-acetyl-L-cysteine and 5 times the quality of chitosan, and use 1mol / L of sodium hydroxide was used to adjust the pH to 5.5, stirred and reacted at 500 rpm for 2.5 h at room temperature, precipitated with absolute ethanol and washed 4 times with deionized water, and dried for 3.5 h in a 50° C. ...

Embodiment 3

[0030] A kind of degumming technology of environment-friendly new hemp fiber, the process of the degumming technology of described environment-friendly new hemp fiber is:

[0031] (1) Disperse the hemp fiber in pure water 20 times the mass of the hemp fiber and perform ultrasonic treatment. The ultrasonic frequency is 60kHz, the temperature is 80°C, and the treatment time is 6min. To obtain pretreated hemp fiber; mix chitosan and 1-hydroxybenzotriazole according to the mass ratio of 1:0.7 and disperse them in deionized water 80 times the quality of chitosan, and add chitosan mass 0.3 after stirring evenly 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride with 5.5 times the mass of N-acetyl-L-cysteine and chitosan, and with 1mol / L Adjust the pH to 6 with sodium hydroxide, stir and react at room temperature at 600rpm for 3h, precipitate with absolute ethanol and wash 5 times with deionized water, and dry in a 50°C drying oven for 4h to obtain mercapto-chitosan. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com