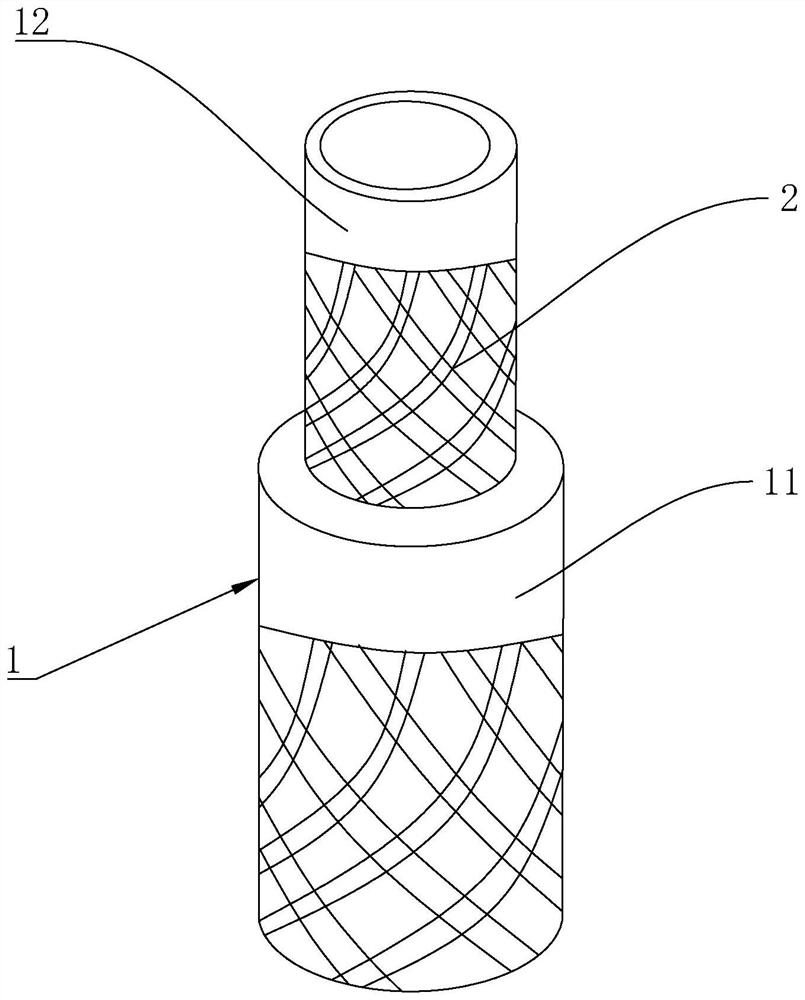

Memory rubber with high cohesiveness as well as preparation method and application thereof

A cohesive, rubber-based technology, applied in mechanical equipment, pipelines to prevent damage/abrasion, pipeline protection, etc., can solve problems such as poor viscosity of memory rubber, gas leakage, easy to break, etc., to achieve good wear resistance and elasticity , improve adhesion, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of memory rubber with high cohesiveness, comprising the following steps:

[0054] Put 20 parts of rubber and 10 parts of polycarbonate into a horizontal mixer, and stir for 1 hour at a speed of 40r / min to obtain a mixture; put 1 part of antioxidant 1010 and 5 parts of terpene resin into a horizontal mixer at an internal speed of Stir at a speed of 60r / min for 1 hour, and extrude through an extruder to obtain an extrudate; put 1 part of sulfur and 1 part of stearic acid and the extrudate into a rubber injection molding machine for vulcanization, cool for 2 hours, and obtain a memory rubber.

Embodiment 2

[0056] A preparation method of memory rubber with high cohesiveness, comprising the following steps:

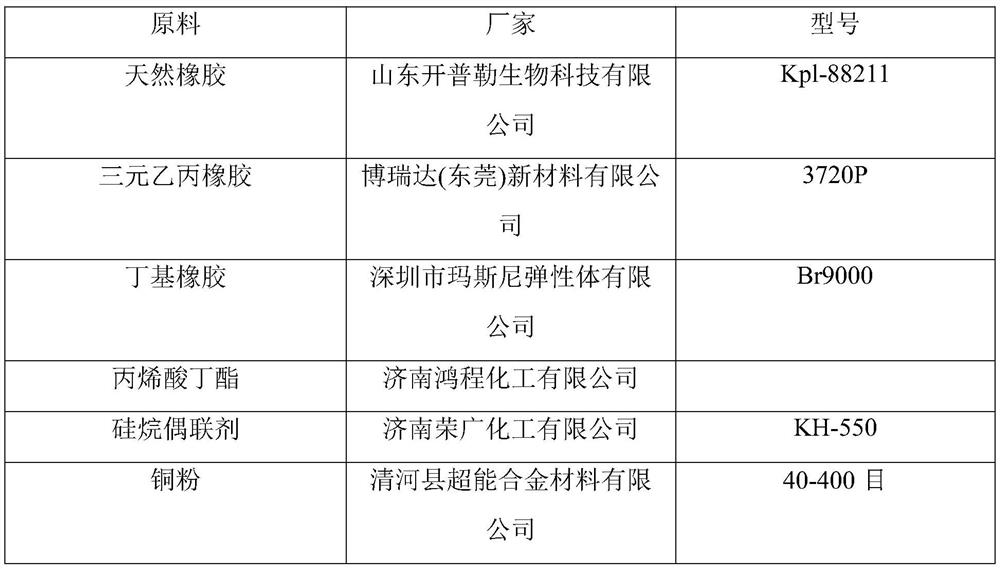

[0057] Put 20 parts of rubber and 10 parts of polycarbonate into a horizontal mixer, and stir for 1 hour at a speed of 40r / min to obtain a mixture; put 1 part of antioxidant DLTP and 5 parts of rosin glyceride into a horizontal mixer at an internal speed of Stir at a speed of 60r / min for 1 hour, and extrude through an extruder to obtain an extrudate; put 1 part of sulfur and 1 part of stearic acid and the extrudate into a rubber injection molding machine for vulcanization, cool for 2 hours, and obtain a memory Rubber; Wherein, rubber is modified natural rubber, and modified natural rubber is prepared by the following steps:

[0058] S1: Add 30 parts of natural rubber, 5 parts of EPDM rubber and 10 parts of butyl rubber into 50 parts of butyl acrylate, heat and stir for 2 hours at a temperature of 50 ° C and a speed of 30 r / min to obtain a stirred thing;

[0059] S2: Mix 10 ...

Embodiment 3

[0062] A preparation method of memory rubber with high cohesiveness, comprising the following steps:

[0063] Put 20 parts of rubber and 10 parts of polycarbonate into a horizontal mixer, and stir for 1 hour at a speed of 40r / min to obtain a mixture; put 1 part of antioxidant 1010 and 5 parts of polyethylene into a horizontal mixer with an internal speed of Stir at a speed of 60r / min for 1 hour, and extrude through an extruder to obtain an extrudate; put 1 part of sulfur and 1 part of stearic acid and the extrudate into a rubber injection molding machine for vulcanization, and cool for 2 hours to obtain a memory rubber ; Wherein, rubber is modified natural rubber, and modified natural rubber is prepared by the following steps:

[0064] S1: Add 30 parts of natural rubber, 5 parts of EPDM rubber and 10 parts of butyl rubber into 50 parts of butyl acrylate, heat and stir for 2 hours at a temperature of 50 ° C and a speed of 30 r / min to obtain a stirred thing;

[0065] S2: Mix 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com