Technological method for extracting 1-deoxynojirimycin from mulberry leaf

A technology of deoxynojirimycin and process method, which is applied in the field of extraction and preparation of 1-deoxynojirimycin, which can solve the problems of solvent residue and achieve the effect of reducing the amount of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]1 kg of mulberry leaves was crushed, passed through a 20-mesh sieve, extracted twice with 10 kg of deionized water, the temperature was controlled at about 95°C, and extracted twice, the first extraction was 2 hours, and the second extraction was 1 hour. Combine the extracts, filter, and concentrate to about 800ml to obtain liquid A; then add 3000ml of 95% ethanol to liquid A, let it stand for 18 hours, filter to remove the precipitate, put the mother liquor in a rotary evaporator to concentrate, adjust the temperature of the water bath to 60°C, When the vacuum degree is above 0.05MPa, ethanol is recovered and concentrated to 800ml to obtain liquid B.

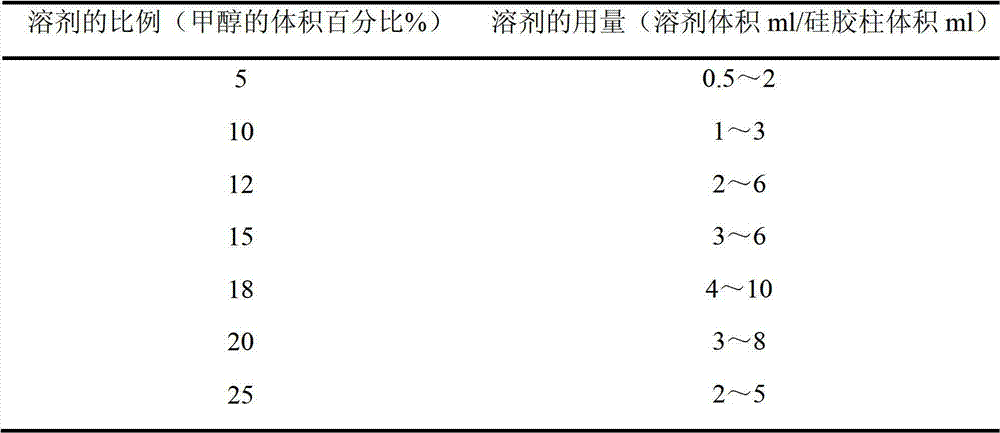

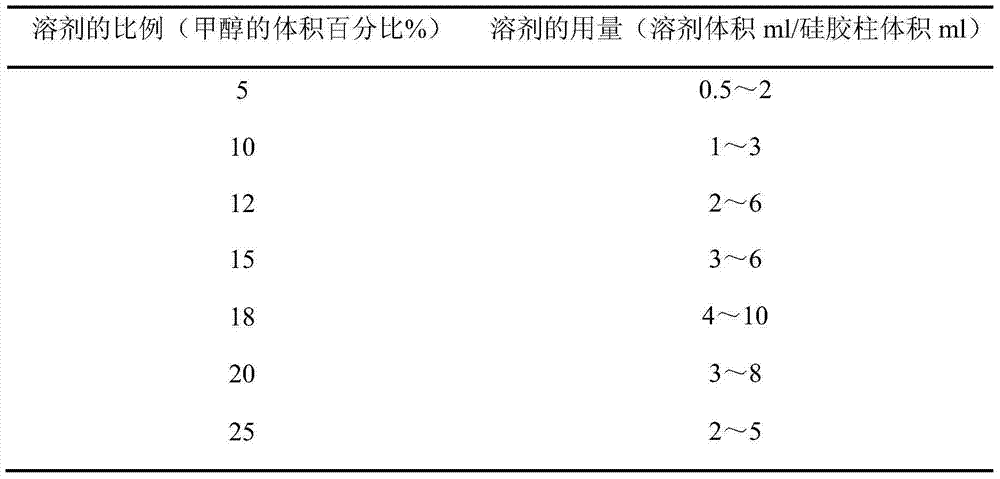

[0029] Soak 1000g of macroporous resin in 4000ml of ethanol for 6 hours, then soak in 3000ml of ethanol for 3 hours, then soak in 2000ml of ethanol for 2 hours, wash with alcohol to remove impurities, then wash with water to remove the ethanol remaining in the macroporous resin until there is no alcohol smell , and finall...

Embodiment 2

[0035] 800g of mulberry leaves were crushed, passed through a 30-mesh sieve, and refluxed with 12kg of 20% ethanol for 3 times, the temperature was controlled at about 85°C, the first extraction was 2 hours, the second time was 1 hour, the third time was 1 hour, combined The extract was filtered and concentrated to about 1600ml to obtain liquid A; then, 1600ml of absolute ethanol was added to liquid A, left for 10 hours, and the precipitate was removed by centrifugation. When the concentration is above 0.05MPa, recover ethanol and concentrate to 1600ml to obtain liquid B.

[0036] 1600g macroporous adsorption resin is first soaked in 3000ml of ethanol for 5 hours, then soaked in 2000ml of ethanol for 3 hours, then soaked in 1600ml of ethanol for 1 hour. , and finally wet packed into the chromatography column (diameter x height, 60mm x 900mm). Add liquid B to the treated D101 macroporous adsorption resin chromatography column, let it stand for 4 hours, then elute with deionize...

Embodiment 3

[0042] Crush 400g of mulberry leaves, pass through a 20-mesh sieve, extract twice with 6kg of deionized water, control the temperature at about 90°C, extract for 2 hours for the first time, and 1 hour for the second time, combine the extracts, filter, and concentrate to 800ml , then add 3200ml of 95% ethanol to the concentrated solution, leave it for 12 hours, filter to remove the precipitate, put the mother liquor into a rotary evaporator to concentrate, adjust the temperature of the water bath to 75°C, and the vacuum degree to 0.07MPa, recover the ethanol, concentrate to 800ml, that is Get liquid B.

[0043] Soak 1200g macroporous resin in 4000ml of ethanol for 4 hours, then soak in 2000ml of ethanol for 2 hours, then soak in 1500ml of ethanol for 1 hour. , and finally wet packed into the chromatographic column (diameter x height, 80mm x 650mm). Add liquid A to the treated HPD-722 macroporous adsorption resin chromatography column, let it stand for adsorption for 3 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com