Multi-element rare earth eutectic high-temperature superconducting raw material as well as preparation method and application thereof

A technology of high-temperature superconductivity and raw materials, applied in the preparation of aldehyde/ketone chelates, metal material coating technology, organic chemistry, etc., can solve problems such as failure to meet market demand, poor particle distribution, unevenness, etc., and achieve improvement Thin-film superconductivity, large steric hindrance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a multi-component rare earth eutectic high-temperature superconducting raw material, which comprises the following steps:

[0040] 1), preparation of rare earth nitrate solution: with chemical formula Y a Gd b Dy c SM d Prepare the nitrate solution containing Y, Gd, Sm, and Dy respectively, and mix the four kinds of rare earth nitrate solutions, stir for 1-2 hours, filter and let stand for use; among them, a, b, The ratio of c and d is (0.31~0.53):(0.35~0.46):(0.09~0.23):(0.05~0.12);

[0041] 2), (Y a Gd b Dy c SM d )(tmhd) 3 Synthesis: Add a certain amount of TMHD to CH 3 OH and H 2 In the mixed solution of O, and the mass ratio of the two is 0.1-0.2:1, heat the mixed solution to 65-80°C; after the mixed solution is clarified, drop 3-8% sodium hydroxide solution into it to adjust The pH value of the solution is set to be 6.5-7.5, and stirred for 1-2 hours to obtain a TMHD solution; slowly add the above-mentioned ...

Embodiment 1

[0050] a. Rare earth nitrate solution preparation: with chemical formula Y 0.42 Gd 0.38 Dy 0.13 SM 0.07 Prepare the nitrate solution containing Y, Gd, Sm, and Dy respectively in the molar content ratio of each element, and mix the four kinds of rare earth nitric acid solutions, stir for 2h, filter and stand for use;

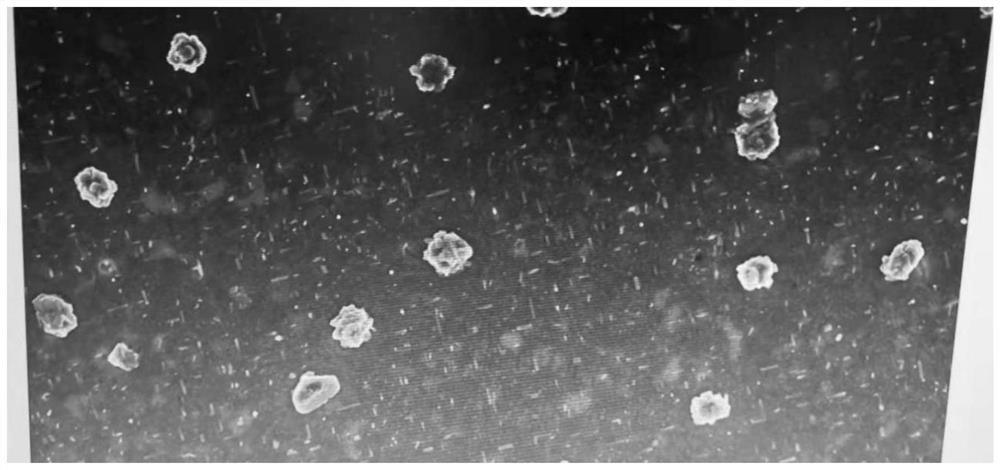

[0051] b.(Y 0.42 Gd 0.38 Dy 0.13 SM 0.07 )(tmhd) 3 Synthesis: add a certain amount of TMHD to CH 3 OH and H 2 In the mixed solution of O, and the mass ratio of the two is 0.1:1, heat the mixed solution to 65°C; after the mixed solution is clarified, drop 5% sodium hydroxide solution into it, and adjust the pH value of the solution to 6.5 , stirred for 1 h; the above-mentioned nitrate solution containing Y, Gd, Sm, and Dy was slowly added to the TMHD solution, kept stirring for 3 h, then stopped heating, a light yellow precipitate appeared in the reaction kettle, left standing for 3 h, and the solid-liquid was separated; Then, the solid matter was vacuum...

Embodiment 2

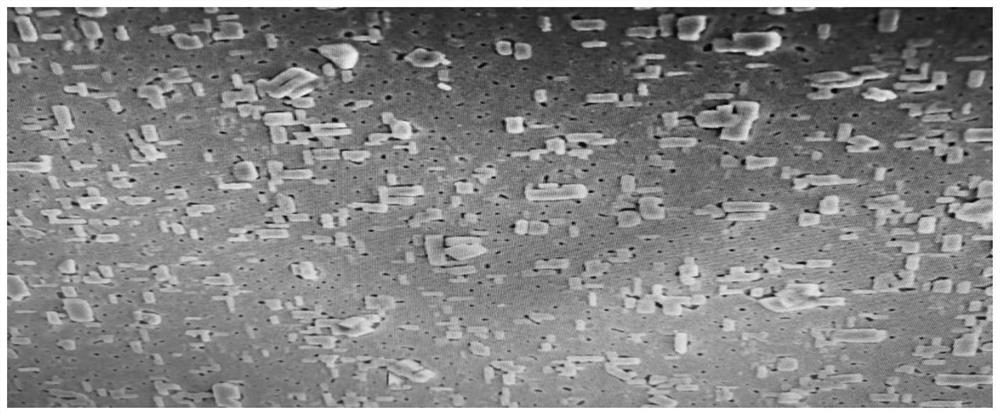

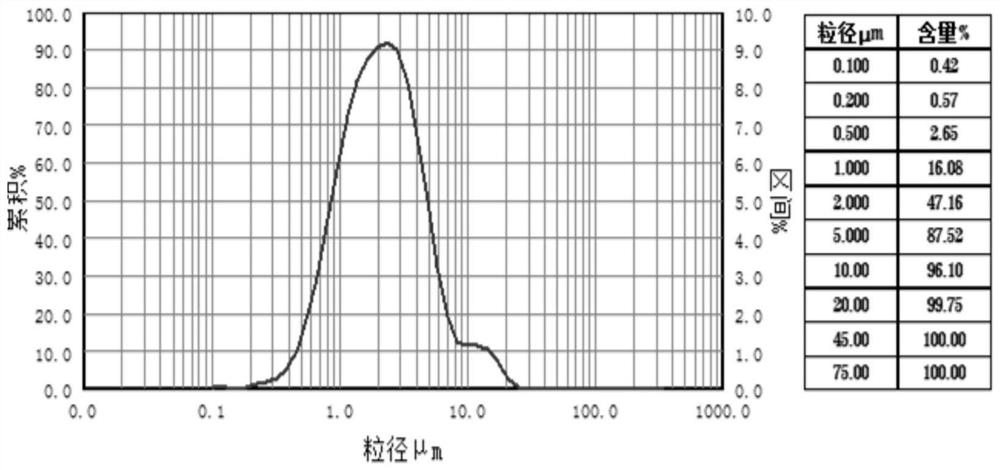

[0054] A kind of preparation method of multi-element rare earth eutectic high-temperature superconducting raw material is provided below, and it comprises the following steps: press YBa 2 Cu 3 o 7-d In the formula, the mol ratio of Y:Ba:Cu=1:2:3 calculates the quality of each corresponding M0 source, then Y (tmhd) 3 、Ba(tmhd) 2 、Cu(tmhd) 2 Add 4250ml of tetrahydrofuran, stir and filter evenly, make a superconducting thin film on M1, after silver plating and annealing, test the critical current as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com