C50 high-strength resin concrete and preparation process thereof

A resin concrete, high-strength technology, applied in the field of high-strength concrete, can solve the problems of difficulty in mixing, poor cohesion, poor workability of concrete, etc., and achieve the effects of high mixing ease, improved interface state, and high mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

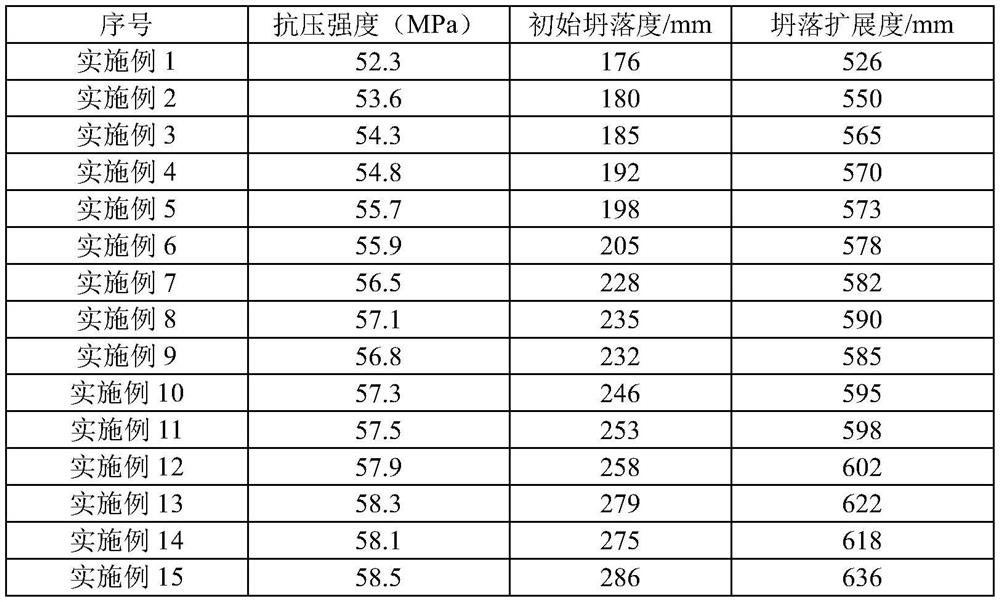

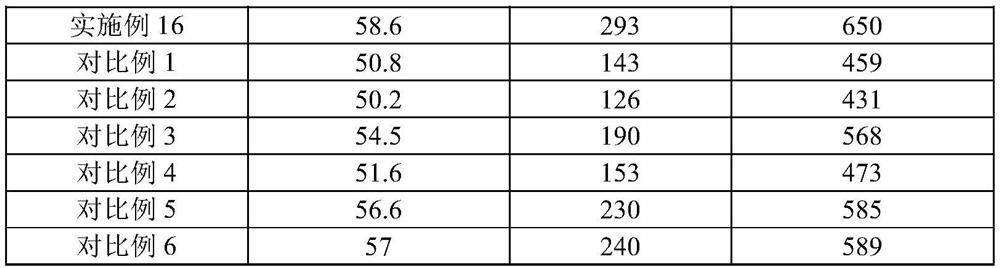

Examples

Embodiment 1

[0042] The C50 high-strength resin concrete in this embodiment is made of the following raw materials: 220kg of cement, 90kg of mineral powder, 70kg of fly ash, 5kg of silica fume, 720kg of sand, 950kg of coarse aggregate, 7kg of admixture, 165kg of water, compound Resin 100kg, curing agent 8kg. The composite resin is composed of liquid phenolic resin and solid phenolic resin in a mass ratio of 15:7.

[0043] Among them, the cement is ordinary Portland cement with the label 50.5. The specific surface area of mineral powder is 400㎡ / kg. Fly ash is a first-class fly ash. The specific surface area of silica fume is 22000㎡ / kg. The admixture is a high-efficiency polycarboxylate water reducer with a water reducing rate of 25%. The fineness modulus of the sand is 2.5. The curing agent is NL curing agent. The liquid phenolic resin is 2127 phenolic resin with a solid content of 50%. The solid phenolic resin is 2123 phenolic resin powder with an average particle size of 100 μm...

Embodiment 2

[0048] The C50 high-strength resin concrete in this embodiment is made of the following raw materials: 250kg of cement, 120kg of mineral powder, 90kg of fly ash, 15kg of silica fume, 780kg of sand, 1000kg of coarse aggregate, 10kg of admixture, 180kg of water, compound Resin 120kg, curing agent 15kg. The composite resin is composed of liquid phenolic resin and solid phenolic resin in a mass ratio of 15:7.

[0049]Among them, the cement is ordinary Portland cement with the label 50.5. The specific surface area of mineral powder is 400㎡ / kg. Fly ash is a first-class fly ash. The specific surface area of silica fume is 22000㎡ / kg. The admixture is a high-efficiency polycarboxylate water reducer with a water reducing rate of 25%. The fineness modulus of the sand is 2.5. The curing agent is NL curing agent. The liquid phenolic resin is 2127 phenolic resin with a solid content of 50%. The solid phenolic resin is 2123 phenolic resin powder with an average particle size of 10...

Embodiment 3

[0054] The C50 high-strength resin concrete in this embodiment is made of the following raw materials: 250kg of cement, 110kg of mineral powder, 80kg of fly ash, 12kg of silica fume, 750kg of sand, 980kg of coarse aggregate, 8kg of admixture, 170kg of water, compound Resin 110kg, curing agent 12kg. The composite resin is composed of liquid phenolic resin and solid phenolic resin in a mass ratio of 15:7.

[0055] Among them, the cement is ordinary Portland cement with the label 50.5. The specific surface area of mineral powder is 400㎡ / kg. Fly ash is a first-class fly ash. The specific surface area of silica fume is 22000㎡ / kg. The admixture is a high-efficiency polycarboxylate water reducer with a water reducing rate of 25%. The fineness modulus of the sand is 2.5. The curing agent is NL curing agent. The liquid phenolic resin is 2127 phenolic resin with a solid content of 50%. The solid phenolic resin is 2123 phenolic resin powder with an average particle size of 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com