Production method of attapulgite gelatin for coating thickener

A paint thickener and attapulgite technology, which is applied in the direction of chemical instruments and methods, coatings, fibrous fillers, etc., can solve the problems of reducing thixotropic index, no viscosity, etc., to increase dosage, improve competitiveness, expand The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

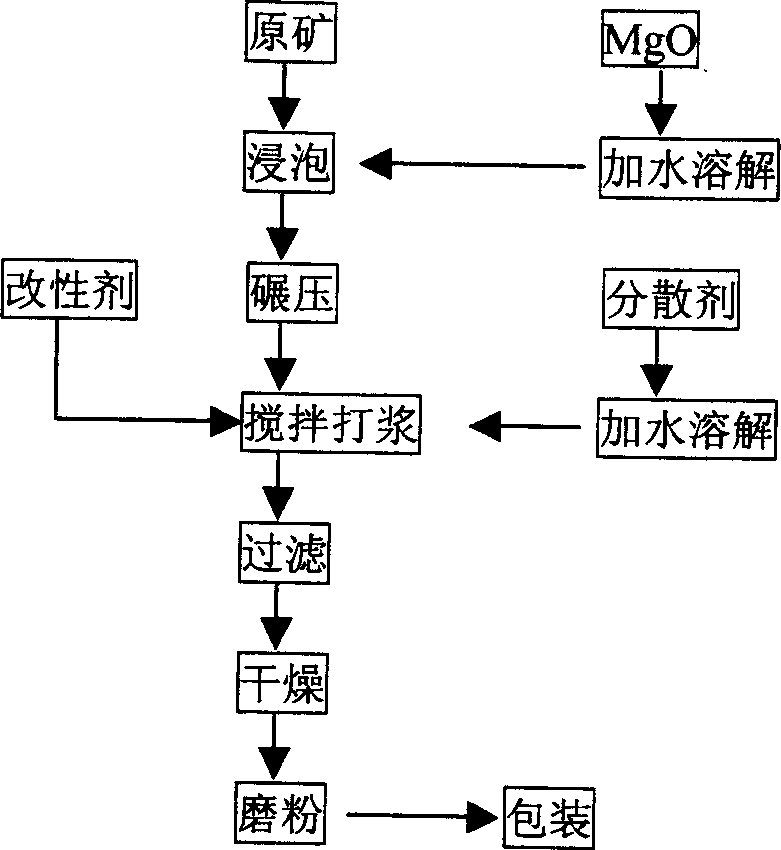

Image

Examples

example 1

[0023] Example 1: First, select attapulgite concentrated ore 100kg, add water and additives to soak for 5 days, additive MgO 2kg, water 900kg; then, pressure 50-70 kg / cm 2 Rolling to get wet material with 40% water content, soak the wet material again for 2-3 days, and roll the wet material two or three times in a row; secondly, dry at 120°C to get dry material with 8% water content; finally, grind the dry material Attapulgite gel was obtained with 500 mesh.

[0024] Among them, when the raw material of attapulgite is coarse ore, the step of stirring and beating is added after the first rolling, that is, the wet beneficiation step. The wet ore washing is to add water and dispersant to the wet material and stir. The weight of the dispersant sodium tripolyphosphate is 0.1kg, water The weight is 900kg.

[0025] Wherein, the solvent-based paint thickener is produced by adding modifier 12 alkyltrimethylammonium chloride in the soaking or stirring beating process, and the weight of...

example 2

[0027] Example 2: First, select 100kg of attapulgite concentrated ore, add water and additives to soak for 6 days, the weight of additive MgO is 3kg, and the water is 900kg; then, the pressure is 50-70 kg / cm 2 Rolling to get wet material with 50% water content, soak the wet material again for 2-3 days, and roll two or three times in a row to get wet material; secondly, dry at 100°C to get dry material with 10% water content; finally, grind the dry material Attapulgite gel was obtained with 500 mesh.

[0028] Among them, when the raw material of attapulgite is coarse ore, the step of stirring and beating is added after the first rolling, that is, the wet beneficiation step. The wet beneficiation is to add water and dispersant to the wet material for stirring. The dispersant sodium phosphate weighs 0.5kg and water 900kg.

[0029] Among them, the solvent-based paint thickener is produced by adding modifier 16 alkyltrimethylammonium chloride in the soaking or stirring beating proc...

example 3

[0031] Example 3: First, apply 100kg of attapulgite concentrated ore, add water and additives to soak for 7 days, the additive MgO weight is 4kg, and the water is 900kg; then, the pressure is 50-70 kg / cm 2 Rolling to obtain a wet material with a moisture content of 55%, soaking the wet material again for 2-3 days, rolling two or three times in a row to obtain a wet material; secondly, filtering the wet material, drying at a temperature of 80°C to obtain a dry material with a moisture content of 8%; finally, The dry material was pulverized into 500 mesh to obtain attapulgite gel.

[0032] Among them, when the raw material of attapulgite is coarse ore, the step of stirring and beating is added after rolling, that is, the wet beneficiation step. The wet beneficiation is to add water and dispersant to the wet material. The dispersant is 1.0kg of phosphate and 900kg of water.

[0033] Wherein, the solvent-based paint thickener is produced by adding modifier 18 alkyltrimethylammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com