Environment-friendly root-puncture-resistant PVC (polyvinyl chloride) waterproof coiled material and preparation method thereof

A waterproofing membrane, root puncture resistance technology, applied in building insulation materials, chemical instruments and methods, roofing using flexible materials, etc., can solve problems such as insufficient environmental protection performance and root puncture resistance of PVC waterproofing membranes Root puncture resistance, good fungal corrosion resistance, high puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

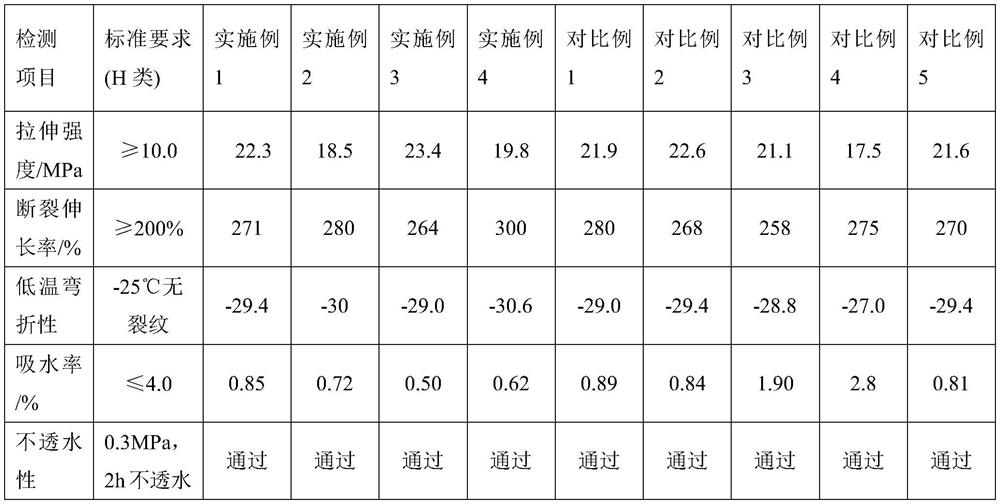

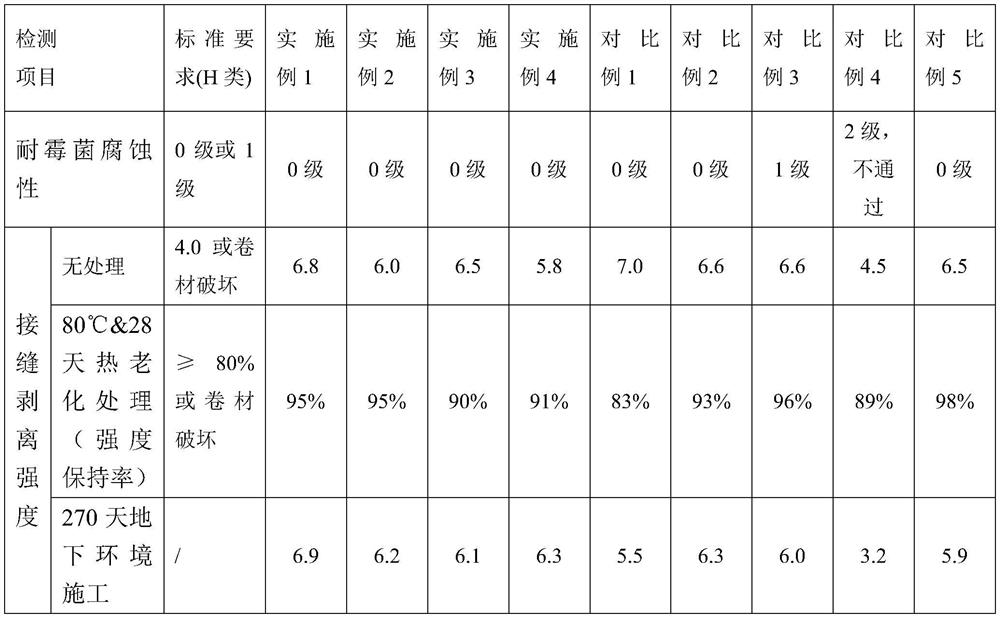

Examples

Embodiment 1

[0046] Preparation of elastomer film layer: 100 parts of ethylene-propylene elastomer resin, 2 parts of filler and 0.5 part of chemical root inhibitor are respectively added to the twin-screw extruder through a weight-loss metering feeding system, and the barrel temperature is set at 170- 180°C, through the extruder for plasticization, extrusion, and drawing, and then through the pelletizer to prepare the root-blocking modified ethylene-propylene elastomer resin, and finally the root-blocking modified ethylene-propylene elastomer resin is prepared by blow molding into an elastomeric film;

[0047] Preparation of root-inhibiting plasticizer: Add 100 parts of chlorinated palm oil methyl ester into the reaction kettle, heat up to 80-82°C, add 2 parts of chemical root-inhibiting agent, stir at high speed for 60 minutes, cool down to room temperature, and prepare root-inhibiting plasticizer;

[0048] Preparation of PVC sheet layer: Add 100 parts of accurately weighed PVC resin pow...

Embodiment 2

[0059] Preparation of elastomer film layer: 100 parts of ethylene-propylene elastomer resin, 2 parts of filler and 0.5 part of chemical root inhibitor are respectively added to the twin-screw extruder through a weight-loss metering feeding system, and the barrel temperature is set at 170- 180°C, through the extruder for plasticization, extrusion, and drawing, and then through the pelletizer to prepare the root-blocking modified ethylene-propylene elastomer resin, and finally the root-blocking modified ethylene-propylene elastomer resin is prepared by blow molding into an elastomeric film;

[0060] Preparation of root-inhibiting plasticizer: Add 100 parts of chlorinated palm oil methyl ester into the reaction kettle, heat up to 80-82°C, add 1.5 parts of chemical root-inhibiting agent, stir at high speed for 60 minutes, cool down to room temperature, and prepare root-inhibiting plasticizer;

[0061] Preparation of PVC sheet layer: Add 100 parts of accurately weighed PVC resin p...

Embodiment 3

[0072] Preparation of elastomer film layer: 100 parts of ethylene-propylene elastomer resin, 3 parts of filler and 0.5 part of chemical root inhibitor are respectively added to the twin-screw extruder through a weight-loss metering feeding system, and the barrel temperature is set at 170- 180°C, through the extruder for plasticization, extrusion, and drawing, and then through the pelletizer to prepare the root-blocking modified ethylene-propylene elastomer resin, and finally the root-blocking modified ethylene-propylene elastomer resin is prepared by blow molding into an elastomeric film;

[0073] Preparation of root-blocking plasticizer: Add 100 parts of methyl chlorostearate into the reaction kettle, raise the temperature to 80-82°C, add 3 parts of chemical root-blocking agent, stir at high speed for 60 minutes, cool down to room temperature, and prepare the root plasticizer;

[0074] Preparation of PVC sheet layer: Add 100 parts of accurately weighed PVC resin powder, 4 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com