Gradient pore structure silk fibroin film and preparation method thereof

A technology of silk fibroin and regenerated silk fibroin, which is applied to the field of silk fibroin film with gradient pore structure and its preparation, can solve the problems of repeatability, weak interaction, complicated operation process, etc., and achieves excellent mechanical properties, Excellent mechanical properties and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The concentration of 0.5 wt% of the lithium chloride-formic acid solution was configured, and 0.4 g of delayed silk was dissolved in 7.8 mL of the above solution, and the oscillation of the ultrasonic cleaning machine was oscillated to obtain a regenerative silk fibroin solution.

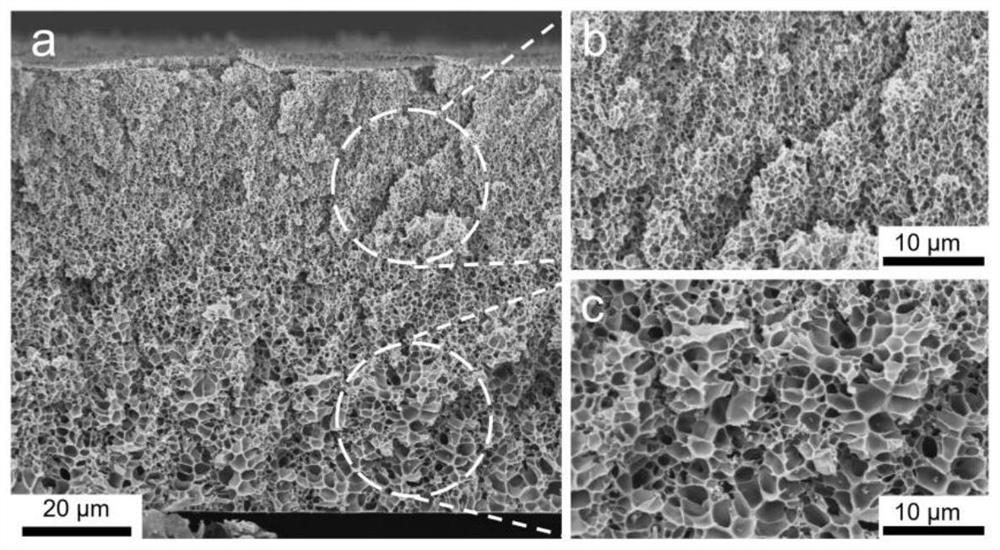

[0040]With a clean PET substrate, it is used for 1 min using ultraviolet ozone, and the scraper wiper blade has a thickness of 10 μm, scraping a layer of regenerated silk fibroin moist film and dried; the dry film is placed in water soaked in water, then Contains with the basal and silk fibroid membrane to refrigerate the refrigerator; add the frozen silk fibroin film into a freeze dryer for freeze drying; use mechanical stripping mode, the dry gradient aperture protein film is peeled off with substrate That is, a self-supporting gradient aperture protein film is obtained, and the film formation thickness is about 10 μm, and the varying variation in the thickness direction ranges from 500 nm to 5...

Embodiment 2

[0042] The concentration of 8.7 wt% lithium bromide-formic acid solution was configured, and 2.5 g of delayed silk was dissolved in 5.7 ml of the above solution, placed in an ultrasonic cleaning machine to oscillate 2 h, resulting in a regenerative silk fibroin solution.

[0043] Using a clean polyimide PI substrate, an oxygen plasma washed 5 min, and a blade scraper wiper had a thickness of 500 μm, scraping a layer of silk fibroidin moist film and dried; 1H, then inserted into the -20 ° C refrigerator in conjunction with the basal and silk fibroin gel, the frozen silk fibroin film was placed in a freeze dryer for freeze drying; a mechanical stripping method, a dry gradient aperture protein film The gradient aperture protein film is obtained from the substrate to obtain a self-supporting gradient, and the film film has a film thickness of about 1000 μm, and the varying variation in the thickness direction is 200 nm-10 μm in the thickness direction.

Embodiment 3

[0045] The concentration of 4.8 wt% of the calcium chloride-formic acid solution was configured, and 1.3 g of delayed silk was dissolved in 6.8 ml of the above solution, placed in an ultrasonic cleaning machine to oscillate 1 h, resulting in a regenerative silk fibroin solution.

[0046] With a clean PET substrate, a four-sided preparator having a thickness of 300 μm is used, and the silkwater wet film is applied and dried; the dry film is placed in water for 10 min, and then together with the base and silk fibroin gel film directly into the frozen Dryer; through -50 ° C cold trap and low vacuum effects, the surface of the silk fibroin film is spontaneously nucleated, and the in situ freeze is carried out; the dry gradient, the dried gradient, the film is peeled off. The self-supporting gradient aperture protein film is obtained, and the film film has a film thickness of about 80 μm, and the aperture in the thickness direction ranges from 200 nm to 5um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com