Building rubber particle modified sound insulation mortar and preparation method thereof

A technology for rubber particles and construction, which is applied in the field of rubber particle-modified soundproof mortar for construction and its preparation, can solve the problems of poor compatibility between rubber particles and mortar, inability of rubber particles to be uniformly dispersed, and reduce the safety performance of mortar, etc. Compatibility, improving hydrophobicity, and ensuring the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

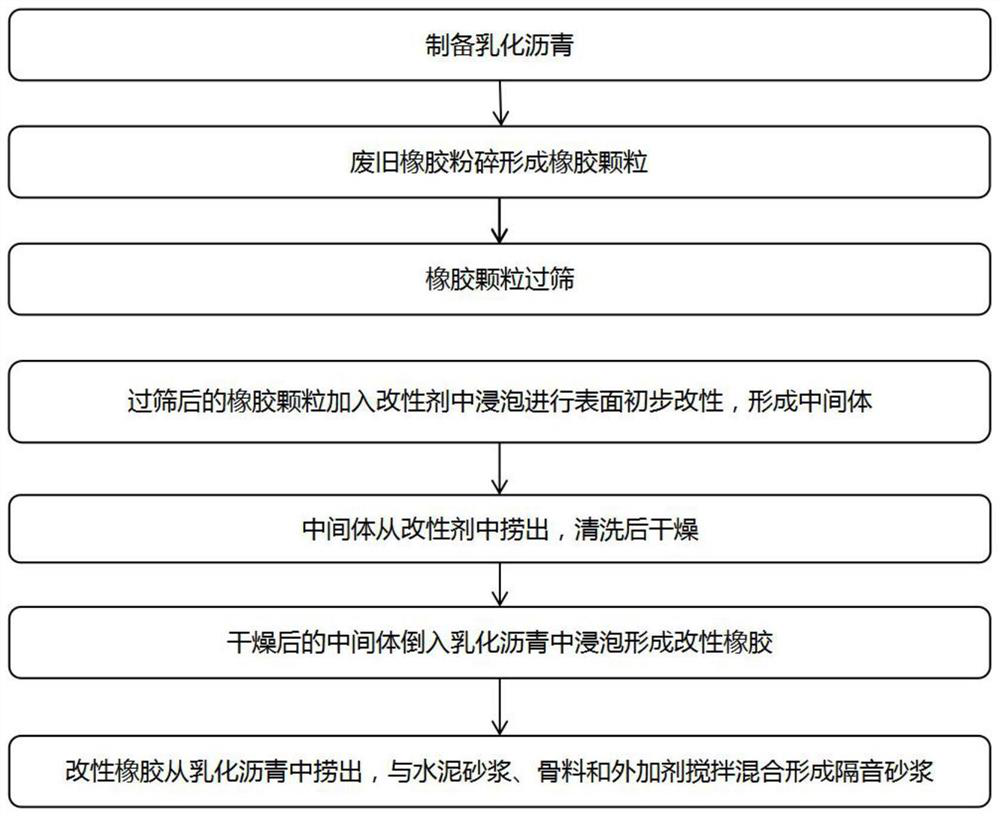

[0042] A method for preparing rubber particle modified soundproof mortar for construction, comprising the following steps:

[0043] Step 1: Prepare emulsified asphalt, emulsified asphalt includes 58-63 parts of base asphalt or modified asphalt; 37-42 parts of water; 1.4-2.5 parts of emulsifier; 0.05-0.5 parts of stabilizer; 0.01-0.5 parts of thickener; pH Conditioner 0.1-2.0 parts; defoamer 0.1-1.0 parts, asphalt includes coal tar pitch, petroleum asphalt and natural asphalt, etc., emulsifiers include alkylamines, amides, imidazolines, aminated lignins, quaternary ammonium salts Stabilizers include calcium chloride, magnesium chloride, barium chloride, etc., thickeners include amines, polyvinyl alcohol, cellulose, polyacrylate, etc., pH regulators include hydrochloric acid, sulfuric acid, nitric acid, glacial acetic acid, lemon Acid etc., defoamer includes emulsified silicone oil, higher carbon alcohol fatty acid ester compound etc., select petroleum asphalt as pitch in the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com